Reagent reacting cup and fully automatic inspection and detection instrument

A detection instrument and reaction cup technology, which is applied in the field of medical detection, can solve the problems of blocked automatic operation, waste, collision of reagent reaction cups, etc., and achieves the effects of convenient access, prevention of liquid residue, and reduction of non-specific reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the figures.

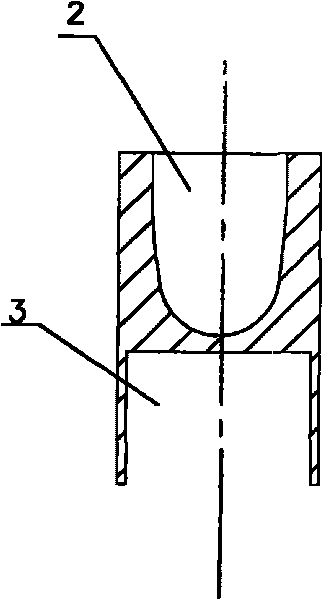

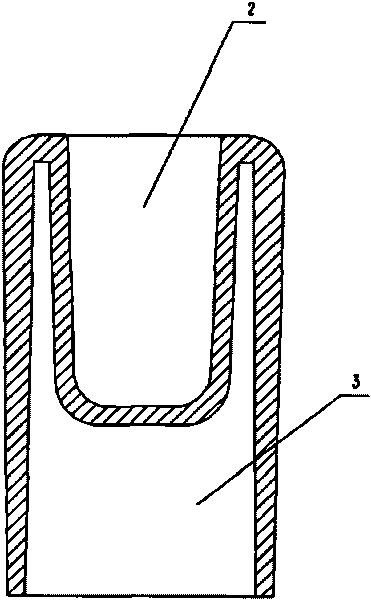

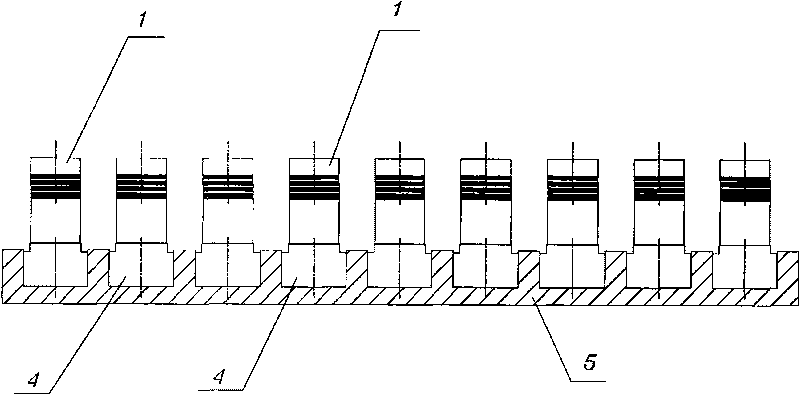

[0029] Figure 1A It is a schematic diagram of the structure of the reagent reaction cup, including the inner cavity 2 of the cup containing the reagent. The shape of the cup body is cylindrical, and the bottom of the cup is recessed inward to form a cavity 3, so that the reagent reaction cup 1 can be stably placed on a plane or a carrier by itself. It can also be fixed on the boss of the carrying device through the cavity 3 at the bottom. The reagent cuvette is higher than the plane of the carrying device at a certain height, which is convenient to take and place. Since the reagent cuvette has no upper fixed boss, the reagent cuvette will not collide with each other, and the reagent cuvette is set as a cylinder, which can be conveniently operated or taken from all directions of the reagent cuvette, and the bottom of the boss connected with the reagent cuvette is the reagen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com