Framework type track gauge and track direction measuring device

A technology of measuring device and gauge, which is applied in the directions of measuring device, transportation and packaging, adopting optical device, etc., can solve the problems such as the inability to detect the gauge and track direction at high speed, the safety hazard of the axle box gauge detection beam, etc., and meet the requirements of The demand for transportation safety and detection accuracy, and the effect of solving potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

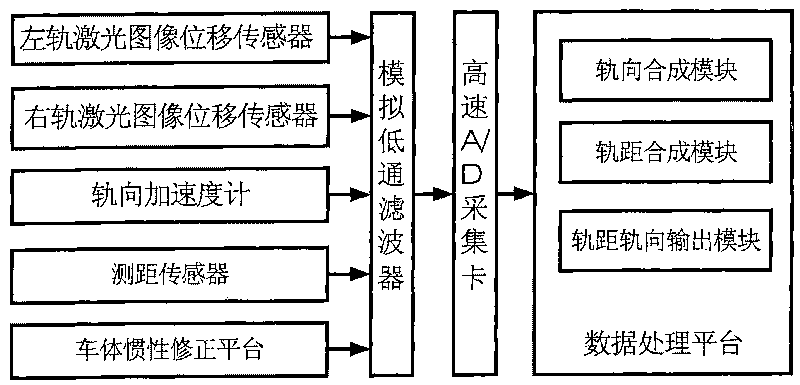

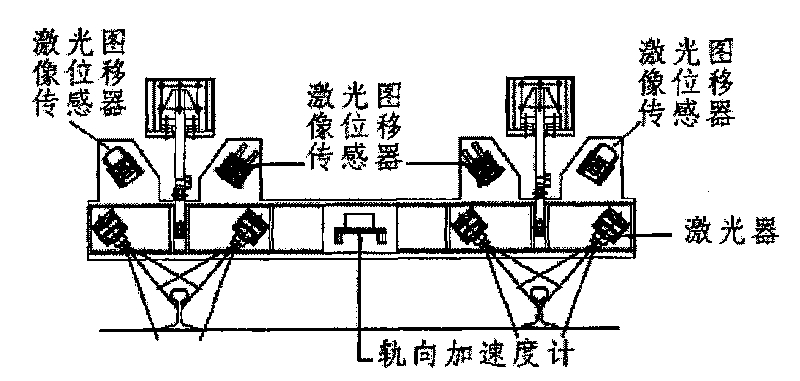

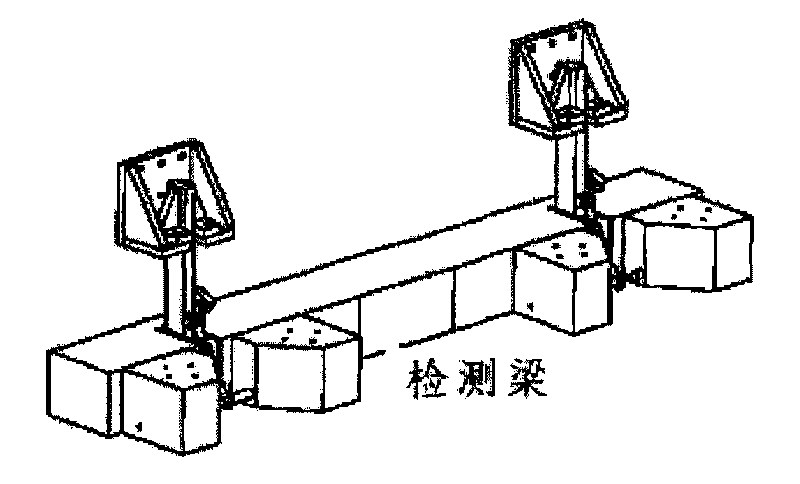

[0021] see Figure 1-Figure 3 ,in, figure 1 It is a structural schematic diagram of an embodiment of the frame gauge and track direction measuring device of the present invention, figure 2 It is a structural schematic diagram of an embodiment of the detection beam part of the frame gauge and track direction measuring device of the present invention, image 3 It is a schematic diagram of the appearance of the detection beam of the frame-type gauge and direction measuring device of the present invention.

[0022] This embodiment provides a framed gauge and track direction measuring device, which includes:

[0023] The detection beam is arranged under the track inspection vehicle perpendicular to the track; different from the prior art, the embodiment of the present invention sets the detection beam on the track inspection vehicle body in a framed manner, instead of the prior art track inspection vehicle On the rail axis, the vibration interference can be reduced.

[0024] T...

Embodiment 2

[0032] see again Figure 4 , Figure 4 It is the measuring principle diagram of the framework gauge and track direction measuring device of the present invention.

[0033] As shown in the figure, the left and right deviation of the track gauge is measured by laser image method, and the inertial measurement method is used for the track direction. The measurement principle of the track direction system is shown in Figure 4 .

[0034] For the definition of mutual positional relationship between the detection beam and the rail Figure 4 .

[0035] The output of the laser image measurement sensor mounted on the detection beam is as follows:

[0036] g L The displacement of the left gauge point relative to the detection beam (left gauge offset value);

[0037] g R The displacement of the right gauge point relative to the detection beam (right gauge offset value);

[0038] p L The displacement of the apex of the left rail surface relative to the detection beam (left high an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com