Sweet potato seedling planting machine based on secondary precise shaping special-shaped ridge

A technology of sweet potato seedlings and planting machines, which is applied in the direction of transplanting machinery, cultivation, planting methods, etc., and can solve the problems of uniform growth shape of potato seedlings, reduced sweet potato yield, difficulty in controlling insertion angle and depth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

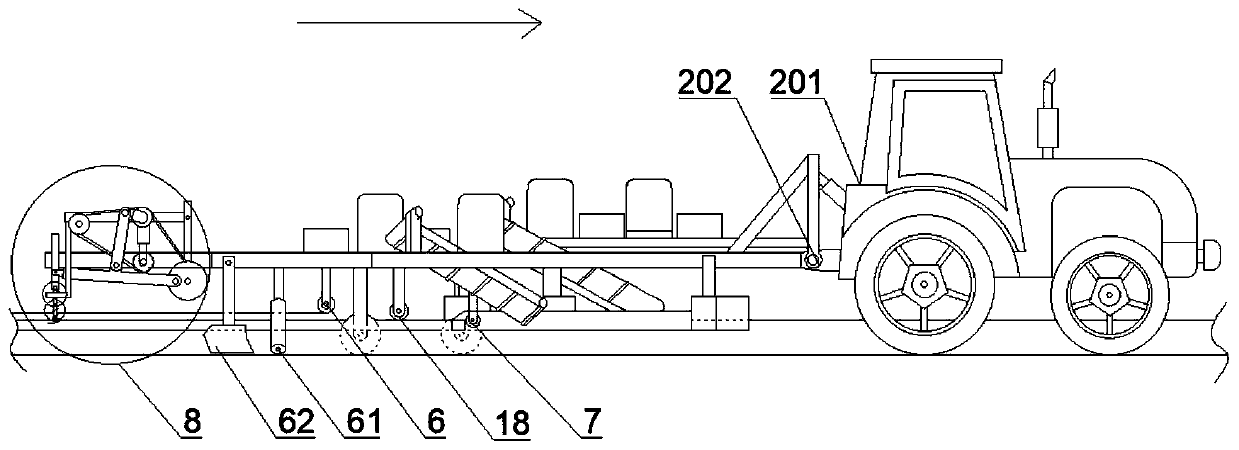

[0027] The present invention is a planting machine for sweet potato seedlings based on secondary precisely shaped shaped ridges, which can complete the planting process of two rows of sweet potato seedling drop, shaping, soil covering, laying of drip irrigation belts, plastic film covering and seedling removal at one time, which is convenient for personnel to operate. Improve the efficiency, improve the growth form of sweet potato seedlings, and increase the yield of sweet potato.

