Method for preparing SiC heating element having long service life

A heating element, long-life technology, applied in the direction of heating element materials, etc., can solve problems such as short life, and achieve the effect of improving service life and small local resistance changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

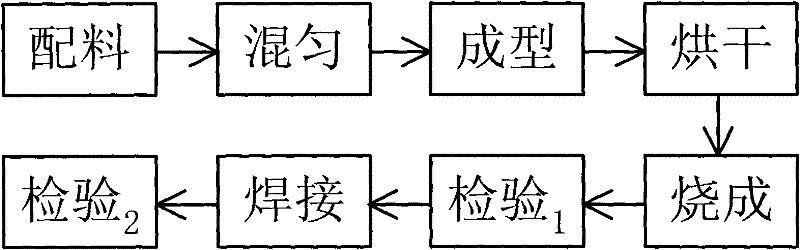

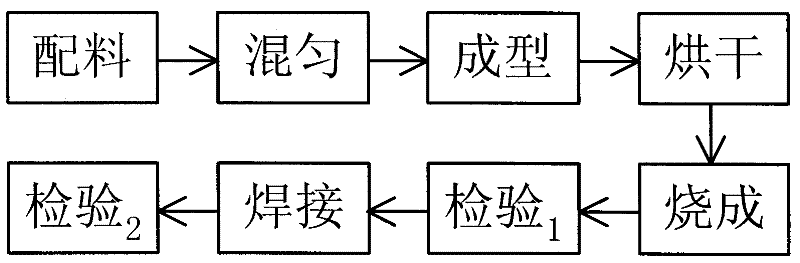

[0015] see figure 2 The process flow chart for the preparation of the SiC heating element of the present invention, the heating part 1 and the cold end part 2 both involve the steps of batching, mixing, molding, drying, firing and inspection. The specific examples of the heating part are shown in Table 1. The specific embodiment of the cold end is shown in Table 2.

[0016] Table 1 Formula composition and process parameters of the heating part

[0017]

[0018] Formulation composition and process parameters of the cold end of table 2

[0019]

[0020] exist figure 2 In the process shown, the inspection 1 process is to detect the thermal state of the resistance value (resistivity) of the sintered heating part 1 or the cold end part 2, and the detection temperature is 1100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com