Method for preparing infrared transmitting germanate/gallate optical glass

A technology of optical glass and gallate, applied in glass manufacturing equipment, glass molding, glass furnace equipment, etc., can solve the problems of chloride volatilization, environmental pollution, unsuitable for industrial production, etc., to improve activity and accelerate chemical Response, the effect of reducing the amount of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 25GeO made of glass 2 +30Ga 2 o 3 +25BaO+5Al 2 o 3 +15BaF 2 A total of 2kg of glass raw materials, various powders are placed in a ball mill and fully mixed.

[0027] a) Pre-dewatering of raw materials: drying the powdered raw materials at 300°C for 24 hours. After the raw materials were transferred to platinum crucibles, they were placed in an electric furnace at a temperature of 300°C. Oxygen and CCl are introduced into the electric furnace 4 Mixed gas, keep warm for 10 hours, where CCl 4 The flow ratio of gas and oxygen is controlled to be 10:100;

[0028] b) Melt the powder raw material at a heating rate of 300°C / hour to 1350°C, and change to an inert gas protection when the temperature rises to close to 600°C, and the inert gas is nitrogen;

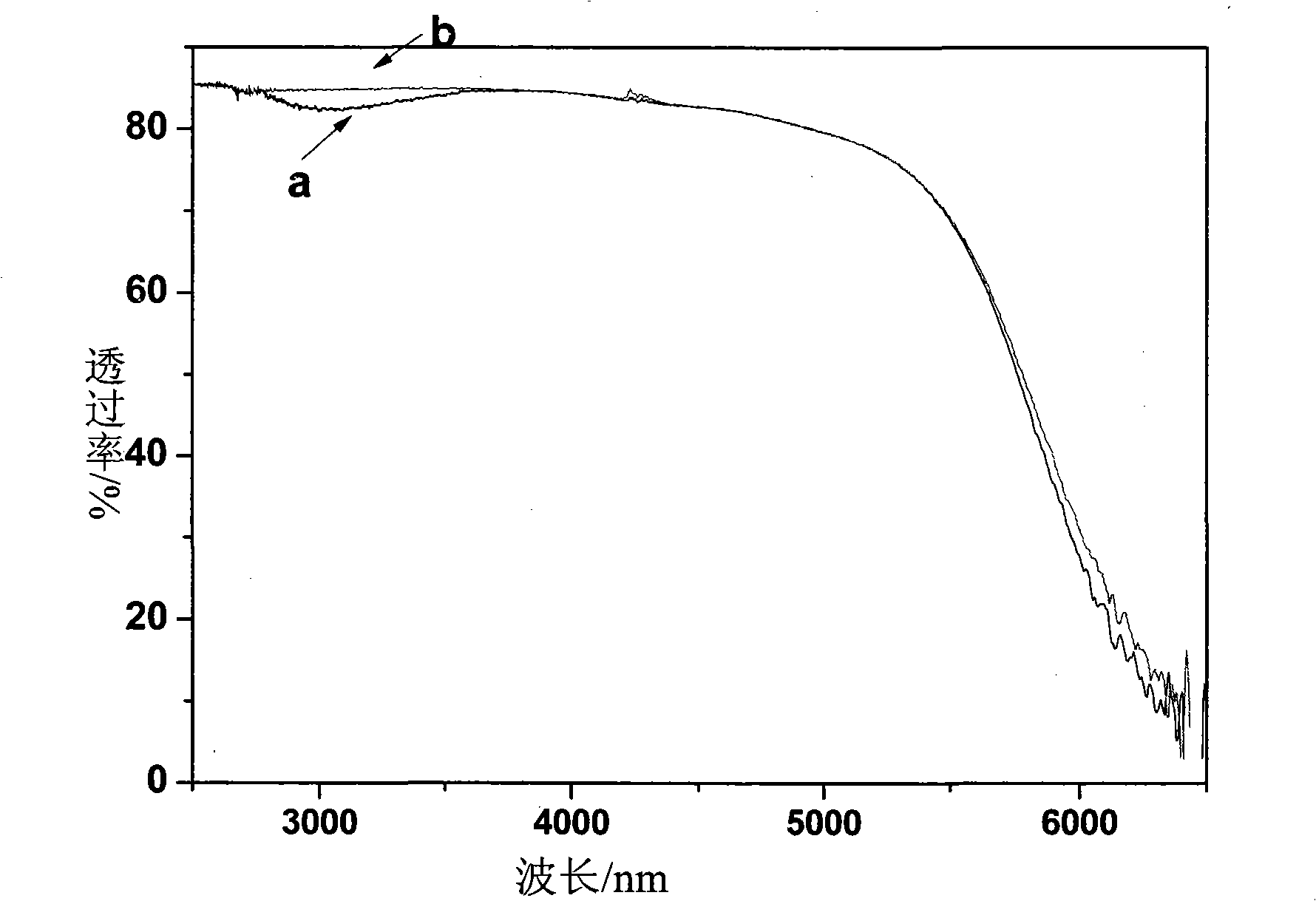

[0029] c) After putting a stirring paddle into the glass liquid and stirring for 6 hours, the protective gas was changed to 35:100 O 2 : Mixed gas of Ar, maintain the aeration protection state while stirring for 1 ho...

Embodiment 2、3、4、5、6 and 7

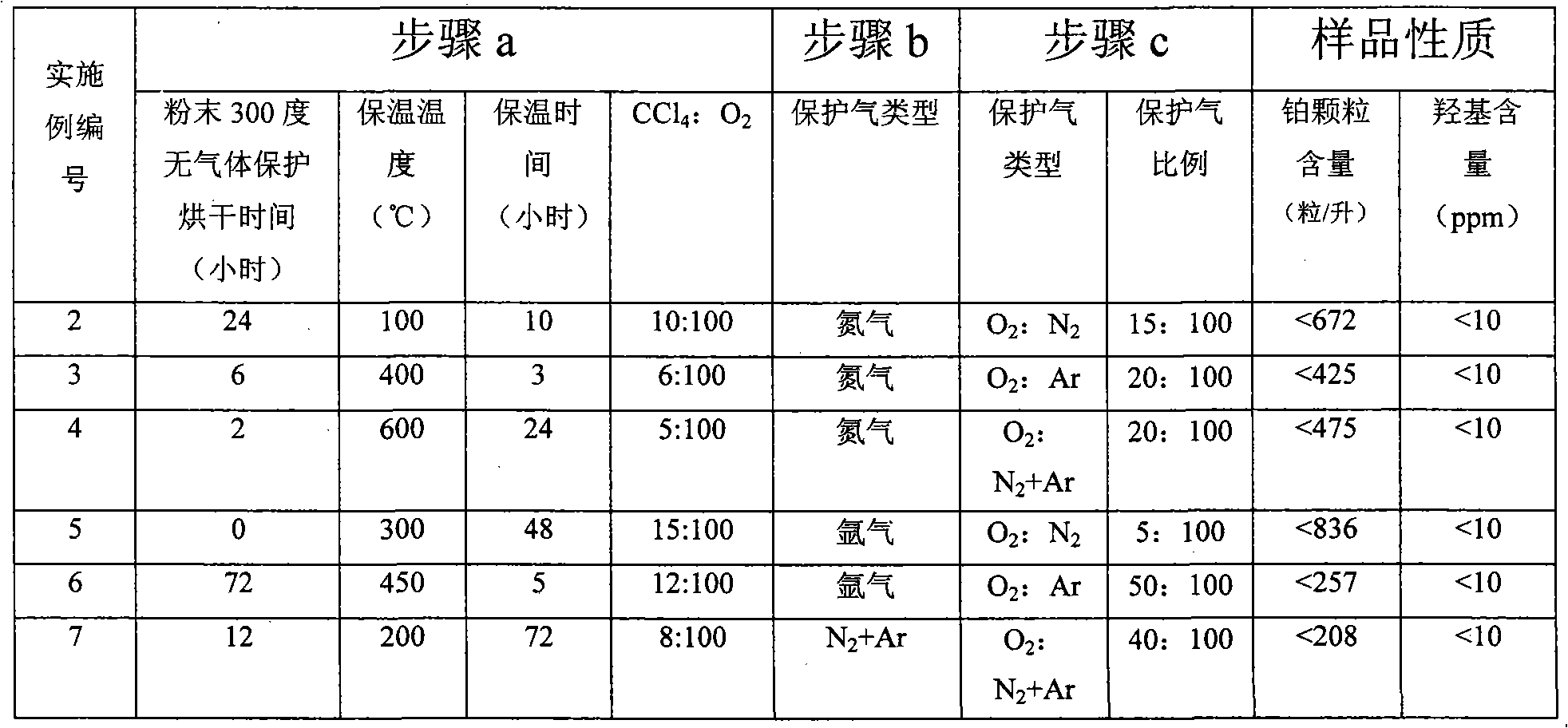

[0033] Embodiments 2, 3, 4, 5, 6 and 7: using the same glass composition as in Embodiment 1, similar process, the difference of each step is shown in the following table 1; in addition, in step c, maintain the state of stirring and aeration protection at the same time After 3 hours, the platinum particle content and hydroxyl content of the obtained sample are also marked in the corresponding positions in the table.

