Test bed for testing friction torque property of double ball screws

A ball screw, characteristic testing technology, applied in the direction of machine gear/transmission mechanism testing, measuring device, torque measurement, etc., can solve the problems such as the friction torque of the ball screw pair that does not appear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

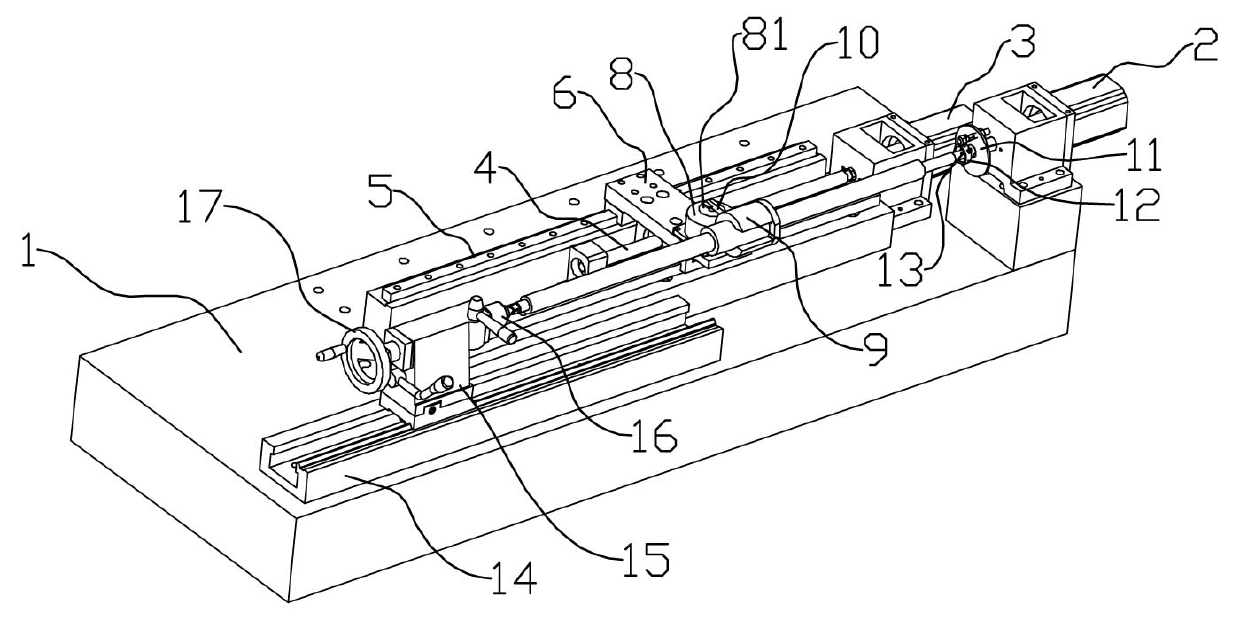

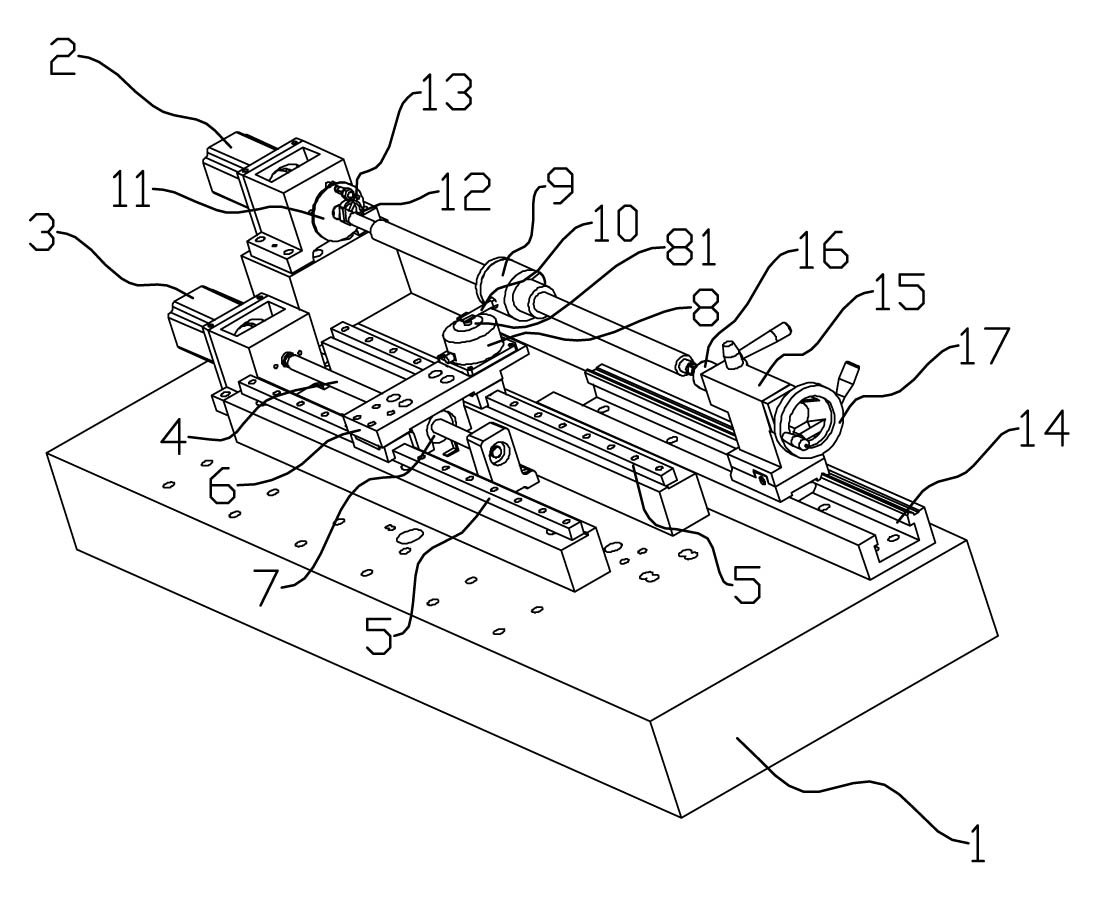

[0012] refer to figure 1 , figure 2 , the double-bar ball screw friction torque characteristic test bench of the present invention includes a base 1 and first and second servo motors 2 and 3 that are installed on the base 1 and controlled by a control system, and the first servo motor 2 is used for To drive the ball screw to be tested, the second servo motor 3 drives the reference ball screw 4, the two sides of the reference ball screw 4 are respectively equipped with linear guide rails 5, and the upper part of the two linear guide rails 5 is equipped with a workbench 6, the workbench 6 is fixed with the reference nut 7 on the reference ball screw 4, a load cell 8 is installed on the workbench 6, and there is a nut sleeve 9 for being installed on the nut of the ball screw to be tested, and the nut sleeve 9 is provided with a The detection end 81 of the load cell 8 is in contact with the cantilever 10 . Due to the adoption of the above-mentioned structure, this double-bar ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com