Technology for producing stainless steel cable for automobile

A production process and stainless steel technology, applied in the field of stainless steel cables, can solve the problems of unsatisfactory cable travel efficiency and load efficiency, insufficient connection strength of core wire and core wire joint, affecting the appearance of the cable, etc., so as to reduce the processing cost. , The effect of improving the pull-off force and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

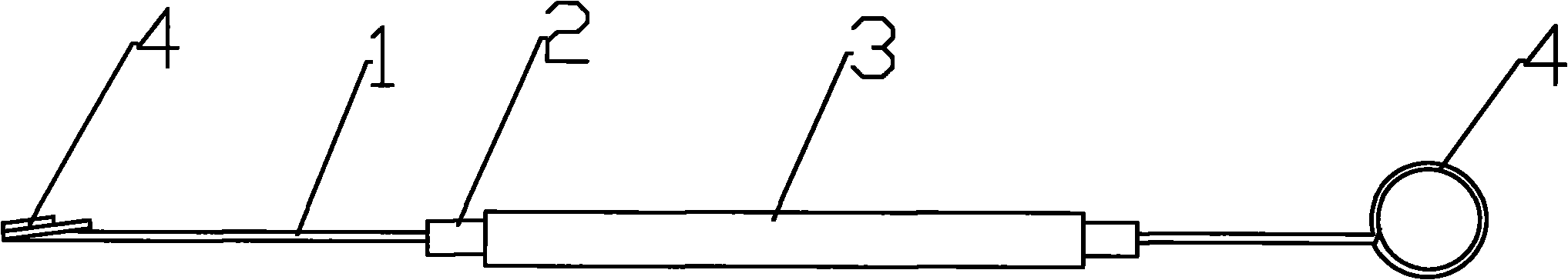

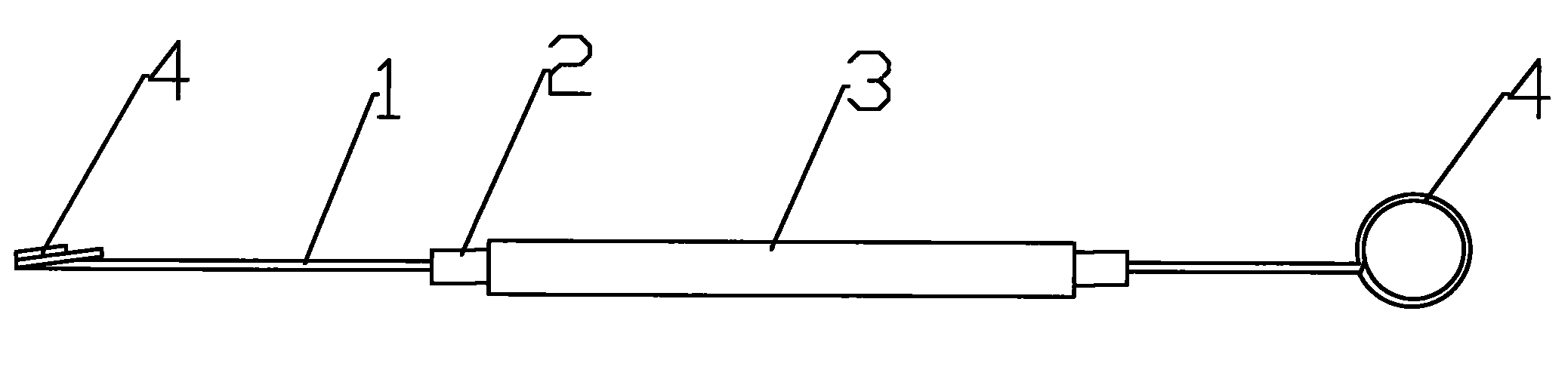

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] The production steps of the stainless steel cable production process for automobiles are as follows: firstly, the stainless steel wire is subjected to wire drawing treatment to produce a stainless steel core wire meeting the diameter requirement. When performing wire drawing, first tie the stainless steel wire to pass through the wire drawing die, put the wire drawing die in the mold box and pour chlorinated paraffin or lubricating powder into the mold box, and then use the traction chain to pull the stainless steel wire , Drawing with a wire drawing machine. There are multiple wire drawing dies, and the apertures of the multiple wire drawing dies gradually decrease along the direction of the wire drawing, and the aperture of the last wire drawing die is consistent with the required diameter of the core wire. The steel wire formed aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com