Multifunctional putty and preparation method thereof

A putty, multi-functional technology, applied in filling slurry and other directions, can solve problems such as difficult to adapt to the development requirements of automobiles, trains, machinery manufacturing and repair industry, long construction time, difficult to polish and other problems, and achieve excellent flexibility and adhesion, saving time for repairing, fine and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A kind of multifunctional atomic ash preparation method provided by the present invention, prepare raw material according to above-mentioned proportioning, comprise following specific steps:

[0040] The first step: Put the unsaturated polyester resin into the dispersion tank, add styrene, polymerization inhibitor, accelerator, thixotropic agent, anti-sedimentation agent at the same time and stir at 700 rpm for 8-10 minutes to obtain the first a dispersion;

[0041] Step 2: Add talcum powder to the first dispersion as mentioned above, stir at 1000-1250 rpm for 20-30 minutes, until the modified organic thixotropic agent is fully activated and dispersed evenly, and add the dispersed Wetting agent, stirred for 5-10 minutes to obtain the second dispersion;

[0042] Step 3: Add precipitated barium sulfate to the second dispersion as above, stir for 10-15 minutes at a speed of 1000-1100 rpm, wash the machine, and cool while stirring until the temperature of the ash body is l...

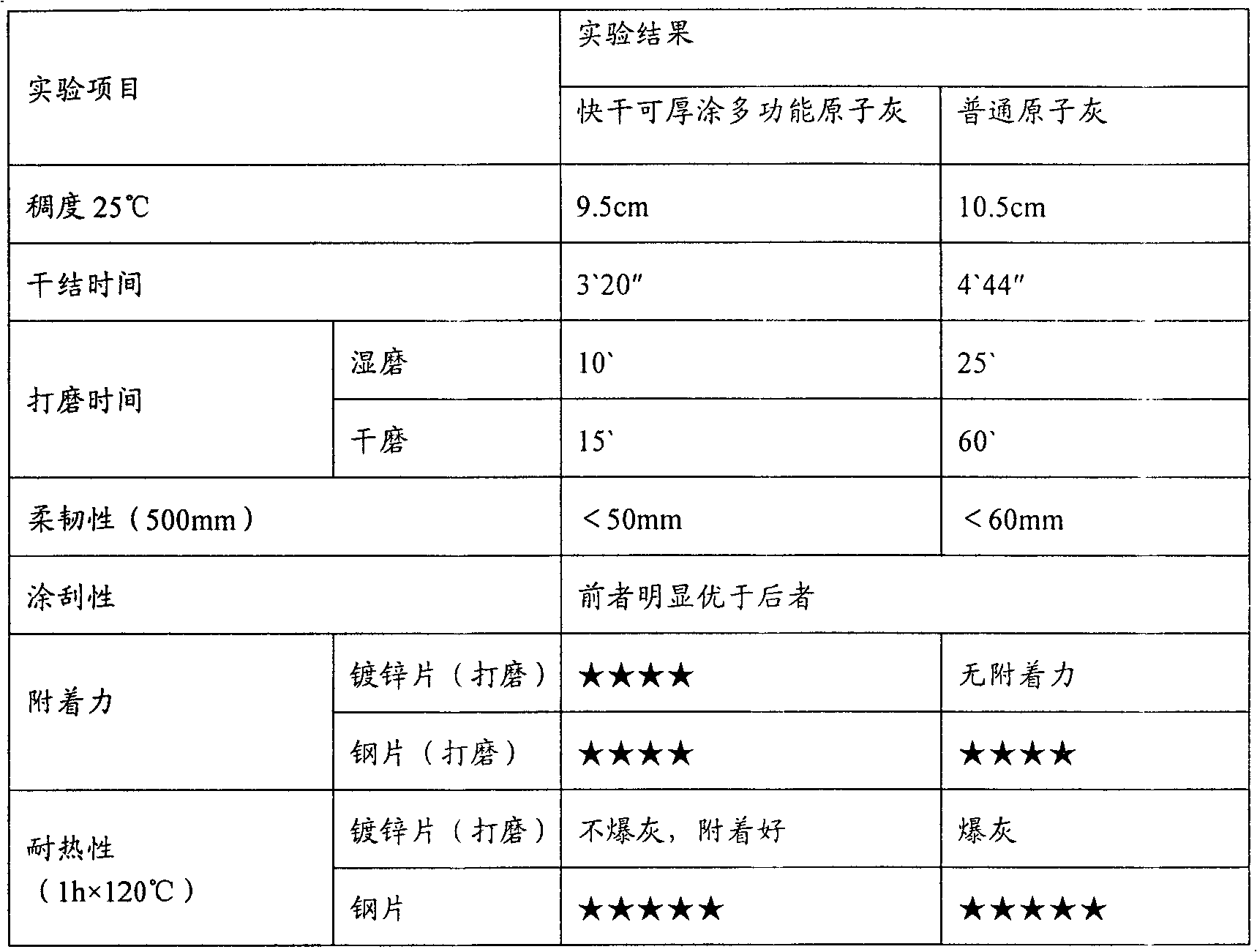

Embodiment 1

[0046] Embodiment 1, the composition and the weight percentage of main agent formula of this example are:

[0047] Unsaturated polyester resin: 33

Styrene: 4

Dispersion wetting agent: 0.5

Inhibitor: 0.01

Talc: 45

Accelerator: 0.03

Thixotropic agent: 0.5

Anti-sedimentation agent: 1

[0048] The curing agent is 50% benzoyl peroxide;

[0049] The specific preparation process steps of this example are, the first step: put the unsaturated polyester resin into the dispersion tank according to the formula amount in the above table, and add styrene, polymerization inhibitor, accelerator, thixotropic agent, anti-sedimentation agent at 700 Stirring for 8-10 minutes at a speed of rpm to obtain the first dispersion;

[0050] Step 2: Add talcum powder to the first dispersion as mentioned above, stir at 1000-1250 rpm for 20-30 minutes, until the modified organic thixotropic agent i...

