Method for preparing formic acid through hydrothermal reduction of CO2 by carbohydrate biomass

A carbohydrate and biomass technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., to achieve the effects of convenient operation, no secondary pollution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

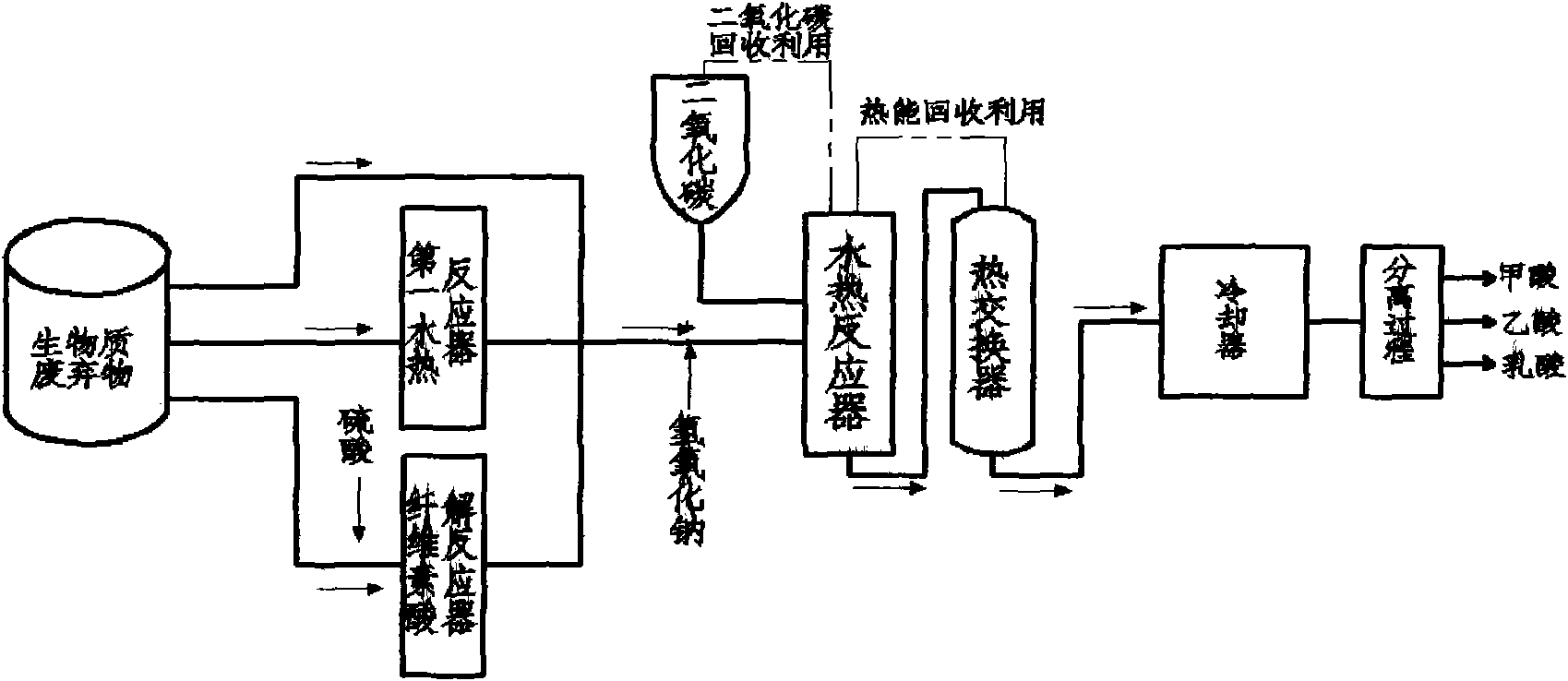

[0023] attached figure 1 It is a schematic process flow diagram of the present invention. The raw material biomass in the hydrothermal reaction process of the present invention is divided into three forms:

[0024] 1. Feed the crushed biomass directly into the reactor while feeding CO 2 , the cellulose contained in biomass directly reduces CO under hydrothermal conditions 2 ;

[0025] Second, the crushed biomass is converted into glucose, hexyl alcohol, etc. through hydrothermal reaction, and then these glucose and hexyl alcohol enter the reactor and are combined with CO 2 Mixed, CO reduction under hydrothermal conditions 2 ;

[0026] 3. The crushed biomass is converted into glucose, hexyl alcohol, etc. through conventional acidolysis reaction, and these glucose and hexyl alcohol enter the reactor to be mixed with CO 2 Mixed, CO reduction under hydrothermal conditions 2 .

