Cycling elution biomimetic peristaltic enzymolysis reactor and method thereof

An enzymatic hydrolysis reactor and leaching technology, applied in the direction of enzyme production/bioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the difficulty of enzyme recovery, the charging coefficient The problems of low sugar concentration and low sugar concentration can achieve the effect of simple reactor structure, increased contact surface and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

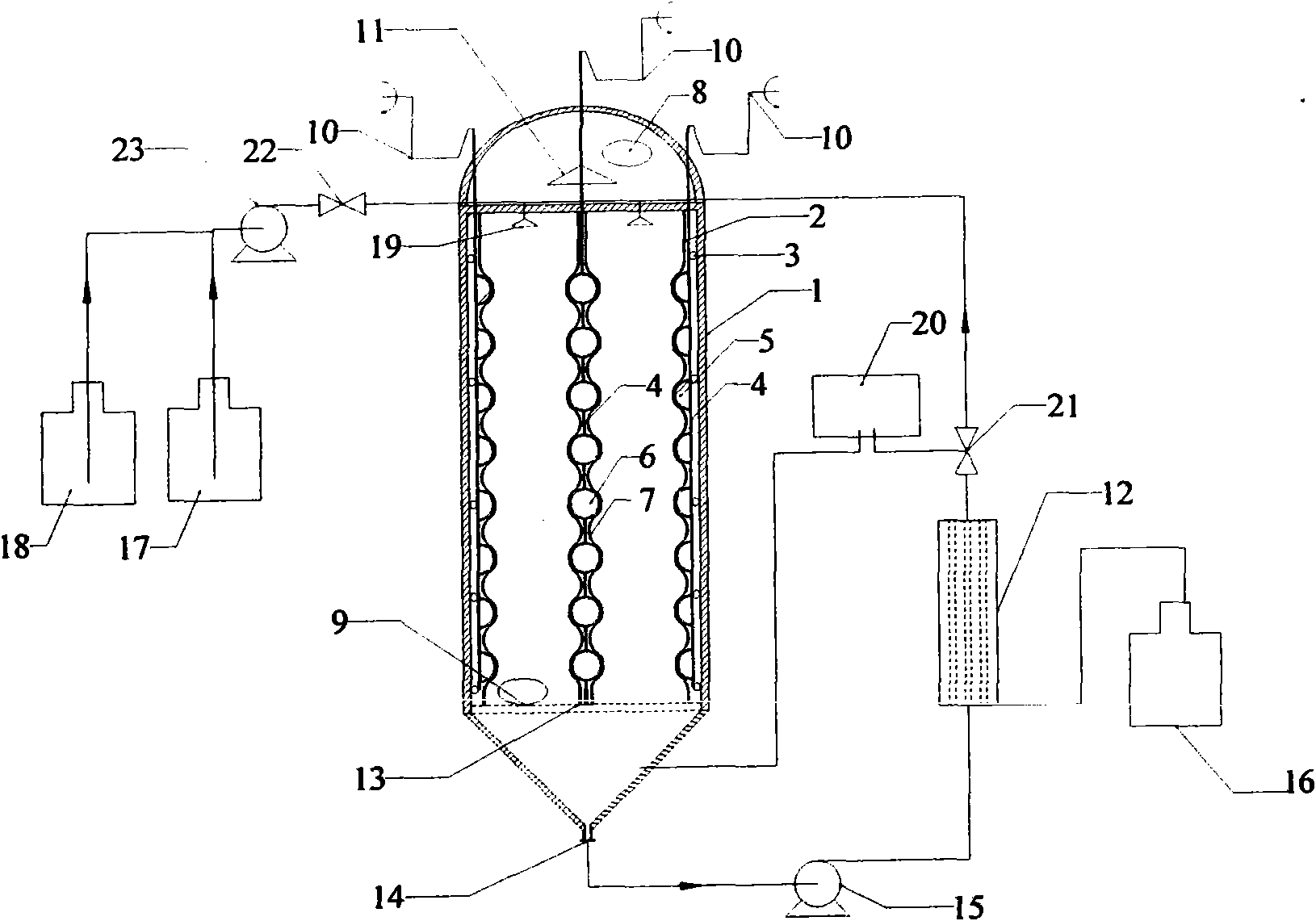

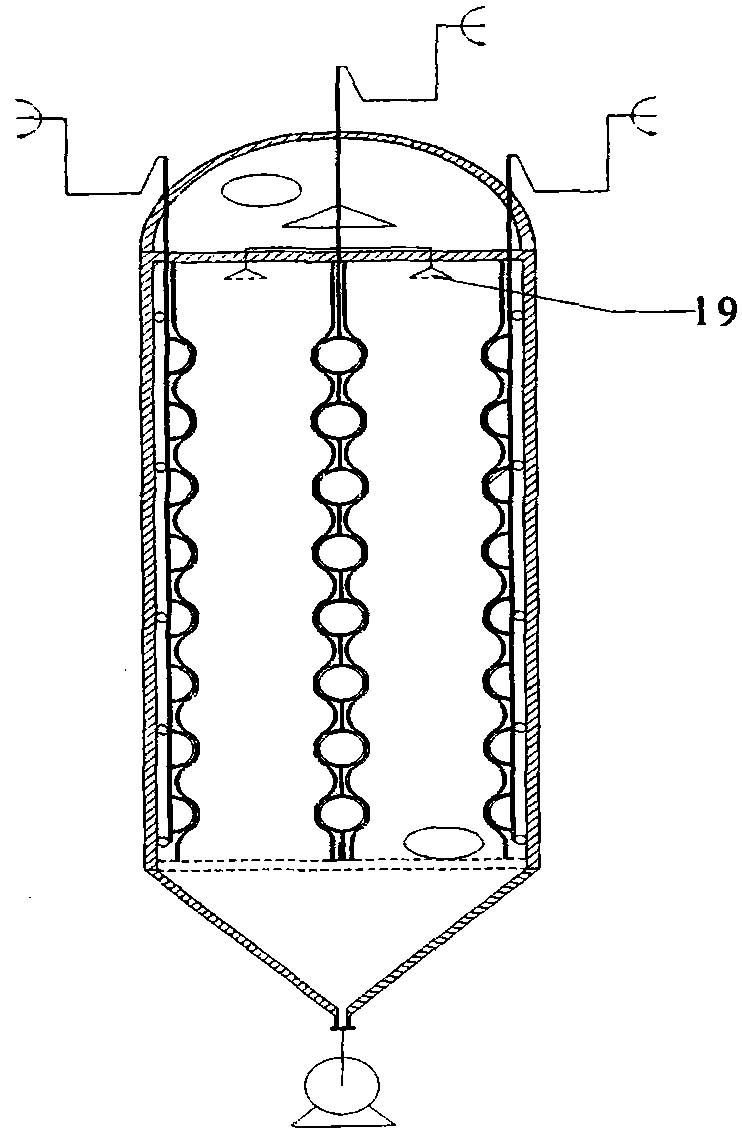

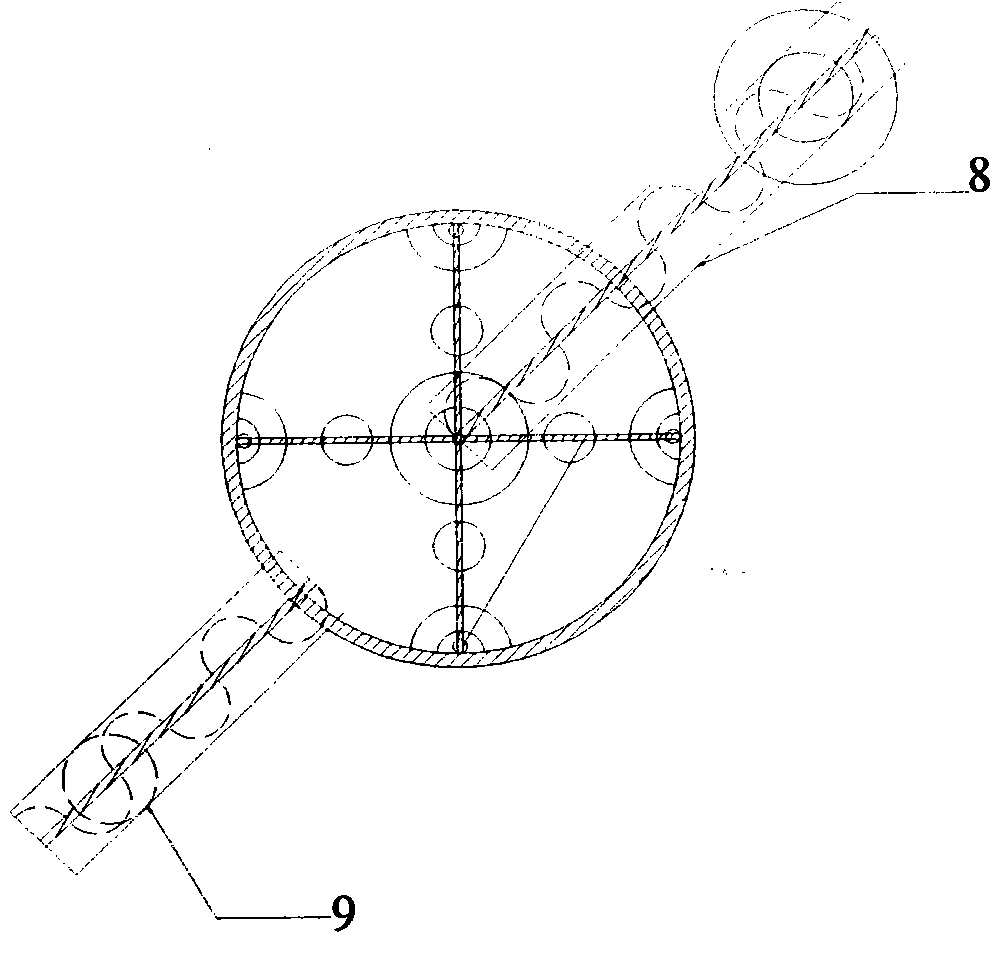

[0038] A bionic peristaltic enzymolysis reactor for cyclic rinsing in this embodiment has a bionic peristaltic main reactor with a height-to-diameter ratio of 2, a total design volume of 50 L, and a bottom distribution diameter of the elastic inner wall of the main enzymatic hydrolysis reactor of 0.5 mm pores, the filter membrane pore size is 75μm, leaching is realized by installing a nozzle, the peristaltic rod is realized by a motor combined with a crankshaft, and the peristaltic rod on the side wall of the reactor moves in parallel in the same direction; the moving speed of the peristaltic rod is 1m / s, and the The cycle interval is 5min.

