Reactor for preparing tetrabromoethane by addition reaction of bromine and acetylene and synthesis process

A technology of tetrabromoethane and addition reaction, applied in the field of reactor and synthesis process, can solve the problems of reaction influence, explosive mixture of acetylene and air, and the inability to remove reaction heat in time, achieve continuous synthesis and improve production efficiency , avoid the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

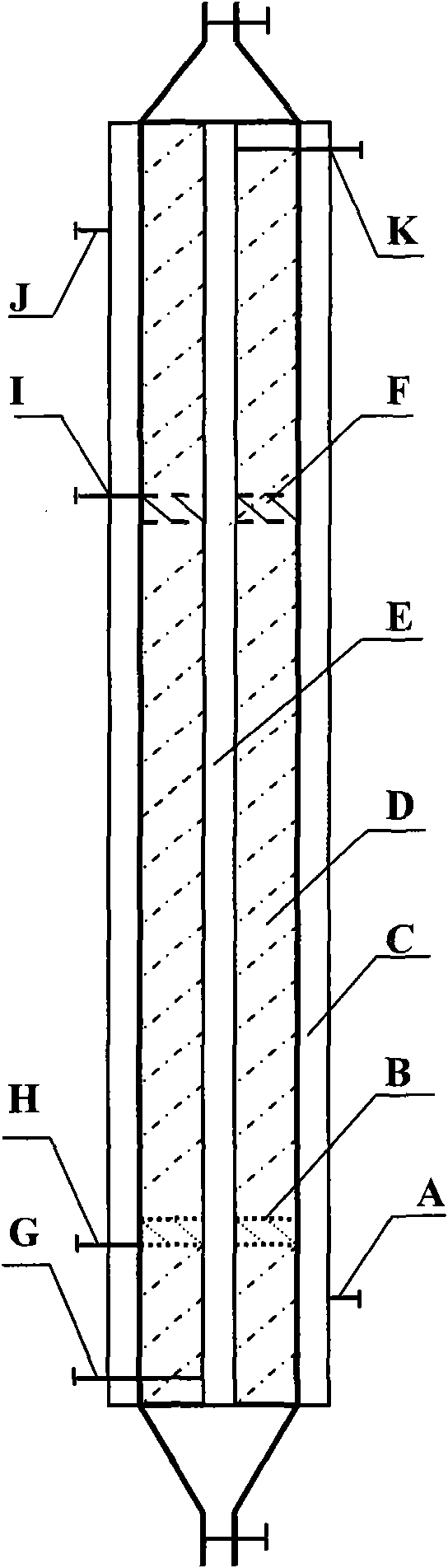

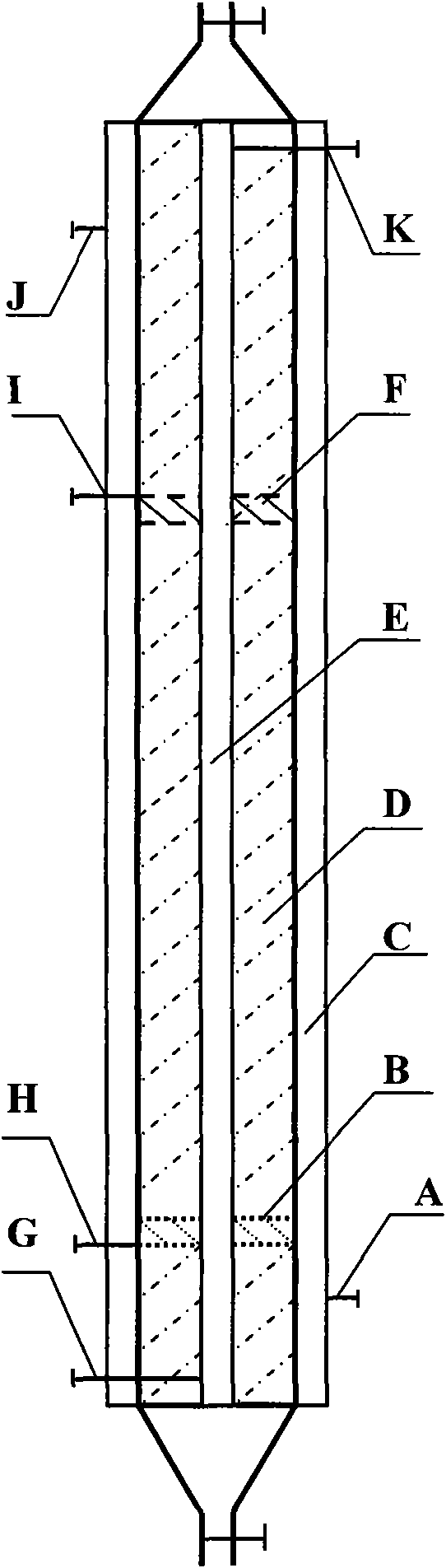

[0019] The reactor used for the addition reaction of bromine and acetylene to prepare tetrabromoethane has the following main parameters:

[0020] The total length of the reaction tube is 2.2m, the filling height in the reaction tube is 2m, and the filling diameter in the tower Borosilicate glass θ mesh ring type packing. The length of the central cooling pipe and the outer cooling pipe are 2m respectively. The diameter of the central cooling tube is 50mm, the diameter of the reaction tube is 100mm, and the diameter of the outer cooling tube is 150mm. The material of the reactor is borosilicate glass.

[0021] The synthesis process of tetrabromoethane is described below. The acetylene gas enters the reaction tube through the acetylene gas distributor and is evenly distributed in the tube. The acetylene gas moves from bottom to top under pressure and fills the reaction tube, completely exhausting air. Then, bromine enters the reaction tube from the feed port, and the bromine flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com