Preparation method of calcium oxide expansion agents

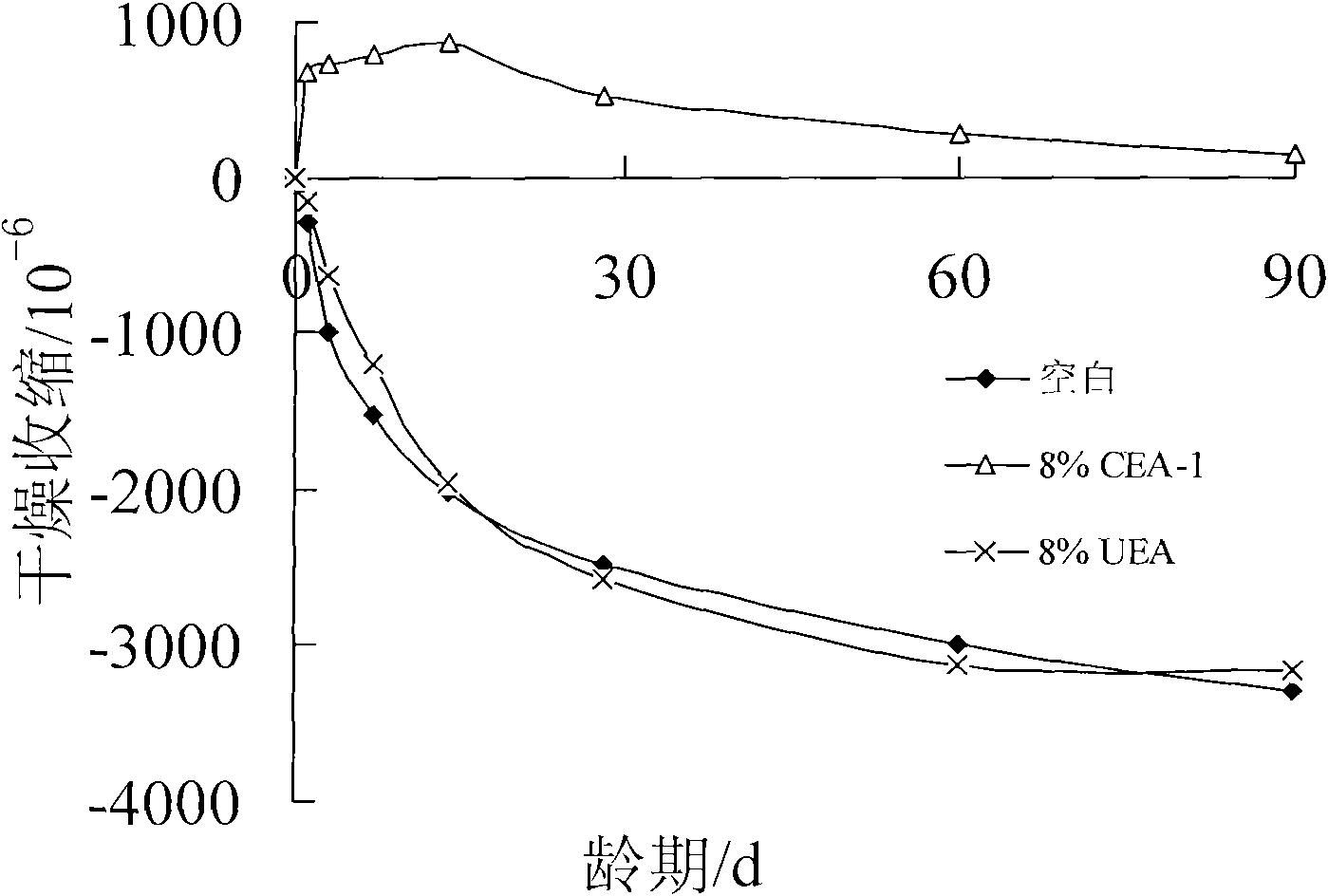

A calcium oxide and expansion agent technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of destroying cement concrete structure, long duration of hydration reaction, limited shrinkage compensation effect, etc., to achieve High expansion efficiency, reduced risk of drying shrinkage cracking, fast expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Limestone with a mass ratio of 90:10 is mixed with a composite mineralizer and ground together by a ball mill to a fineness of 200m 2 / kg of raw meal powder, in which the composite mineralizer is composed of 55% gypsum and 45% copper slag. The ground raw meal powder was calcined at 1200°C, and kept at this temperature for 120 minutes (that is, the calcination time at 1200°C was 120 minutes). After the heat preservation was completed, the fired sample was taken out and quenched in air to obtain Calcium expanded clinker. Grind the prepared calcium oxide expanded clinker and dispersive carrier material together according to the ratio until the specific surface area is 300m 2 / kg, the mixing mass ratio is 80:20, and the dispersive carrier material is porous zeolite. After homogenization, it is sealed and packaged to obtain a calcium oxide expansion agent CEA-1 of the present invention that can effectively expand cement concrete in a dry environment. The product meets the ...

Embodiment 2

[0022] Limestone with a mass ratio of 90:10 is mixed with a composite mineralizer and ground together by a ball mill to a fineness of 200m 2 / kg of raw meal powder, in which the composite mineralizer is composed of 50% gypsum and 50% copper slag. The ground raw meal powder was calcined at 1250°C, and kept at this temperature for 80 minutes. After the heat preservation was completed, the fired sample was immediately taken out and quenched in the air to obtain calcium oxide expanded clinker. Grind the prepared calcium oxide expanded clinker and the dispersive carrier material together according to the ratio to a fineness of specific surface area of 250m 2 / kg, the mixing mass ratio is 77:23, and the dispersive carrier material is high-quality Class I fly ash. After homogenization, it is sealed and packaged to obtain a calcium oxide expansion agent CEA-2 of the present invention that can effectively expand cement concrete in a dry environment. The product meets the requirement...

Embodiment 3

[0024] Limestone with a mass ratio of 92:8 is mixed with a composite mineralizer and then ground together by a ball mill to a fineness of 200m 2 / kg of raw meal powder, in which the composite mineralizer is composed of 65% gypsum and 35% copper slag. The ground raw meal powder was calcined at 1300°C, and kept at this temperature for 50 minutes. After the heat preservation was completed, the fired sample was immediately taken out and quenched in the air to obtain calcium oxide expanded clinker. Grind the prepared calcium oxide expanded clinker and dispersive carrier material together according to the ratio until the specific surface area is 300m 2 / kg, the mixing mass ratio is 85:15, and the dispersive carrier material is composed of 60% porous zeolite and 40% high-quality Class I fly ash. After homogenization, it is sealed and packaged to obtain a calcium oxide expansion agent CEA-3 of the present invention that can effectively expand cement concrete in a dry environment. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com