Bolometer and manufacturing method thereof

A measuring meter and radiant heat technology, applied in the field of infrared detectors, can solve the problems of flexible design structure, and achieve the effect of flexible design, improved flexibility, and optimized performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

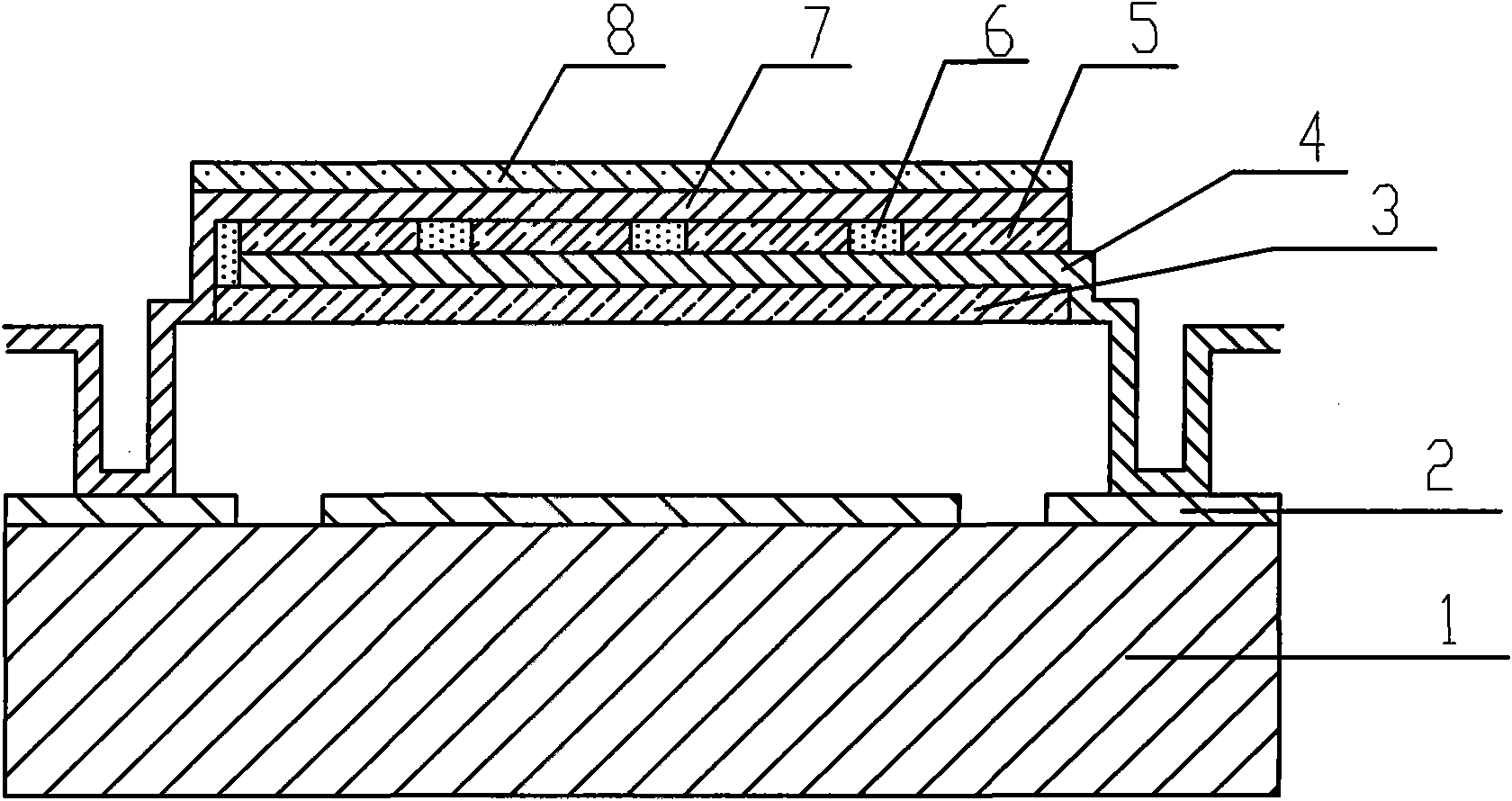

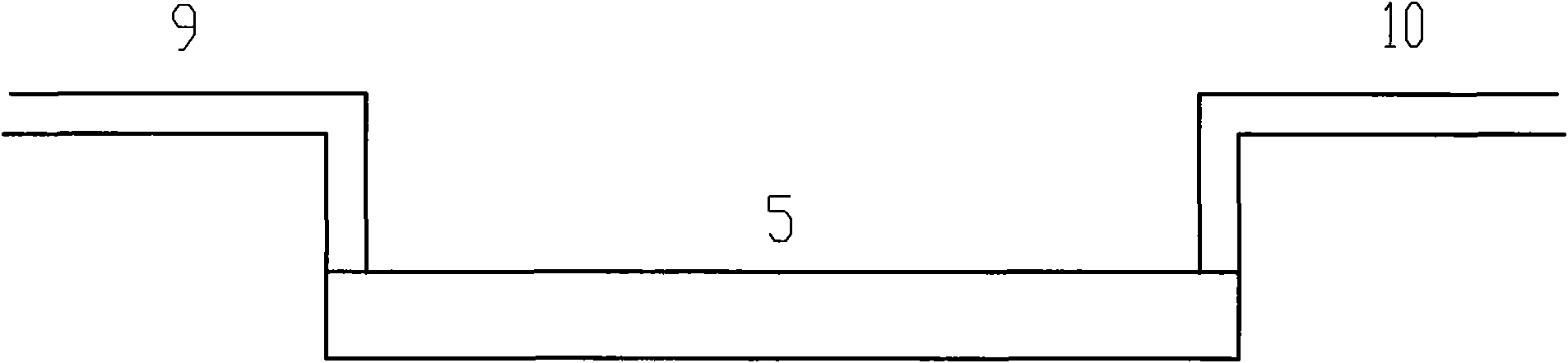

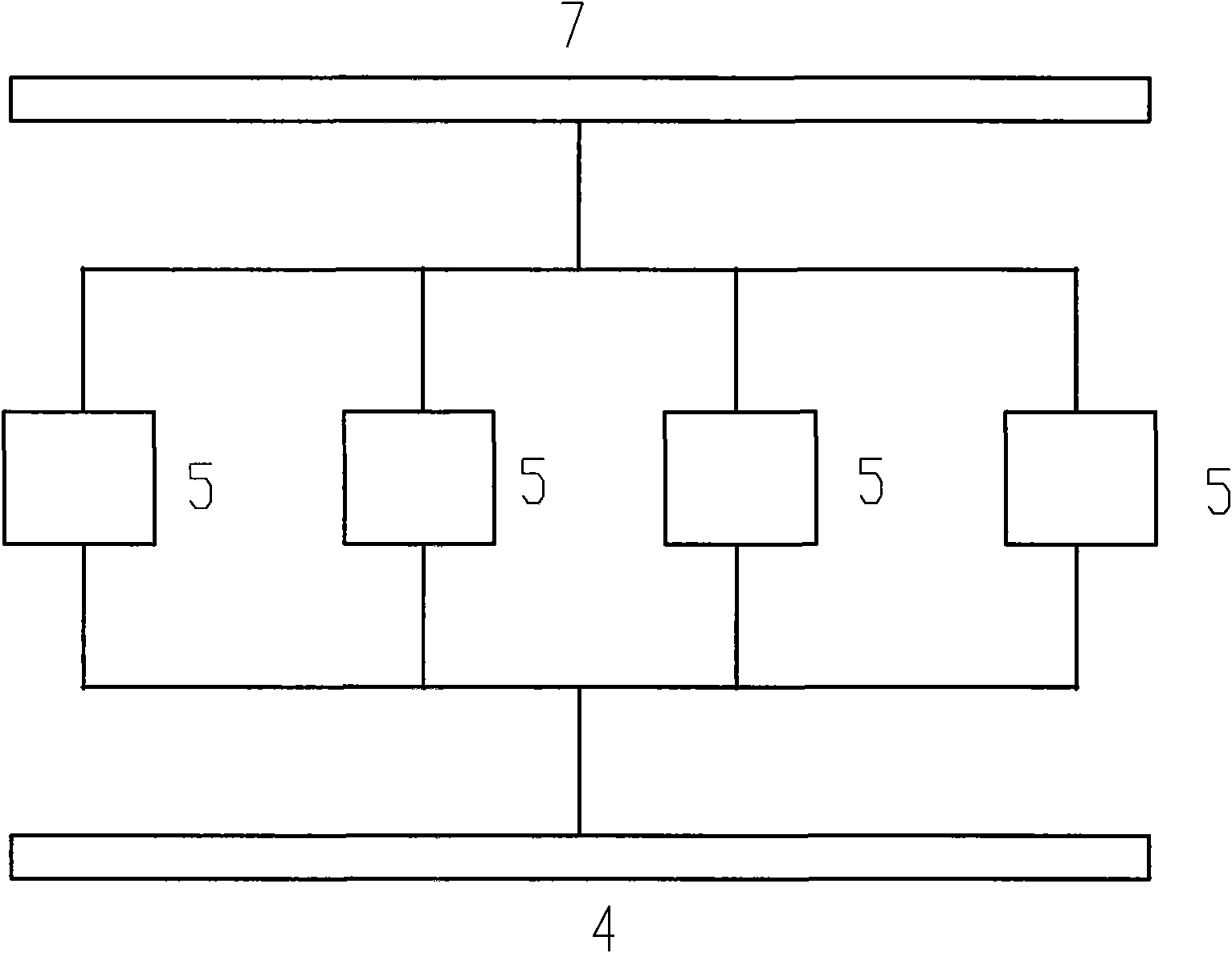

[0024] see figure 1 , the bolometer provided by the present invention, the device is a traditional bridge structure, including: a substrate 1, a support layer 3 above the substrate 1, a lower electrode 4 made on the support layer 3, and a lower electrode 4 prepared There is a thermistor 5, the thermistor 5 is covered with an upper electrode 7, and an absorption layer 8 is prepared on the upper electrode 7, wherein the substrate 1 and the support layer 3 are arranged in parallel with a gap, and the thermistor 5 is divided into independent unit groups It is arranged in parallel between the upper electrode 7 and the lower electrode 4 . The independent units of the thermistor 5 are evenly spaced. The space between each independent unit of the thermistor 5 is filled with silicon nitride material to form an isolation layer 6 . The material constituting the therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com