Direct vertical deposition method of zinc oxide nanometer rod array on titanium dioxide film

A zinc oxide nanorod and nano titanium dioxide technology, which is applied in liquid chemical plating, superimposed layer plating, and devices for coating liquid on the surface, etc., to achieve the effects of improving optoelectronic properties, convenient operation, and easy industrialized production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

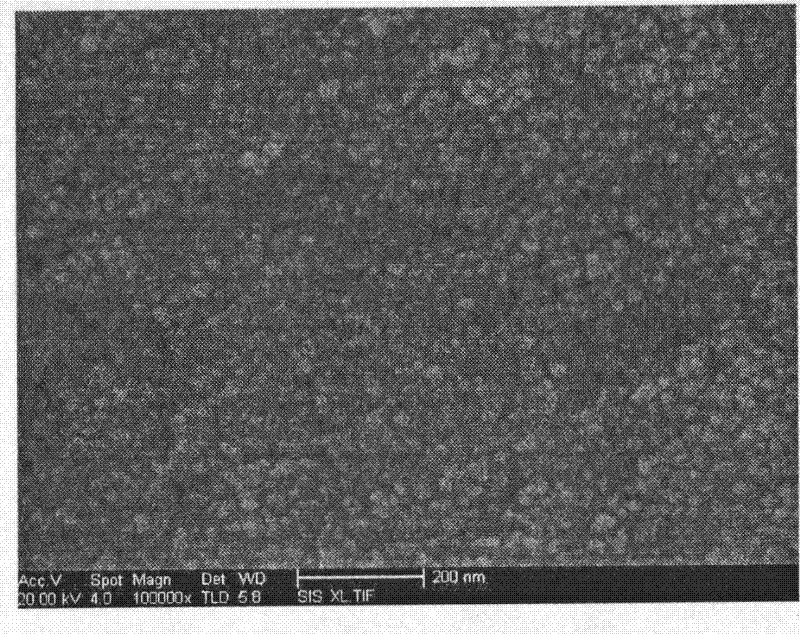

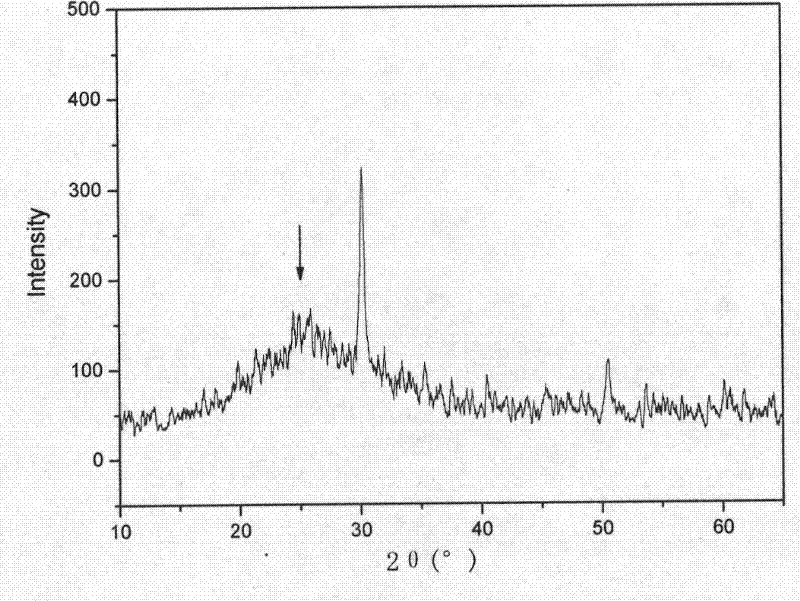

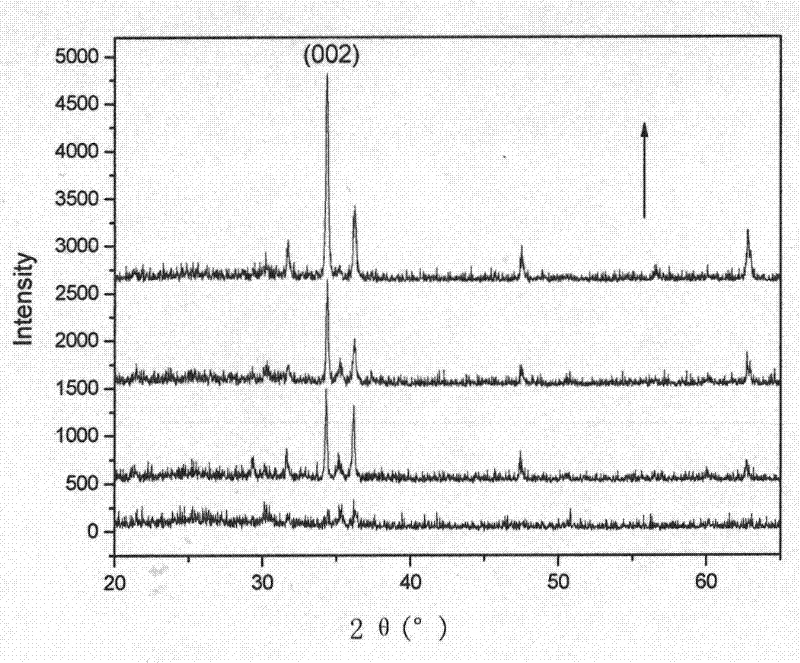

[0036] The direct vertical deposition method of zinc oxide nanorod arrays on titanium dioxide film, at room temperature, prepare titanium dioxide sol, pretreatment, and attach a layer of titanium dioxide sol on pretreated glass or conductive glass ITO by dipping and pulling methods , dry, the titanium dioxide nanoparticles will be pretreated before spin coating, and then adopt the method of spin coating to fix a layer of titanium dioxide nanoparticles prepared by sol-hydrothermal method on the above-mentioned film, dry, and roast to obtain nano titanium dioxide thin films. The film is placed in a sealed aqueous solution system of zinc salt and organic amine, reacted at a reaction temperature of 45-90° C. for 12-72 hours, taken out, washed with secondary water, and dried.

[0037] In the direct vertical deposition method of the zinc oxide nanorod array on the titanium dioxide film, the preparation of the titanium dioxide sol is to drop 2 mL of secondary water into 6 mL of tetrab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com