Flexible heating fabric system

A flexible fabric and fabric technology, applied in ohmic resistance heating, electric heating devices, electrical components, etc., can solve problems such as insufficient supply, and achieve the effects of simple structure, easy operation and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with embodiment and accompanying drawing thereof, but the present invention is not limited by embodiment:

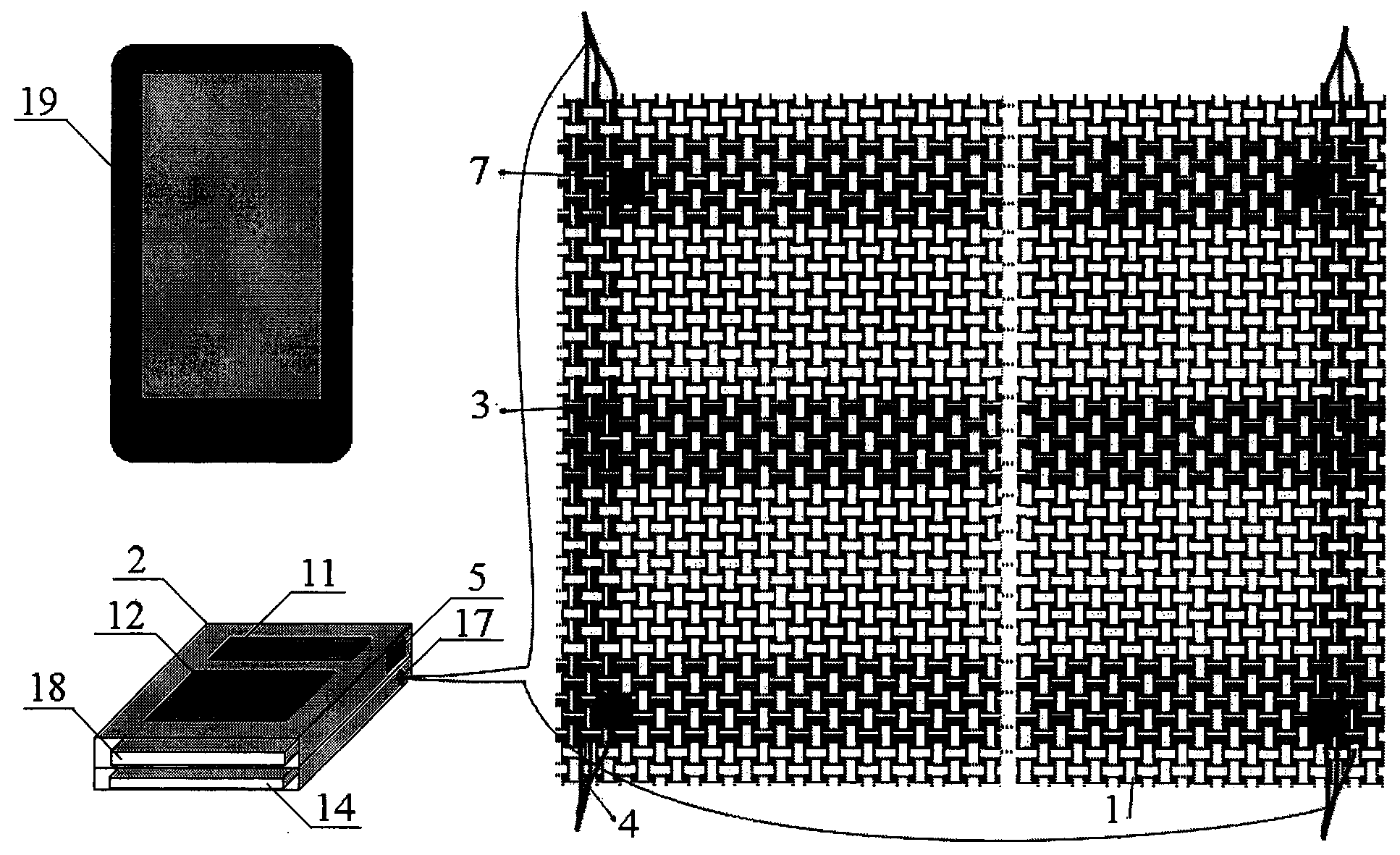

