Full transparent AlGaN/GaN high electron mobility transistor and manufacturing method thereof

A technology with high electron mobility and fabrication method, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problem that the breakdown field strength and material mobility are not as good as GaN materials, limit the application of AlGaN/GaN HEMT, and cannot achieve full Transparent electronic device application and other issues, to achieve the effect of improving electrical conductivity and improving anti-radiation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, the making of device of the present invention, comprises the following steps:

[0032] Step 1. Epitaxial material growth.

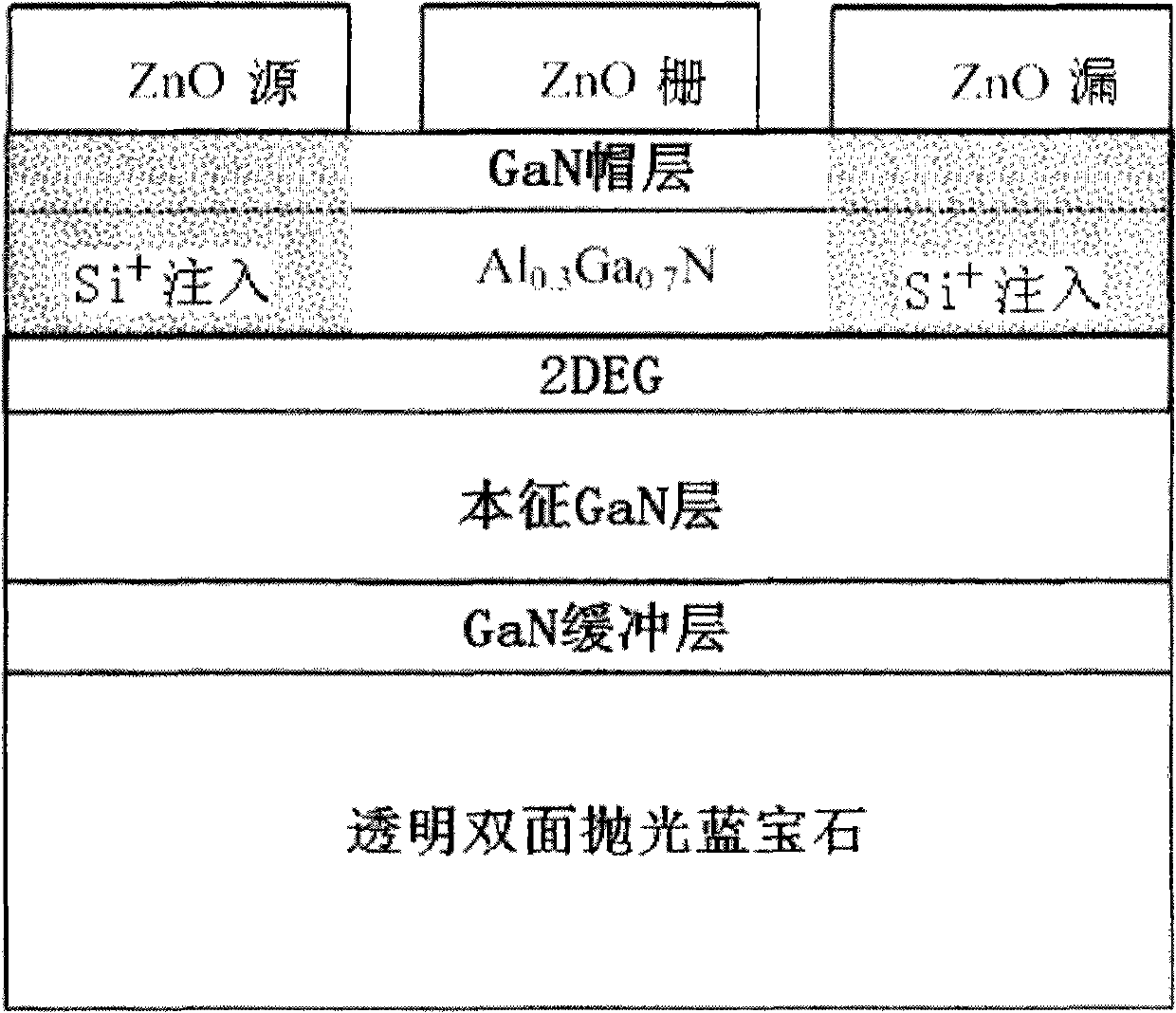

[0033] refer to figure 1 and figure 2 , the specific implementation of this step is as follows:

[0034] (101) On the double-sided polished sapphire substrate, grow a GaN buffer layer by MOCVD process;

[0035] (102) growing an intrinsic GaN layer on the GaN buffer layer;

[0036] (103) On the intrinsic GaN layer, a 20nm thick Al 0.3 Ga 0.7 N layer, intrinsic GaN layer and Al 0.3 Ga 0.7 2DEG is formed between N layers;

[0037] (104) in Al 0.3 Ga 0.7 On the N layer, a 2nm thick GaN cap layer is grown.

[0038] Step 2. Fabrication of source and drain electrodes.

[0039] refer to figure 1 and image 3 , the specific implementation of this step is as follows:

[0040] (201) Using PECVD equipment to protect the surface of the device with SiN coverage;

[0041] First, put the sample in acetone for 2 minutes, then in ethan...

Embodiment 2

[0059] Embodiment 2, the making of device of the present invention, comprises the following steps:

[0060] Step 1. Epitaxial material growth.

[0061] refer to figure 1 and figure 2 , the specific implementation of this step is as follows:

[0062] (101) On the double-sided polished sapphire substrate, grow a GaN buffer layer by MOCVD process;

[0063] (102) growing an intrinsic GaN layer on the GaN buffer layer;

[0064] (103) On the intrinsic GaN layer, a 20nm thick Al 0.3 Ga 0.7 N layer, intrinsic GaN layer and Al 0.3 Ga 0.7 2DEG is formed between N layers;

[0065] (104) in Al 0.3 Ga 0.7 On the N layer, a 2nm thick GaN cap layer is grown.

[0066] Step 2. Fabrication of source and drain electrodes.

[0067] refer to figure 1 and image 3 , the specific implementation of this step is as follows:

[0068] (201) Using PECVD equipment to protect the surface of the device with SiN coverage;

[0069] First, put the sample in acetone for 2 minutes, then in ethan...

Embodiment 3

[0087] Embodiment 3, the making of device of the present invention, comprises the following steps:

[0088] Step 1. Epitaxial material growth.

[0089] refer to figure 1 and figure 2 , the specific implementation of this step is as follows:

[0090] (101) On the double-sided polished sapphire substrate, grow a GaN buffer layer by MOCVD process;

[0091] (102) growing an intrinsic GaN layer on the GaN buffer layer;

[0092] (103) On the intrinsic GaN layer, a 20nm thick Al 0.3 Ga 0.7 N layer, intrinsic GaN layer and Al 0.3 Ga 0.7 2DEG is formed between N layers;

[0093] (104) in Al 0.3 Ga 0.7 On the N layer, a 2nm thick GaN cap layer is grown.

[0094] Step 2. Fabrication of source and drain electrodes.

[0095] refer to figure 1 and image 3 , the specific implementation of this step is as follows:

[0096] (201) Using PECVD equipment to protect the surface of the device with SiN coverage;

[0097] First, put the sample in acetone for 2 minutes, then in ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com