Combustor of large rotating furnace

A burner and converter technology, applied in the field of smelting furnace components, can solve problems such as temperature drop in the furnace, poor smelting effect, and extended furnace time, and achieve the effect of reducing the number of shutdowns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with the embodiment shown in the accompanying drawings, the invention is described in further detail:

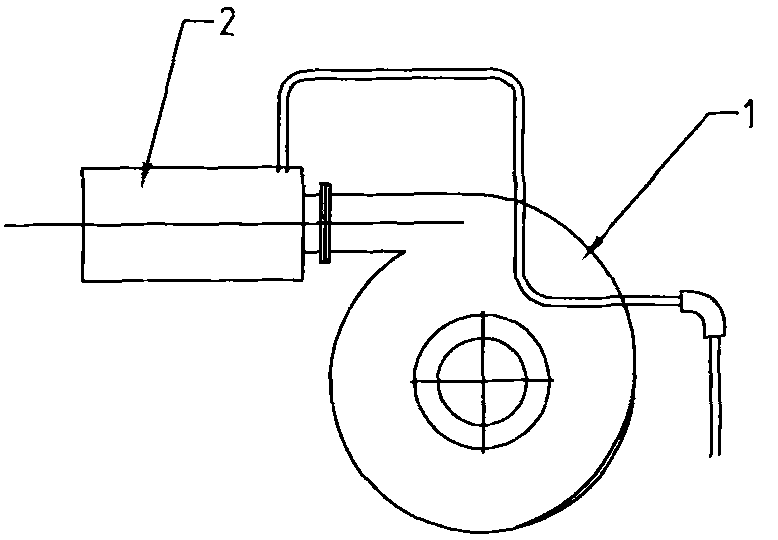

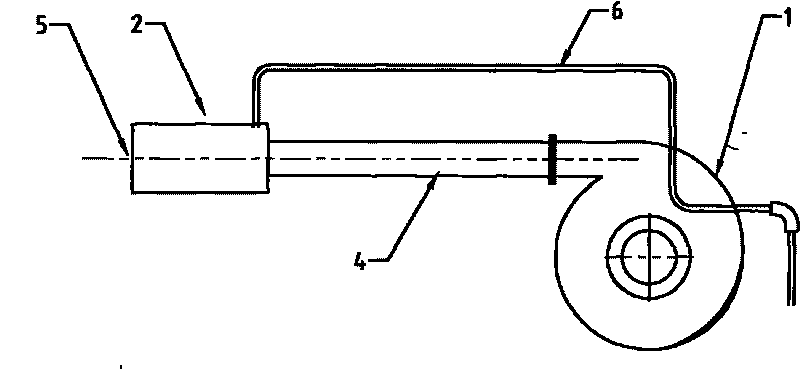

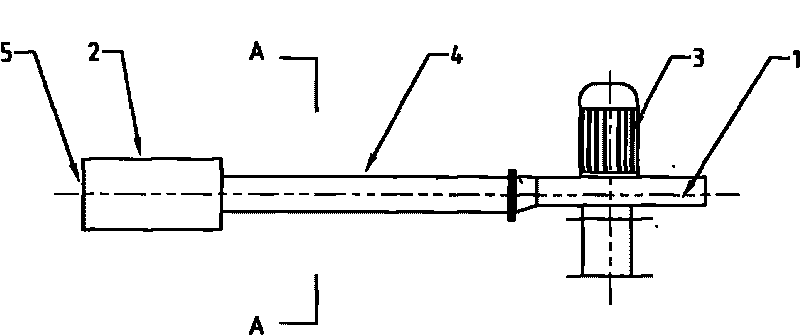

[0013] like figure 2 , 3 Shown is a large converter burner, including a blower 1, a blower motor 3 and a cylindrical burner 2 of high titanium steel; the cylindrical burner 2 is provided with a fuel injection pipe 6; An air duct 4 is added between the cylindrical burners 2 of titanium steel to lengthen the distance between the center of the blower motor 3 and the burner 5 .

[0014] Figure 4 Shown is the air duct 4 added to the large converter burner, which is a square air duct with a length of 1000-1500 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com