Motor rotor

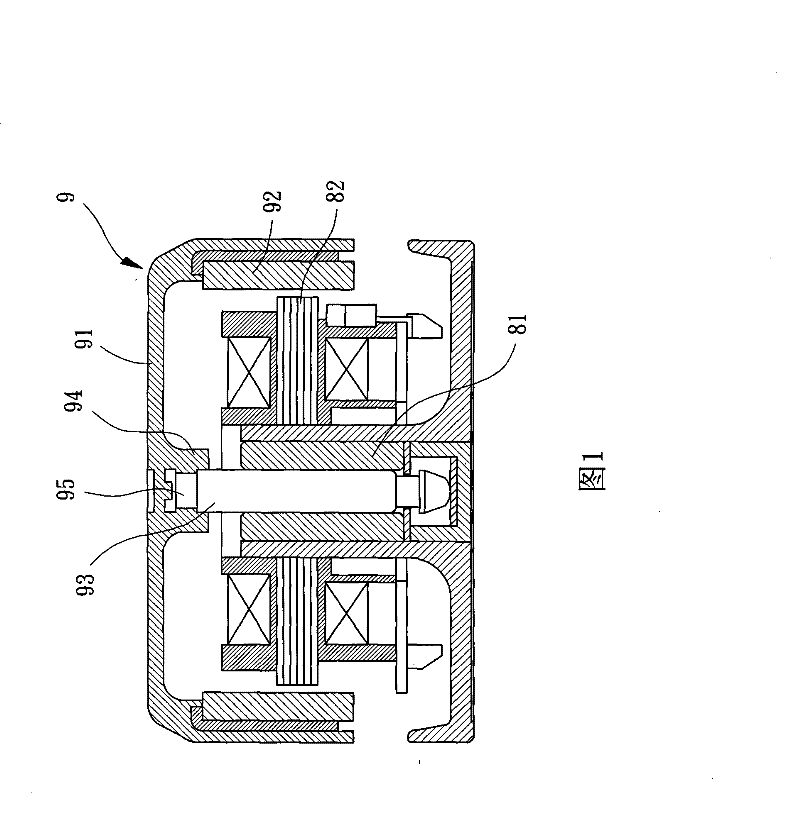

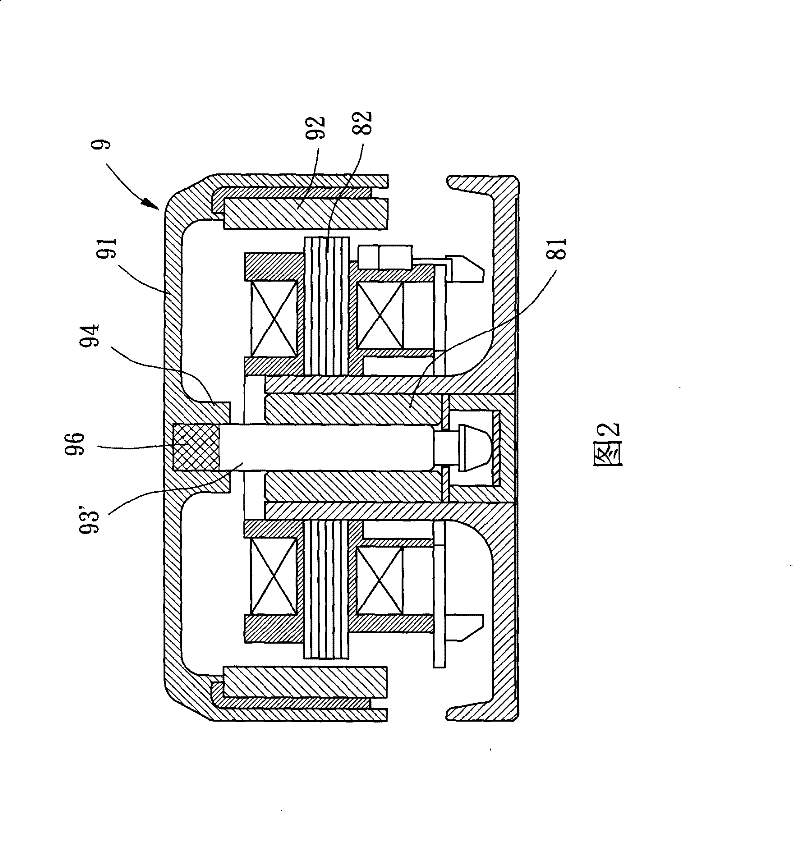

A technology for motor rotors and hubs, which is applied in the direction of magnetic circuit rotating parts, mechanical energy control, electric components, etc., and can solve problems such as the limited area of the hub 91, the limited design space for miniaturization or thinning of the motor, and the reduction of the combined area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