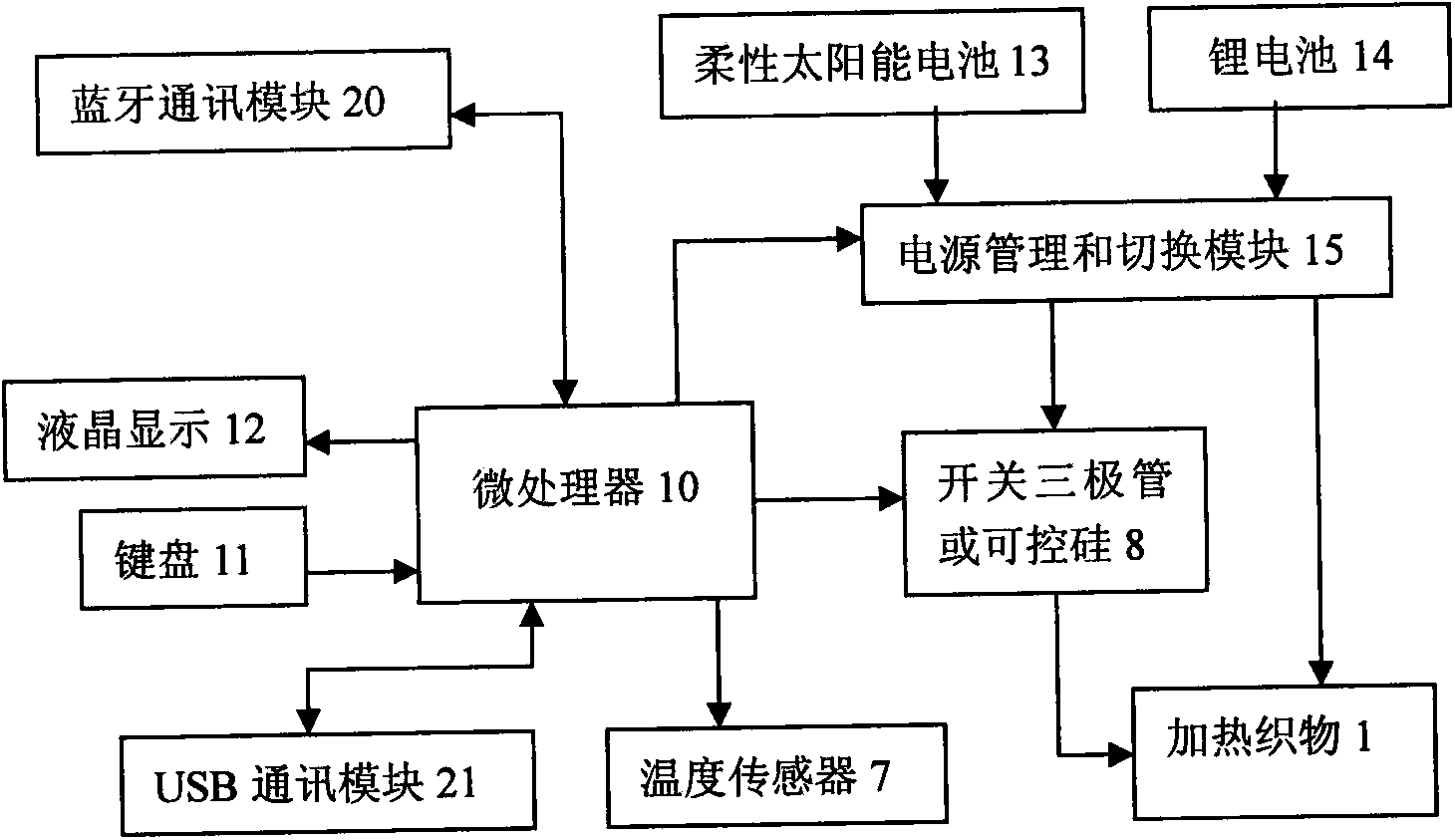

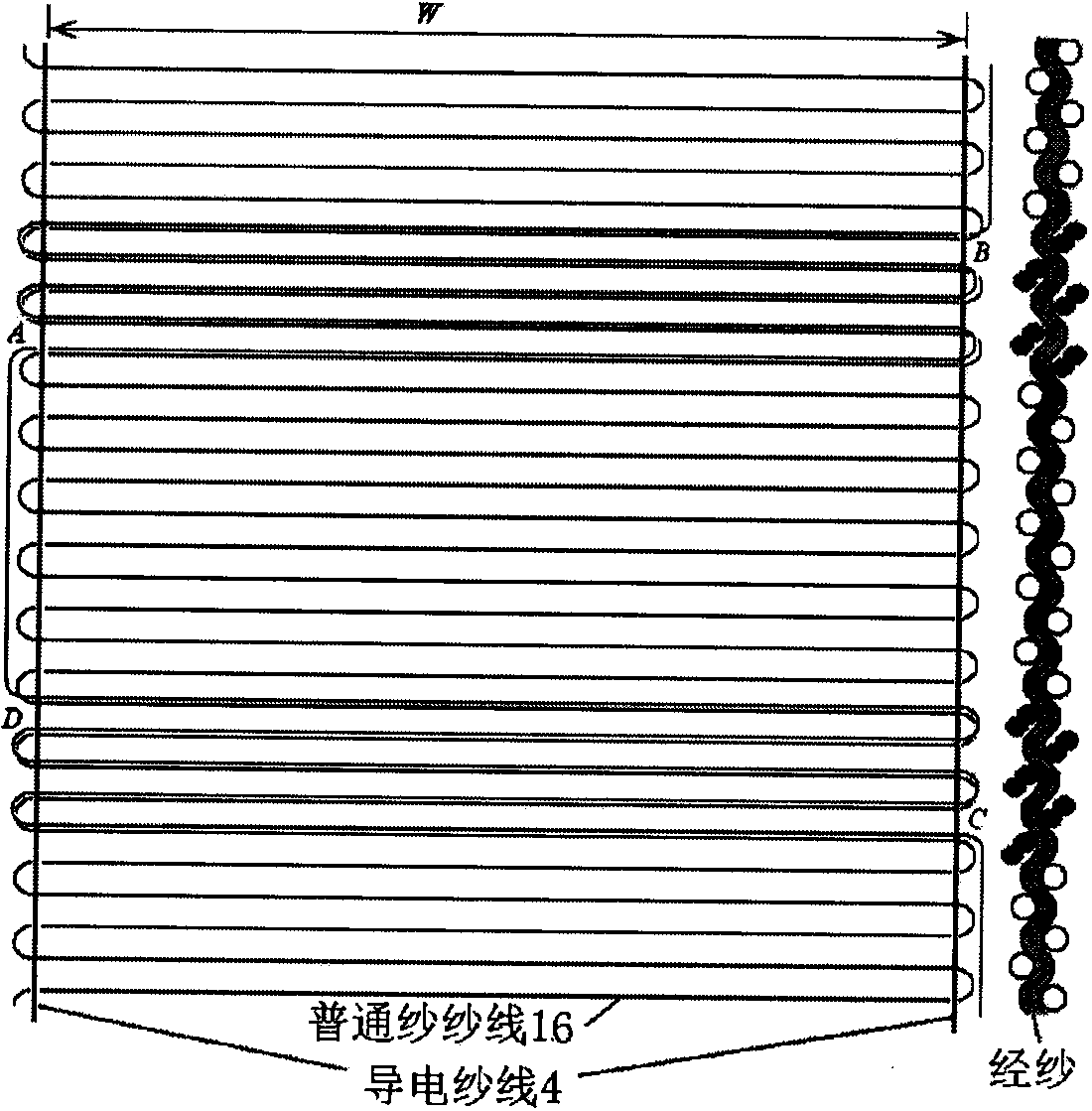

[0020] A kind of flexible heating fabric system of the present invention (see figure 1 —5), including two parts: flexible heating fabric and temperature measurement and control module. Wherein the flexible heating fabric 1 is made to have a heating function by weaving silver threads or silver-plated yarns 3 and 4 in the fabric. The heald diagram quantitatively controls the interweaving mode and spacing distance of the conductive yarns woven into the fabric, so as to achieve precise control of the resistance and power of the heating fabric. The flexible heating fabric 1 is as follows image 3 , 4 The two compilation methods shown are compiled, as follows Figure 4 The weaving methods shown are illustrative of specific examples.

[0021] The flexible fabric heating system includes a flexible heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com