Rear heat shield structure of auto muffler

A technology of automobile mufflers and heat shields, which is applied in the direction of mufflers, machines/engines, engine components, etc., can solve the problems of poor rigidity in the middle part, improved NVH performance, and low natural frequency, and achieves improved structural rigidity, simple structure, The effect of increasing the natural frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

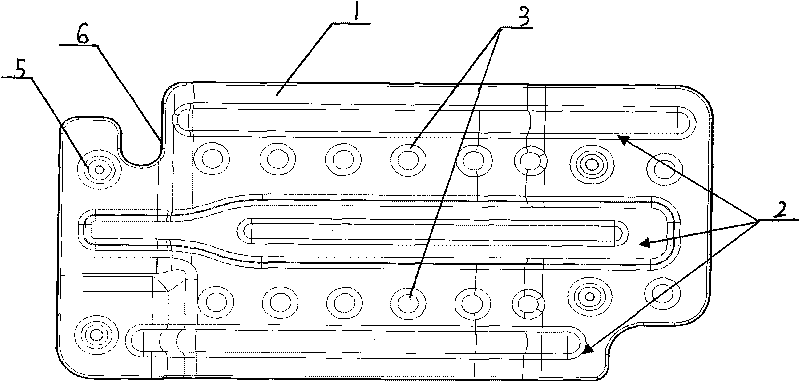

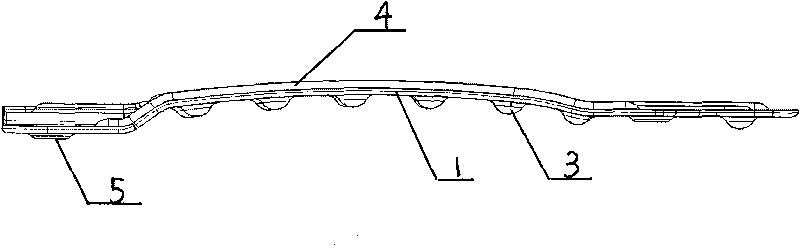

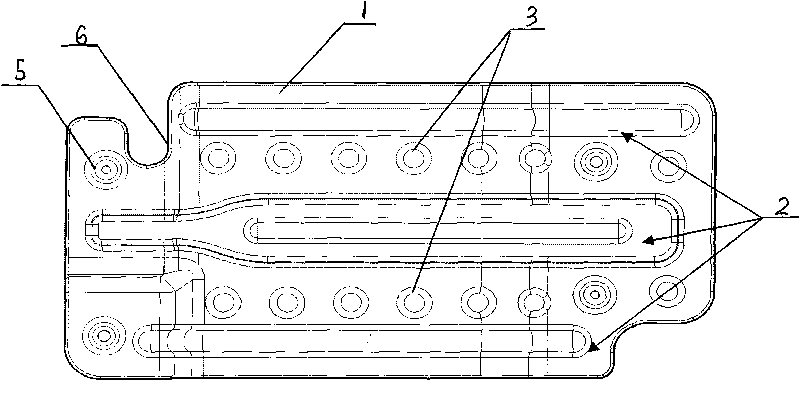

[0011] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

[0012] see figure 1 with figure 2 , the rear insulation plate of the automobile muffler is a rectangular plate as a whole, and there are mounting holes 5 for assembling with the automobile beam on the left and right sides of the rear insulation plate, which are connected with the car body by screws. Left upper left corner and the lower right corner of the rear heat shield have a gap 6 for easy assembly. The rear insulation board is arched in the middle and flat at both ends in the length direction, avoiding a large plane structure in the case of a large span, and is conducive to the improvement of the overall rigidity. At the same time, three long reinforcing ribs 2 extending along the length direction are stamped on the board surface, and the three long reinforcing ribs are arranged in parallel on the board surface in the upper, middle and lower sides, so as to im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com