Method for preparing friction lining

A friction pad and formula technology, applied in the field of friction pads, can solve problems such as the inability to meet the requirements of users, and achieve the effects of good processing performance, excellent comprehensive mechanical properties, and good melting resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

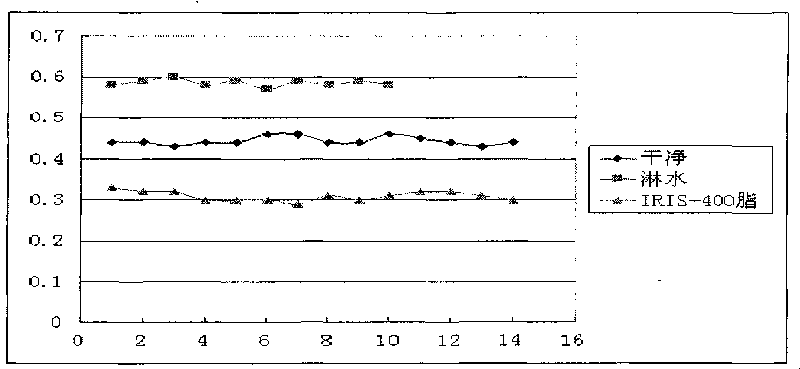

Image

Examples

Embodiment 1

[0020] According to its formula mass parts: imported nitrile rubber 100, imported powdered nitrile rubber 40-80, imported phenolic resin 100-200; montmorillonite 20-60, active silica powder 15-45, nano CaCO 3 25-75; vulcanization system DCP 2-4, TMTD 0.5-1.5, ZnO 10-25, MgO 10-25, Fe 2 o 3 5-20; against D 0.5-1.5, against A 1-2.5; DOP 15-30.

Embodiment 2

[0022] Take imported nitrile rubber according to the formula, first preheat the roll on the open mill, and then add imported powdered nitrile rubber, DOP, ZnO, MgO, Fe 2 o 3 , Nano CaCO 3 , anti-A, anti-D, montmorillonite, and activated silica powder, knead for 20 minutes at 60-80°C, then add phenolic resin, knead for 20 minutes at 60-80°C, and finally Add DCP and TMTD, and knead for 10 minutes at 60-80°C, and the mixing is complete.

Embodiment 3

[0024] After the mixed raw materials are placed for 24 hours, put them into the mold, pressurize 20MPa-25MPa at a temperature of 120°C-180°C, and start to heat up after exhausting and overflowing, and start heat preservation when the temperature reaches 180°C Press and form, start to cool down after heat preservation and pressure holding, when the temperature drops to 120°C, demould, deburr, and make a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com