Hot fogging concentrate containing propiconazole and chlorpyrifos and preparation method thereof

A technology of chlorpyrifos and propiconazole, applied in the field of pesticides for the control of plant diseases and insect pests, can solve the problems of not being able to use low-stalk plants in relatively open spaces, increasing labor intensity and working time, and not being able to withstand rain erosion, so as to achieve easy access to the target Effects in the body, saving labor costs for pesticide application, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

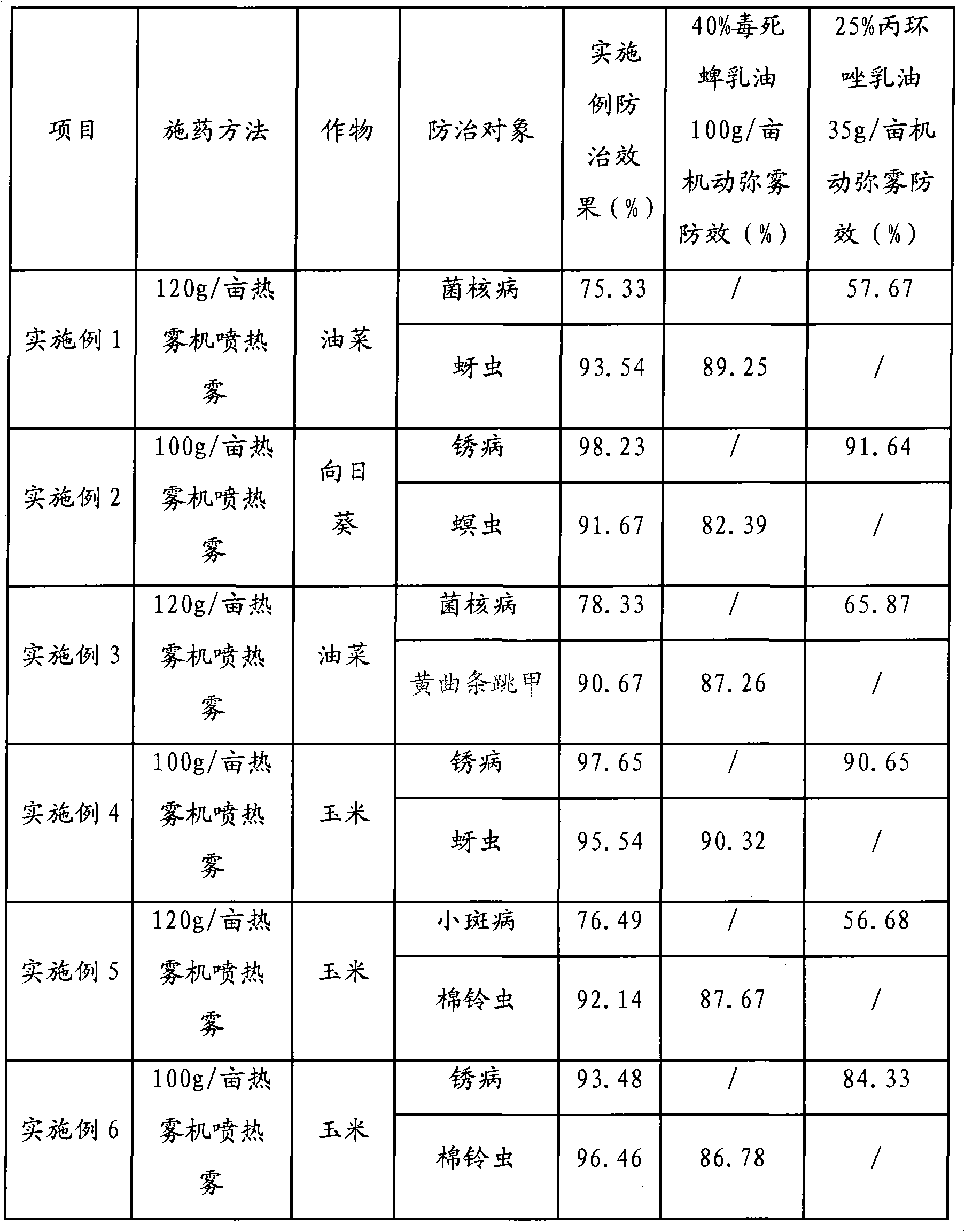

Examples

Embodiment 1

[0027] Raw material formula: by mass percentage

[0028] The active ingredient chlorpyrifos 26%;

[0029] Active component propiconazole 4%;

[0030] Solvent aromatics No. 2 20%;

[0031] Surfactant EO-PO block copolymer 5%;

[0032] Thickener polyvinyl alcohol 2%;

[0033] Antifreeze and thermal fog density regulator urea 5%

[0034] Antifoaming agent polydimethylsiloxane 0.1%.

[0035] The rest is water.

[0036] The urea in the composition has the functions of an antifreeze agent and a thermal fog density regulator.

