Nylon fiber manufacturing machine capable of productivity increase

A nylon fiber and manufacturing machine technology, applied in fiber processing, textile and papermaking, melt spinning, etc., can solve the problems of nylon fiber product production speed and output limitation, inability to cope, and achieve production speed improvement, increase production capacity, and quickly The effect of completing the delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it after studying this specification.

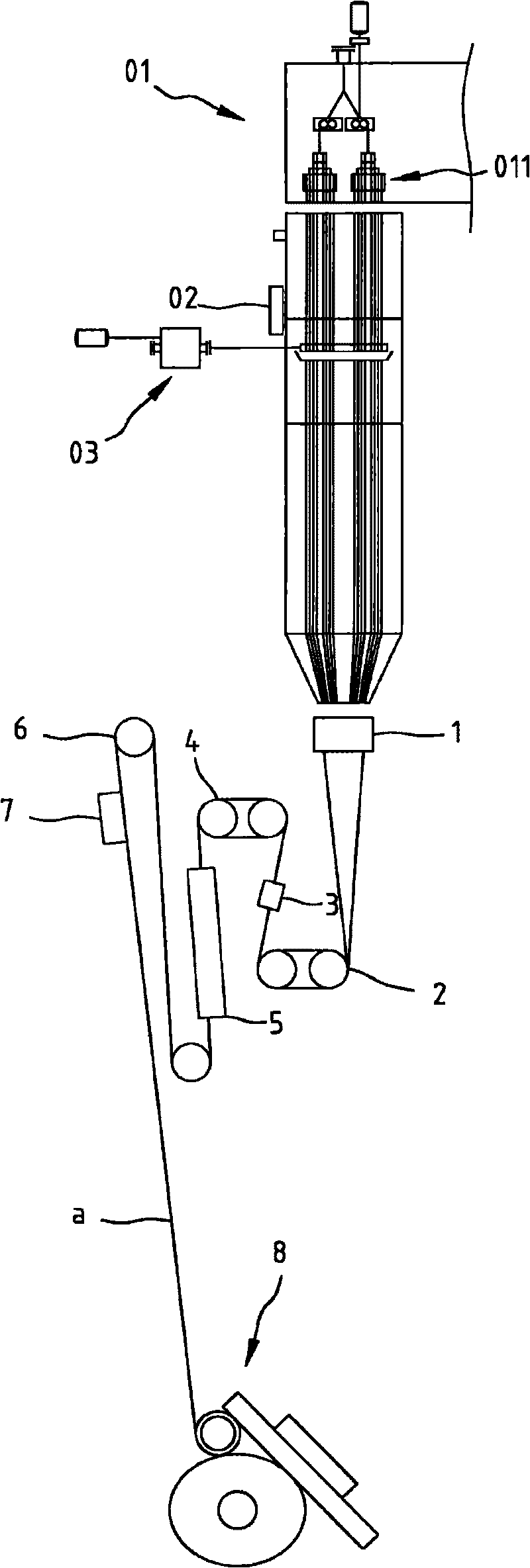

[0027] Such as figure 1 As shown, the nylon fiber manufacturing machine that can increase the production capacity of the present invention includes a plurality of spinning devices 01, which have a plurality of spinning holes 011;

[0028] A plurality of cooling devices 02, a plurality of first oiling devices 03, a plurality of suction openings 1, and a plurality of first guide wheel sets 2, a plurality of extension guide wheel sets 4, a plurality of A guide wire guide wheel set 6 and a plurality of coiling devices 9;

[0029] A plurality of steam stretching devices 3 are arranged at the place where the fiber filament a passes between the first guide wheel set 2 and the extension guide wheel set 4;

[0030] A plurality of steam setting devices 5 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com