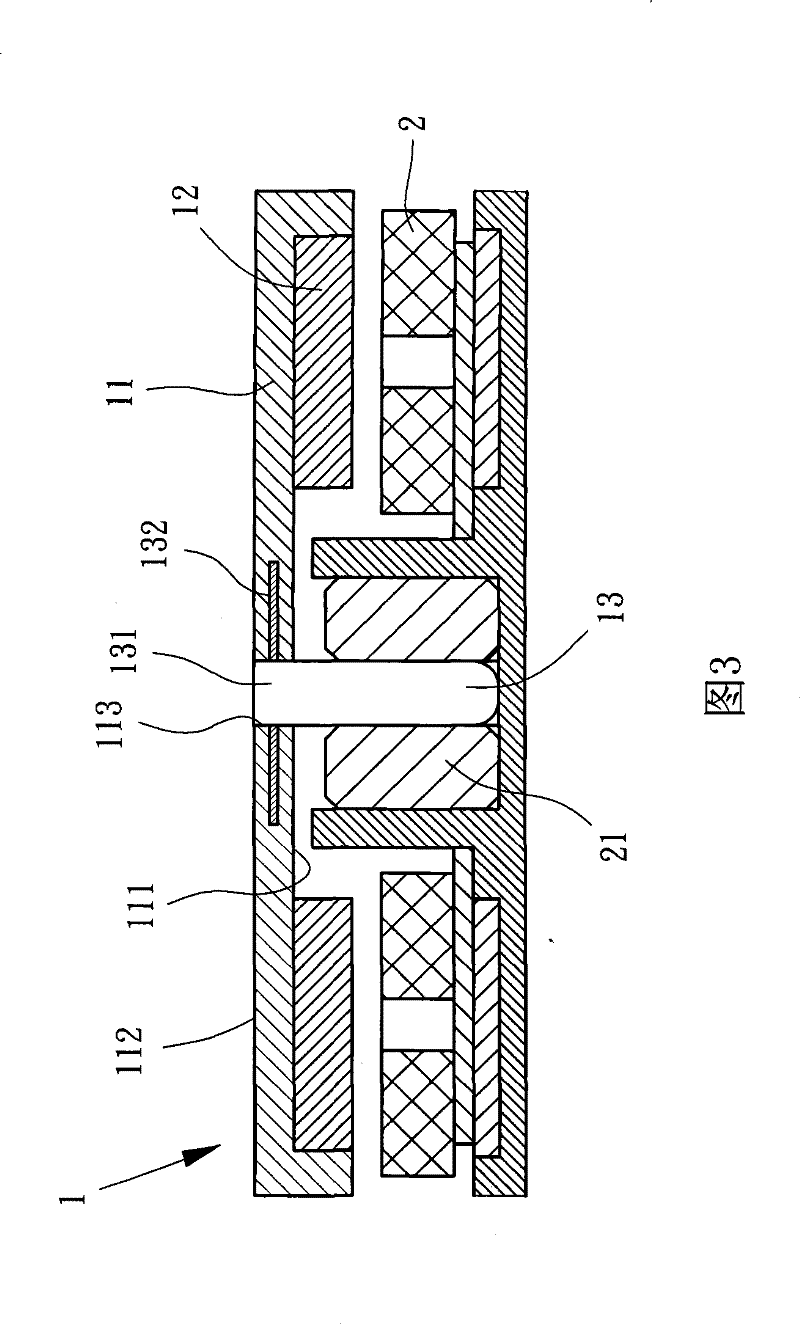

[0035] Please refer to image 3 As shown, the rotor 1 of the first embodiment of the present invention includes a hub 11 , a permanent magnet 12 and a spindle 13 .

[0036] Two opposite sides of the hub 11 are respectively an inner surface 111 and an outer surface 112 , and an assembly hole 113 is defined in the center of the hub 11 . Wherein, the assembling hole 113 may be selected as a blind hole (not shown), or may be selected as a through hole penetrating from the inner surface 111 to the outer surface 112 of the hub 11 (as shown in this embodiment).

[0037] The permanent magnet 12 is disposed on the inner surface 111 of the hub 11 , and is preferably disposed around the outer periphery of the assembly hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com