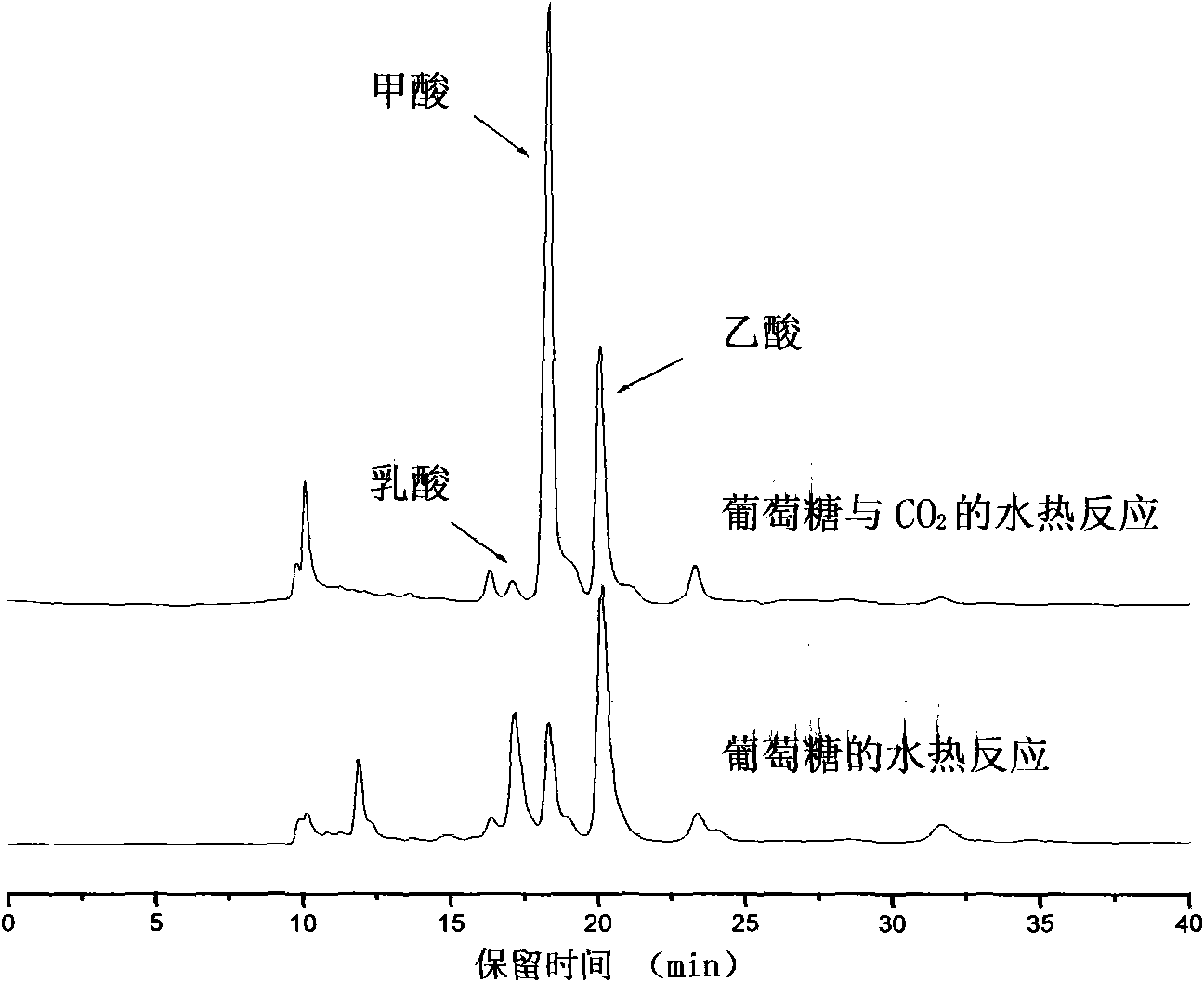

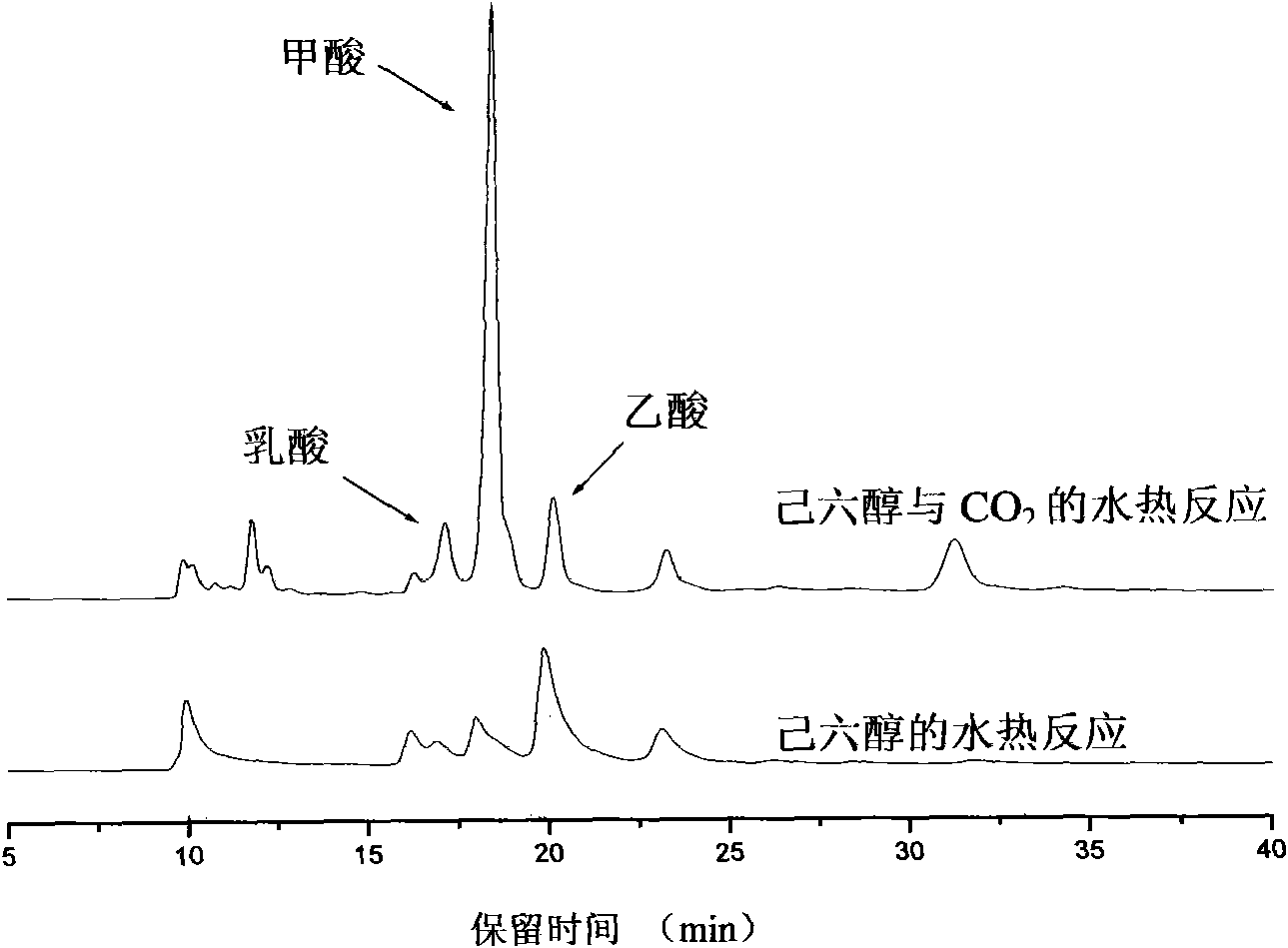

[0027] Small-scale experiments use cellulose (polysaccharide) and the most basic monosaccharides...

Embodiment 2

[0032] CO 2 Use of CO emitted by coal chemical enterprises 2 , CO in coal-to-oil and coal-to-methanol industries 2 The emissions were 9.2 tons of CO 2 / ton of synthetic oil, 3.8 tons of CO 2 / ton of methanol, and CO in the exhaust gas 2 The purity is as high as 80-90%. Coal chemical enterprises select appropriate hydrothermal reactors according to actual needs, including CO 2 The exhaust gas can be directly passed into the hydrothermal reactor, other components in the exhaust gas such as SO x , NO x etc. had no effect on the reaction.

[0033] There are more than 600 million tons of crop straws in my country every year. At present, direct combustion is the most important way to use straws. About 140 million tons of straws are directly used for burning every year, which not only causes serious ecological and environmental problems, but also greatly consumes resources. waste. Straw contains about 30% cellulose, and the use of straw to reduce CO emissions from coal chem...

Embodiment 3

[0036] CO 2 The source is the exhaust from coal-fired power plants. Currently, China's power sector emits 2.7 billion tons of CO2 per year 2 It ranks second in the world after the United States. my country is the largest rice producer in the world, and the sown area of rice accounts for about 23% of the whole world. The chaff contains about 23.16% cellulose, and the chaff is crushed to a particle size of 1-10 mm, then dried, and directly enters the reactor. Use a carbon content analyzer to measure the carbon content in the chaff, according to the carbon content in the chaff: CO in the exhaust gas 2 : NaOH=3: (5~20): (5~20) mol ratio is added in the reactor, the carbon concentration of chaff is kept on 1.2~2.4mol / l, the addition of water is by filling rate 30%~ 60% multiplied by the reactor volume. CO emissions from coal-fired power plants 2 The collection is passed into the hydrothermal reactor for treatment, and the waste heat of the power plant can provide the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com