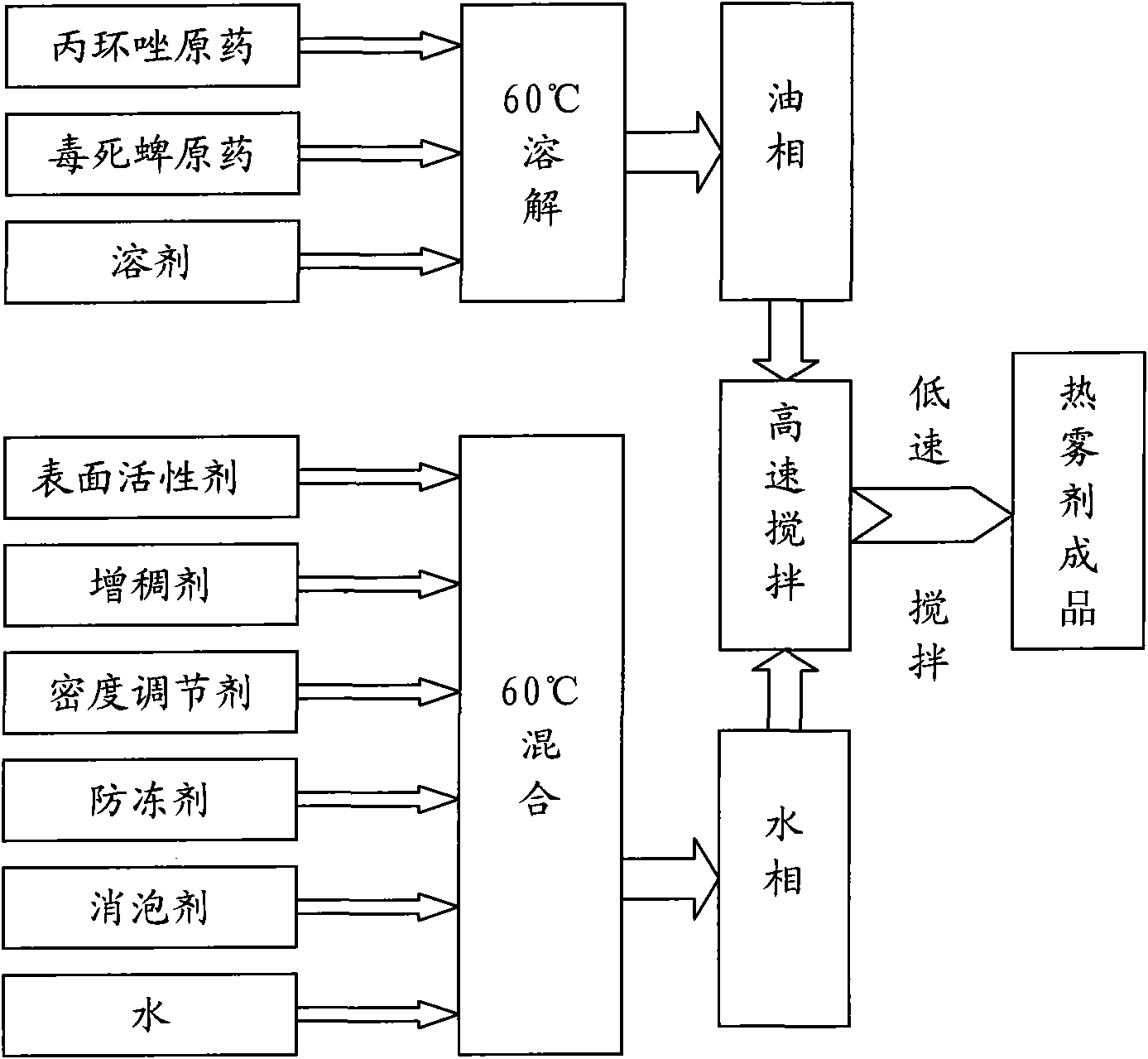

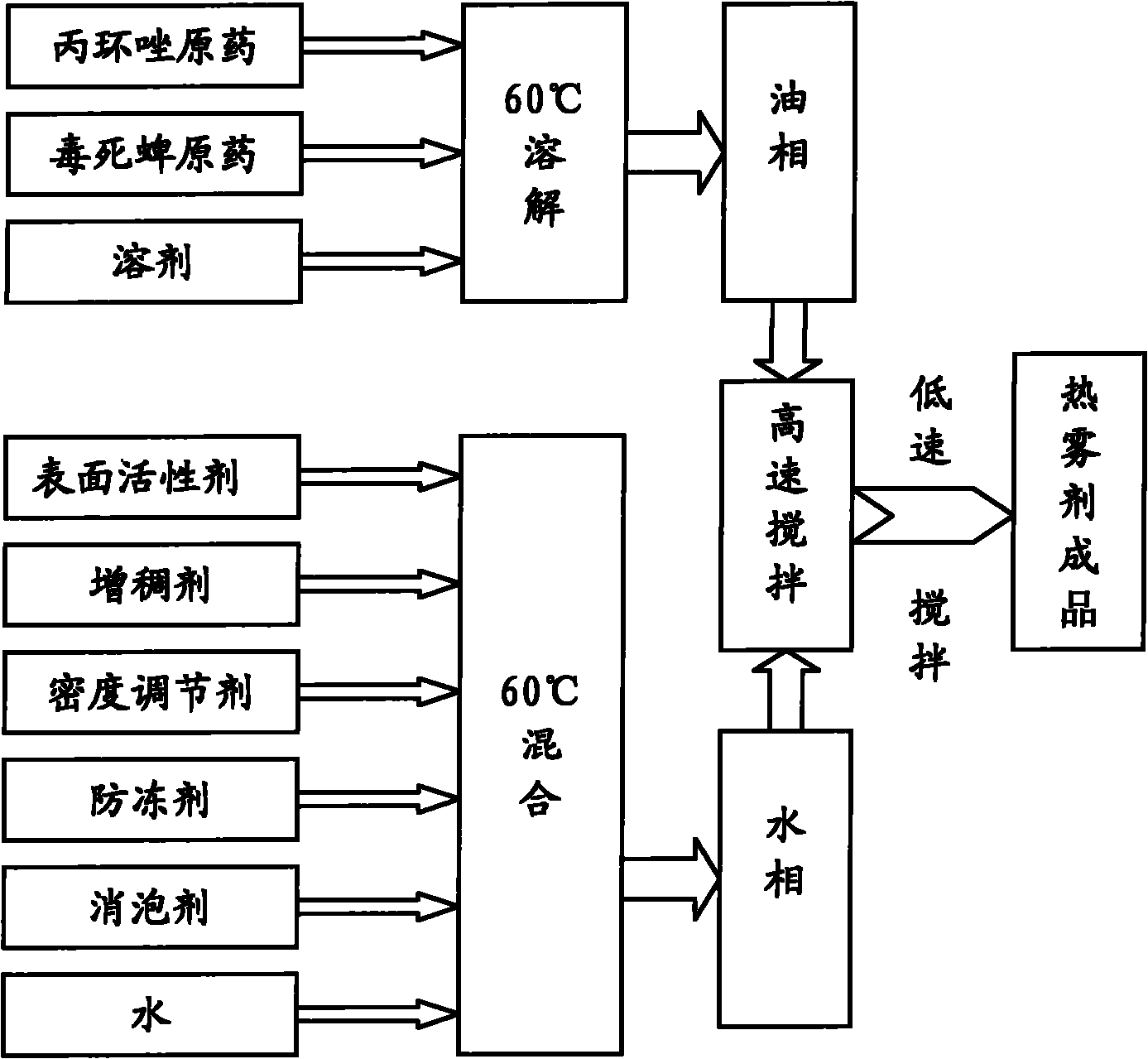

[0037] Preparation:

[0038] (1) Preparation of the oil phase: Add the active components (chlorpyrifos, propiconazole) and solvent (arene No. 2) into a preparation kettle with a temperature of 60°C, and dissolve into an oil phase under stirring for later use;

[0039] (2) Preparation of water phase: combine surfactant (EO-PO block copolymer), thickener (polyvinyl alcohol), antifreeze (urea), thermal fog density regulator (urea), defoamer (Polydimethylsiloxane) and water are a...

Embodiment 2

[0042] Active ingredient chlorpyrifos 30%;

[0043] Active component propiconazole 5%;

[0044] Solvent Aromatic No. 2 15%;

[0045] Solvent Aromatic No. 3 7%

[0046] Surfactant EO-PO block copolymer 5%;

[0047] Thickener xanthan gum 0.15%;

[0048] Antifreeze and thermal fog density regulator urea 5%

[0049] Antifoaming agent polydimethylsiloxane 0.1%

[0050] Water 32.75%.

[0051] The urea in the composition has the functions of an antifreeze agent and a thermal fog density regulator.

[0052] The preparation method is the same as in Example 1.

Embodiment 3

[0054] Raw material formula: by mass percentage

[0055] The active ingredient chlorpyrifos 26%;

[0056] Active component propiconazole 4%;

[0057] Solvent aromatics No. 2 20%;

[0058] Surfactant EO-PO block copolymer 2%;

[0059] Surfactant Nongru 500 1%,

[0060] Surfactant OP-10 2%

[0061] Thickener polyvinyl alcohol 2%;

[0062] Antifreeze and thermal fog density regulator urea 5%

[0063] Antifoaming agent polydimethylsiloxane 0.1%

[0064] Water 37.9%.

[0065] The urea in the composition has the functions of an antifreeze agent and a thermal fog density regulator.

[0066] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com