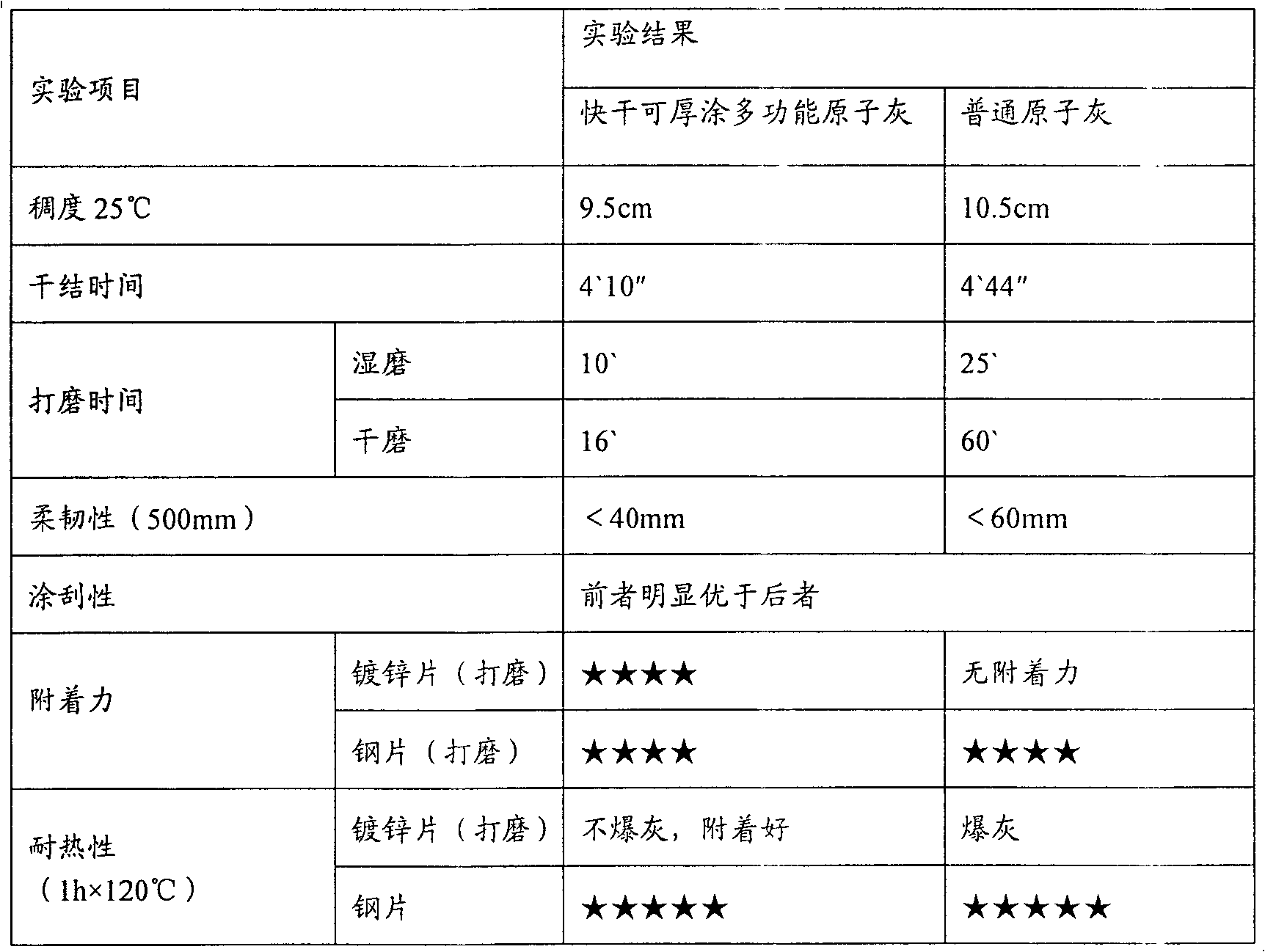

Embodiment 2

[0056] Embodiment 2, the composition and the weight percentage of main agent formula of this example are:

[0057] Unsaturated polyester resin: 35

Styrene: 3.5

Dispersion wetting agent: 0.5

Inhibitor: 0.01

Talc: 45

Accelerator: 0.03

Thixotropic agent: 0.5

Barium sulfate: 18.5

Anti-sedimentation agent: 1

[0058] The curing agent is 50% benzoyl peroxide;

[0059] The specific preparation process steps of this example are, the first step: put the unsaturated polyester resin into the dispersion tank according to the formula amount in the above table, and add styrene, polymerization inhibitor, accelerator, thixotropic agent, anti-sedimentation agent at 700 Stirring for 8-10 minutes at a speed of rpm to obtain the first dispersion;

[0060] Step 2: Add talcum powder to the first dispersion as mentioned above, stir at 1000-1250 rpm for 20-30 minutes, until the modified organic thixotropic age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com