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

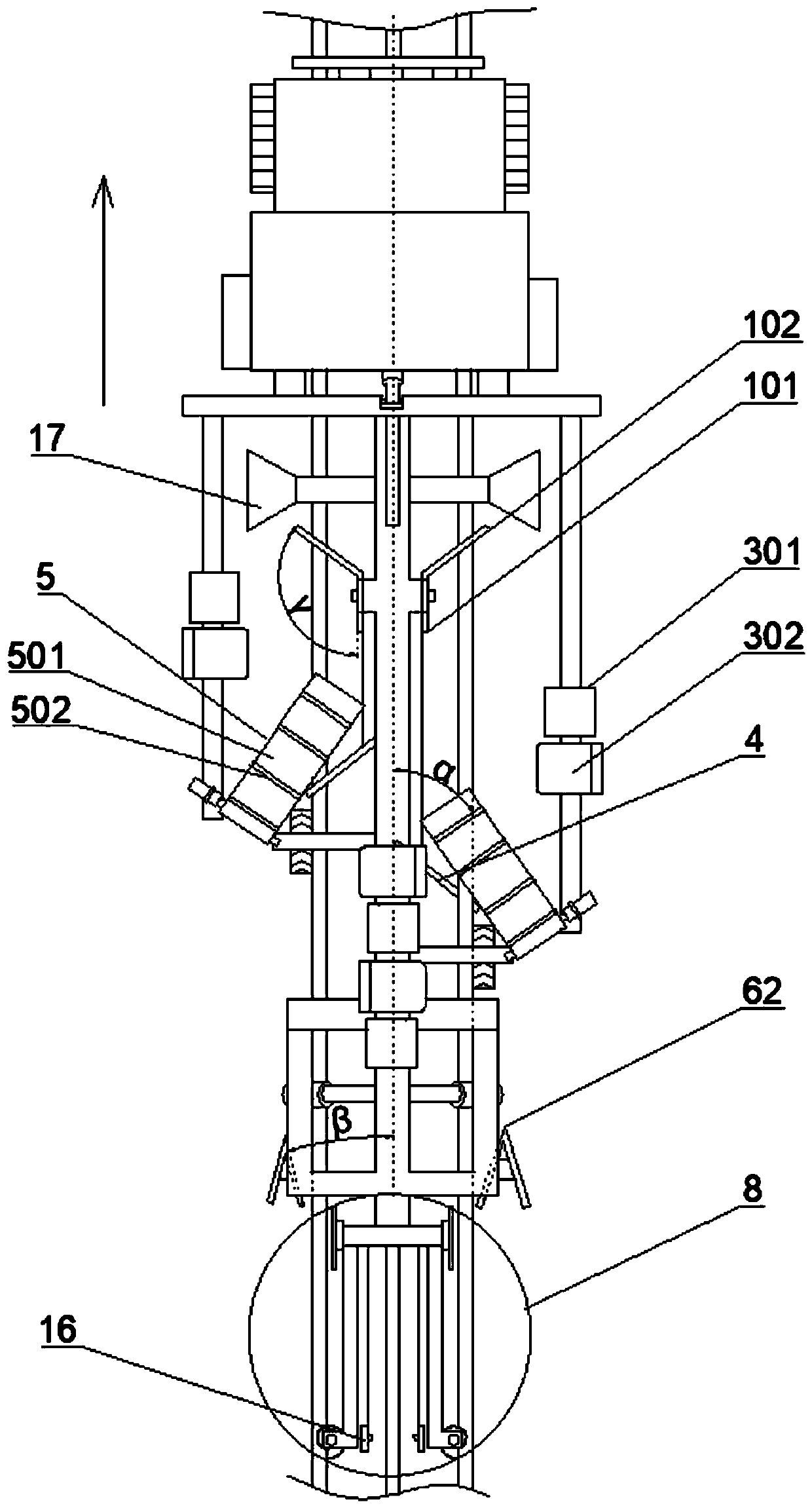

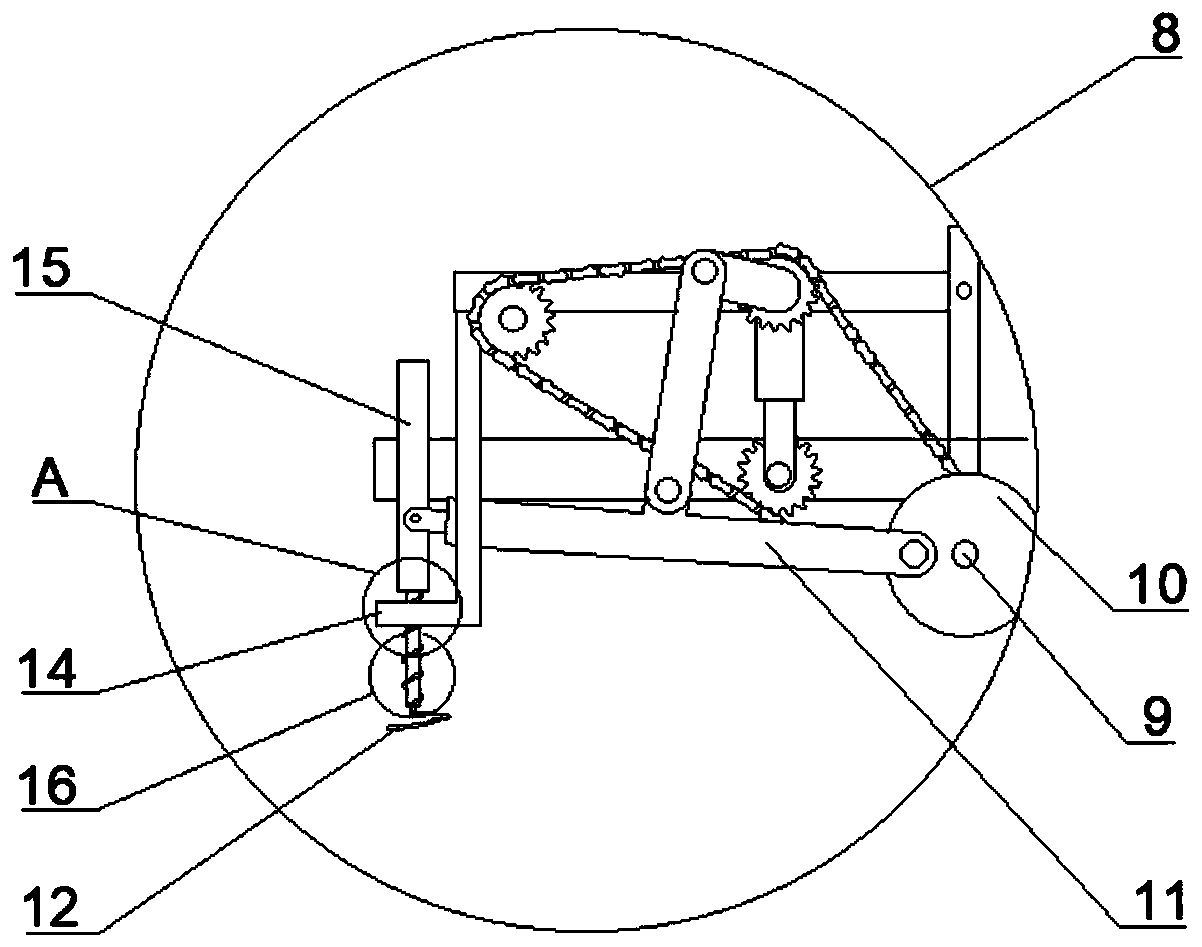

[0029] Such as figure 1 , 2 As shown, a kind of sweet potato seedling planting machine based on the secondary precise shaped shaped ridge is installed on the rear of the tractor 201, and the structure includes a frame 202 connected with the tractor 201 and suspended above the field ridge. There is a planting mechanism, the key is: the planting mechanism includes a bulld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com