Electro-optical switch with low half-wave voltage

An electro-optic switch and half-wave voltage technology, applied in the field of optoelectronics, can solve the problem that the electro-optic crystal cannot be too long

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

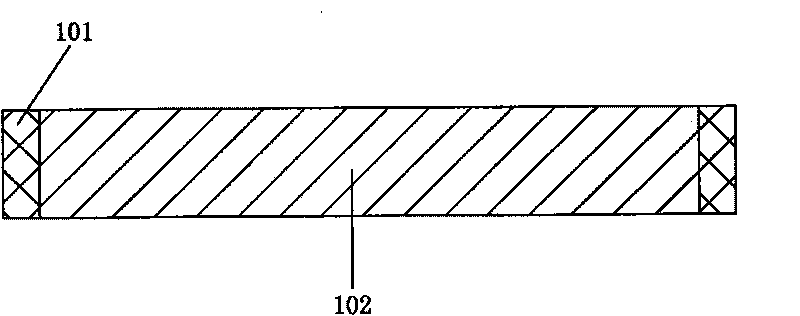

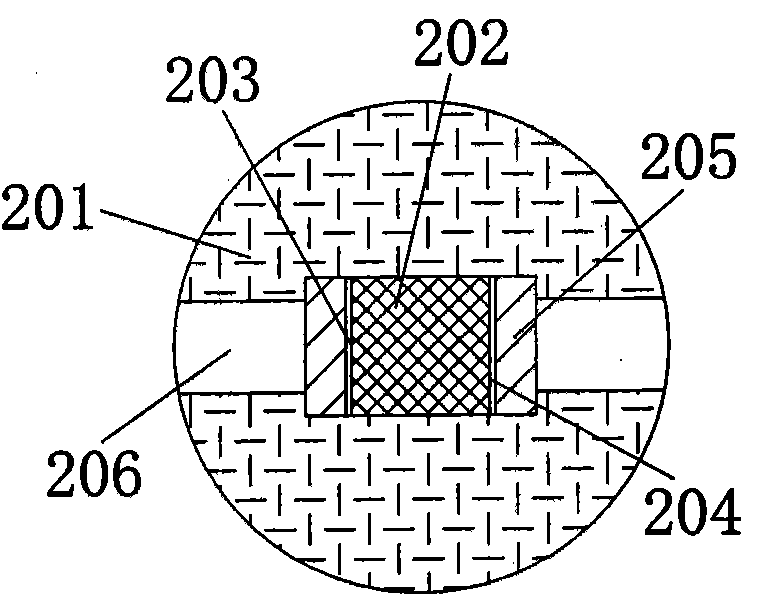

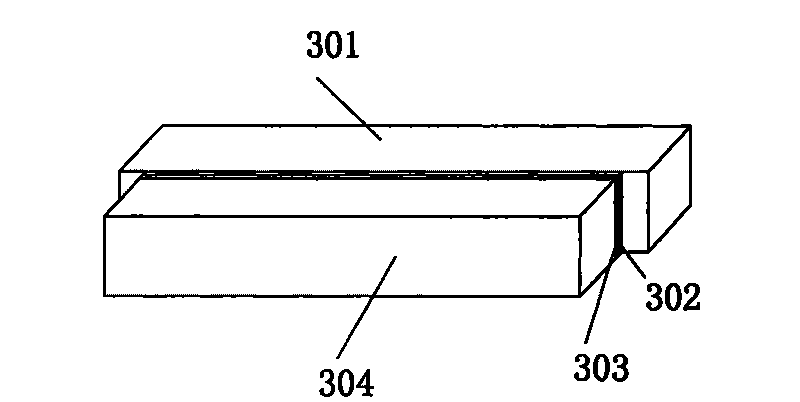

[0033] Example 1 The packaging implementation mode of the electro-optical switch of the present invention for single crystal or double crystal optical glue or glue or bond 1 see figure 1 , figure 2 and image 3 . The electro-optic switch in the figure includes a cylindrical insulating shell 201; there is a rectangular slot in the center of the shell, and an electro-optic crystal 202 is placed in the middle of the slot. The crystal can be BBO or LiNbO3 or LiTaO3 or RTA or RTP or KTP or LGS, etc., they It can be single crystal or double crystal photoresist or glued or bonded; a pair of sides of the crystal is plated with a metal conductive layer 203, and the length of the conductive layer is slightly shorter than the length of the crystal side; the metal conductive layer is attached with the same length or A slightly shorter indium foil 204; the indium foil is closely attached to the inner metal electrode 205 of the same length or slightly shorter; the outer metal electrode i...

example 2

[0034] Example 2 For the packaging implementation mode 2 when the electro-optic switch of the present invention is used for double directly fixed crystals, see Figure 4 and Figure 5 . The electro-optic switch in the figure includes a cylindrical insulating shell 401; there is a rectangular slot in the center of the shell, and a pair of directly fixed electro-optic crystals 402 are placed in the middle of the slot, and they are arranged in series. The double crystals can be BBO or LiNbO3 or LiTaO3 or RTA or RTP or KTP or LGS, etc.; a metal conductive layer 403 is plated on a pair of sides of the crystal respectively, and the length of the conductive layer is slightly shorter than the length of the side of the crystal; the metal conductive layer is attached with an indium foil of the same length or slightly shorter 404; the indium foil is closely attached to an internal metal electrode 405 of the same length or slightly shorter than the indium foil; the internal metal electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com