Embodiment 8

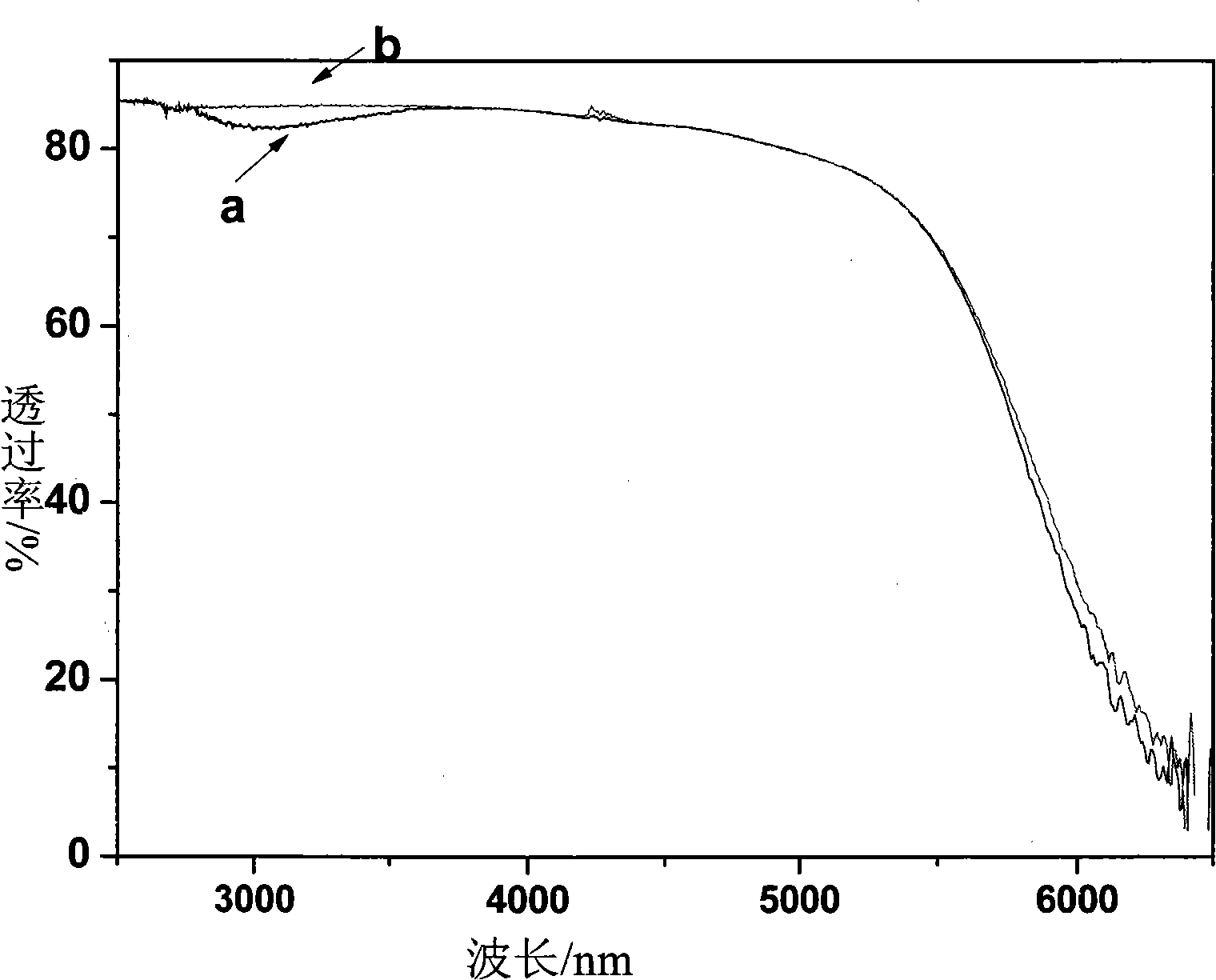

[0035] The composition of the glass is the same as that of Example 7, and the process is similar, the difference is that the state of stirring and aeration protection is maintained for 2 hours to obtain a high-quality infrared glass with a platinum particle concentration of 600 / L and a moisture content of less than 10 ppm in the infrared glass, which meets the requirements of general infrared optics. glass requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com