Environment-friendly and energy-saving multi-stage combination type high-performance fiber hyperploid heat drawing device

A high-performance fiber, environmental protection and energy-saving technology, applied in stretch spinning, complete sets of equipment for the production of artificial threads, textiles and papermaking, etc., can solve problems such as threading difficulties, increase manufacturing maintenance and use costs, and affect clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

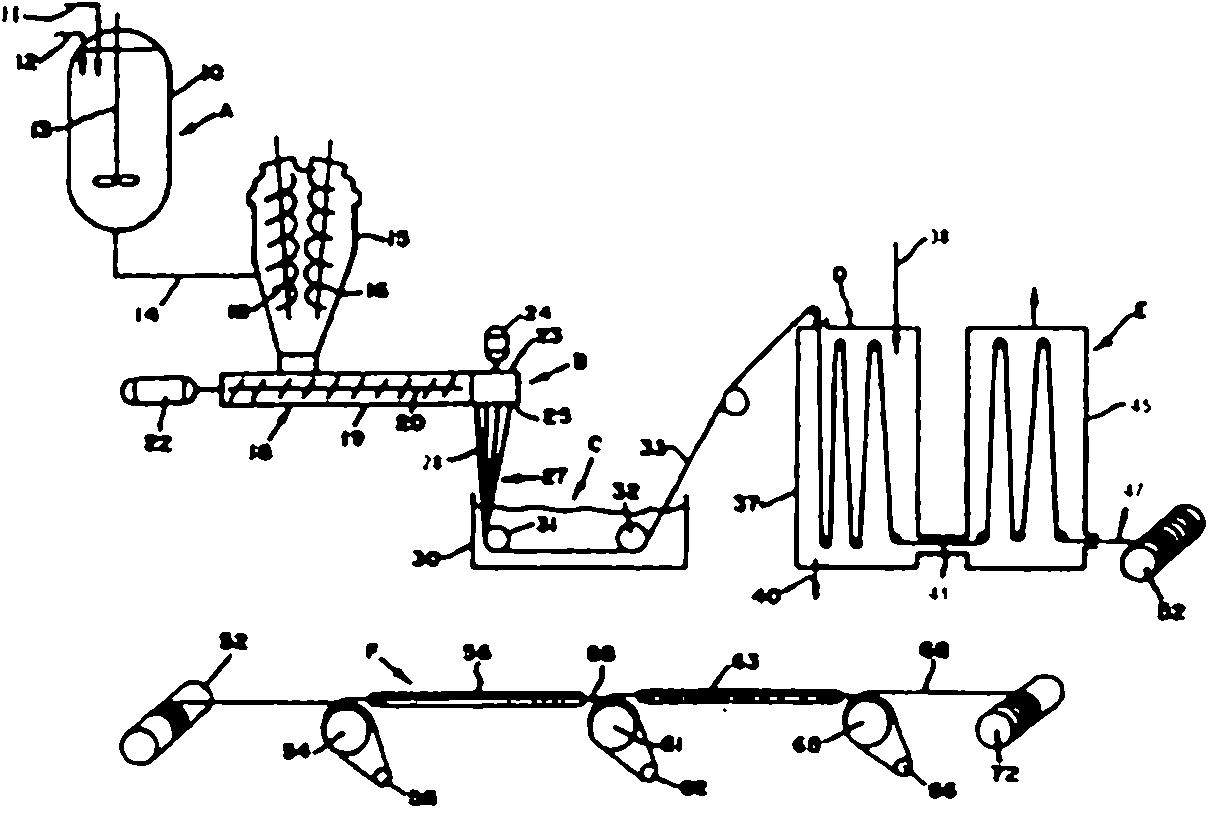

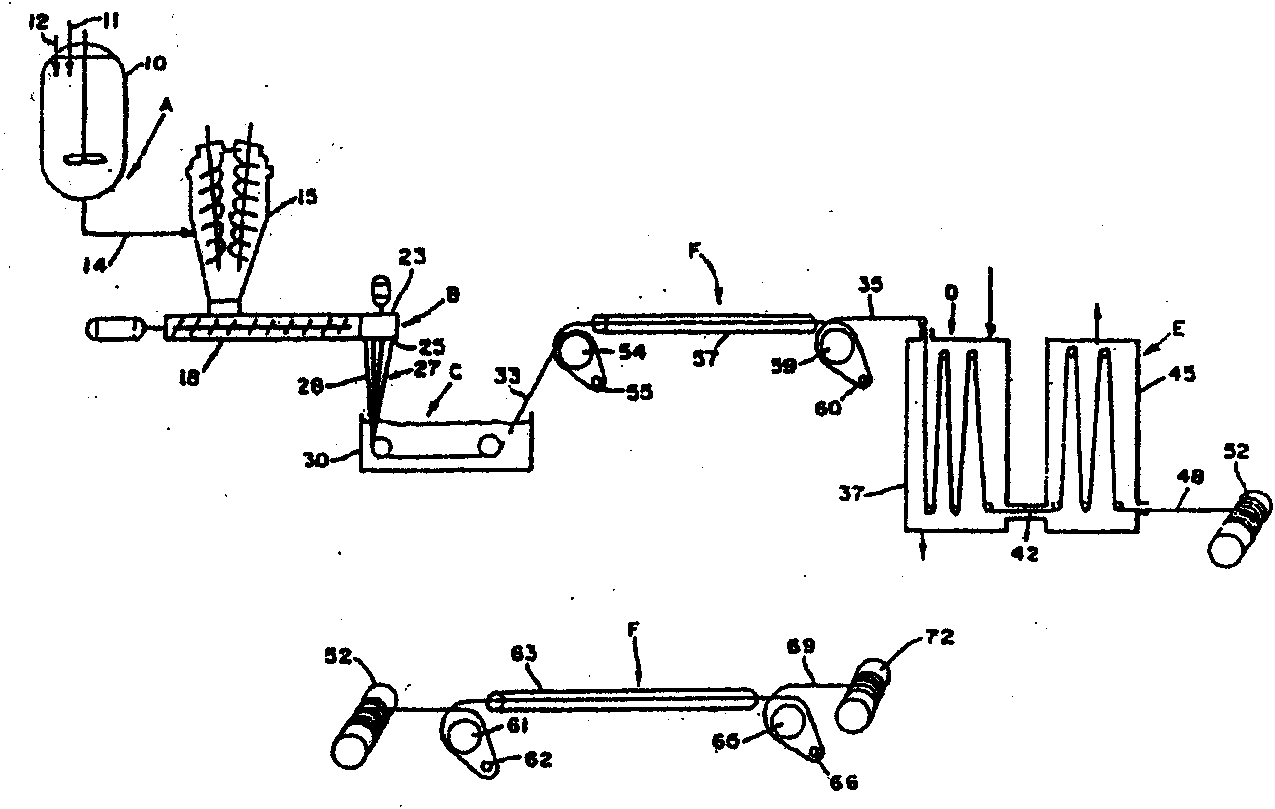

[0024] In this embodiment, there are nine stages of drafting in three hot boxes, and the total drafting ratio is higher than 60 times, but the present invention is not limited by this embodiment.

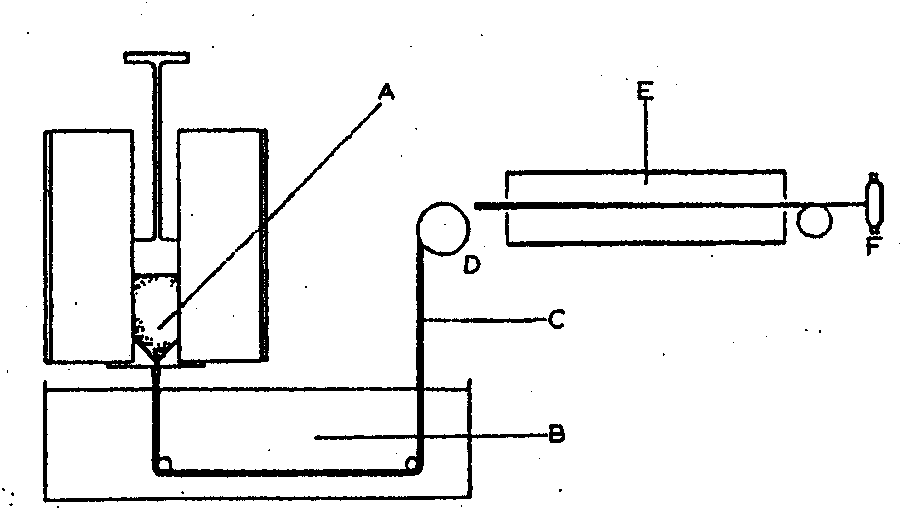

[0025] After the as-spun silk after being drawn by the nozzle (SSF) is extracted by the extraction device shown in Figure 120, after being dried at no higher than 70°C, it is passed through the first drawing heat oven 103 and the second heating oven 103 referred to in the present invention, respectively. The second drawing heat oven 103 and the third drawing heat oven 103 carry out super-heat drawing, and then pass through 122 as a winding device to produce HDPE fibers with a strength of 37g / d and a modulus of 1100g / d. The drawing temperature and multiple of each hot box are shown in the table below:

[0026] first hot box

[0027] first hot box

[0028] The drawing temperature of the first drawing heat oven and the drawing ratio of each level

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com