[0039] The steps of the enzymolysis operation in this reactor are as follows: After the raw material of the steam-exploded straw is sterilized, it is transported to the main reactor for peristaltic enzymolysis by the screw feeder and the distributor, and the charging coefficient of the steam-exploded straw is 85%; The diluted enzyme solut...

Embodiment 2

[0041] This example adopts the enzymolysis reactor of Example 1, and the enzymolysis operation steps are as follows: After the steam-exploded straw raw material is sterilized, it is transported to the peristaltic enzymolysis main reactor by a screw feeder and a distributor, and the steam-exploded straw is The filling factor of the enzyme solution is 90%; the diluted enzyme solution is evenly sprayed on the substrate through the nozzle according to the solid-liquid ratio (w / v, g / ml) of 1:10; Make the steam-exploded straw crawl in the reactor for enzymolysis; at the same time, open the outlet of the enzymolysis liquid at the bottom of the reactor, so that the cellulose enzyme liquid and enzymolysis liquid enter the main enzymolysis reactor through the membrane separation system, and then form a circular rinse through the nozzle ; When the sugar concentration analyzer reaches the preset value, control the pressure at both ends of the membrane module to 0.1 MPa, and add buffer at t...

Embodiment 3

[0043] A biomimetic peristaltic enzymolysis reactor for cyclic rinsing in this embodiment, the bionic peristaltic enzymolysis main reactor has a height-to-diameter ratio of 2.5, a total design volume of 100L, and a bottom distribution diameter of the elastic inner wall of the enzymolysis main reactor is 1mm The pore size of the filter membrane is 200 μm. The leaching is realized by installing a nozzle. The peristaltic rod is realized by a reciprocating piston. The reciprocating cycle time of the peristaltic rod is 20 minutes. The peristaltic rods on the side wall of the reactor move in opposite directions at intervals.

[0044] The steps of the enzymolysis operation in this reactor are as follows: After the raw material of the steam-exploded straw is sterilized, it is transported to the main reactor for peristaltic enzymolysis by the screw feeder and the distributor, and the charging coefficient of the steam-exploded straw is 80%; The diluted enzyme solution is evenly sprayed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com