Medium light-heat-conversion glass composite pipe pressure-bearing solar vacuum energy-exchanging tube

A light-to-heat conversion and composite tube technology, which is applied in the field of solar energy applications, can solve problems such as system failure, the structural characteristics of all-glass solar vacuum heat collector tubes that cannot withstand pressure, and cannot meet the pressure-bearing operation of the system, achieving high safety and easy processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

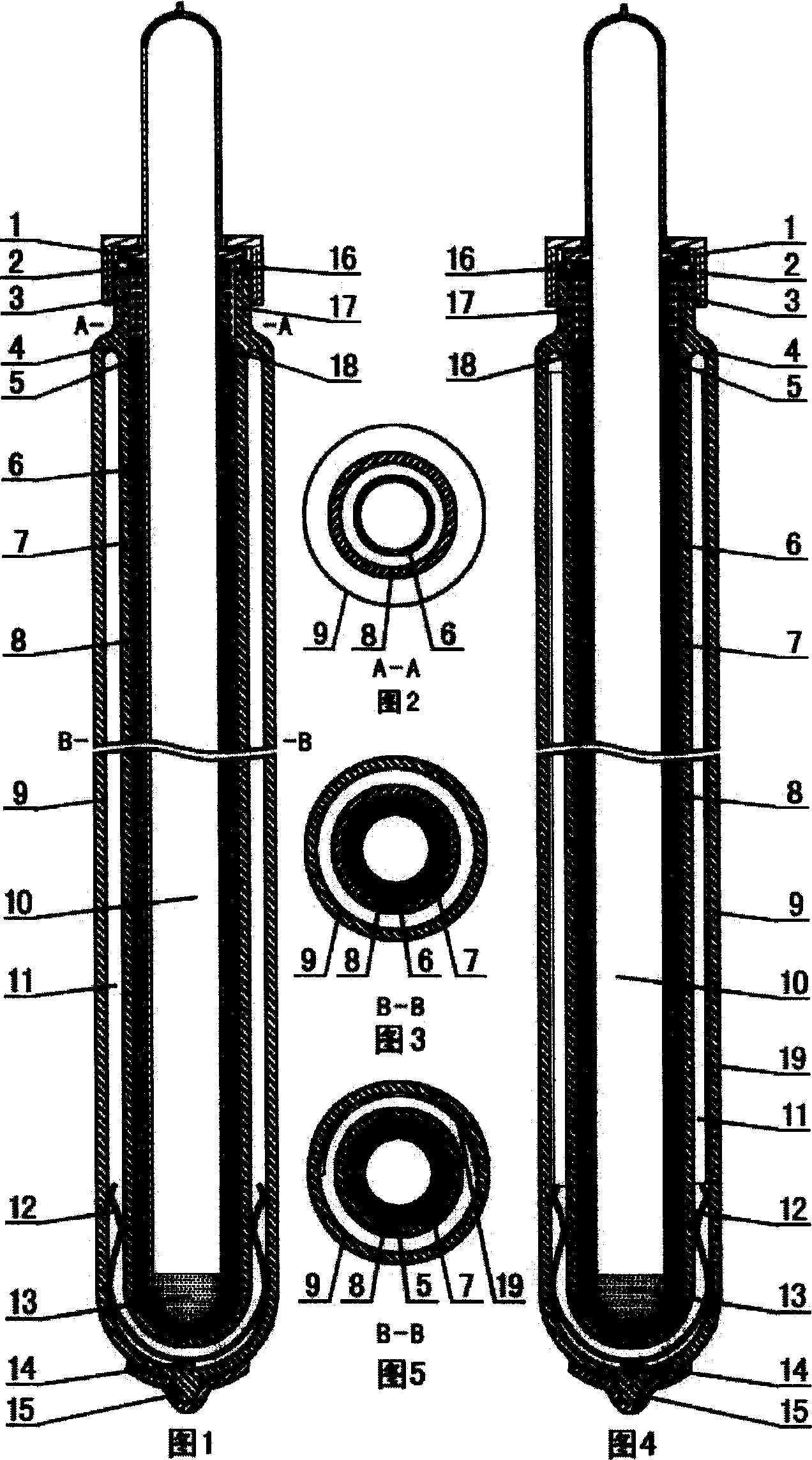

[0044] In the first embodiment: a medium light-to-heat conversion conduction glass composite tube under pressure solar vacuum energy conversion heat pipe includes a reduced diameter nozzle 17, a reduced diameter curved surface transition tube 4, a small diameter inner glass tube 8, an outer glass tube 9, Elastic metal support card 12, air getter 14, exhaust nozzle 15, pressure heat pipe 6, heat conduction material 7, small diameter inner glass tube 8 and outer glass tube 9, variable diameter curved surface transition tube 4, reduced diameter nozzle 17 Annular welding, exhaust nozzle 15 is vacuumed and sealed to form an annular heat-insulating vacuum chamber 11, and the elastic metal support card 12 is set on the small diameter inner glass tube 8, and the getter mirror surface is produced by evaporation of the getter 14, so that the sun The adiabatic vacuum cavity 11 of the vacuum transducing heat pipe is high vacuum. After vacuuming, the pressure-bearing heat pipe 6 filled wit...

no. 5 example

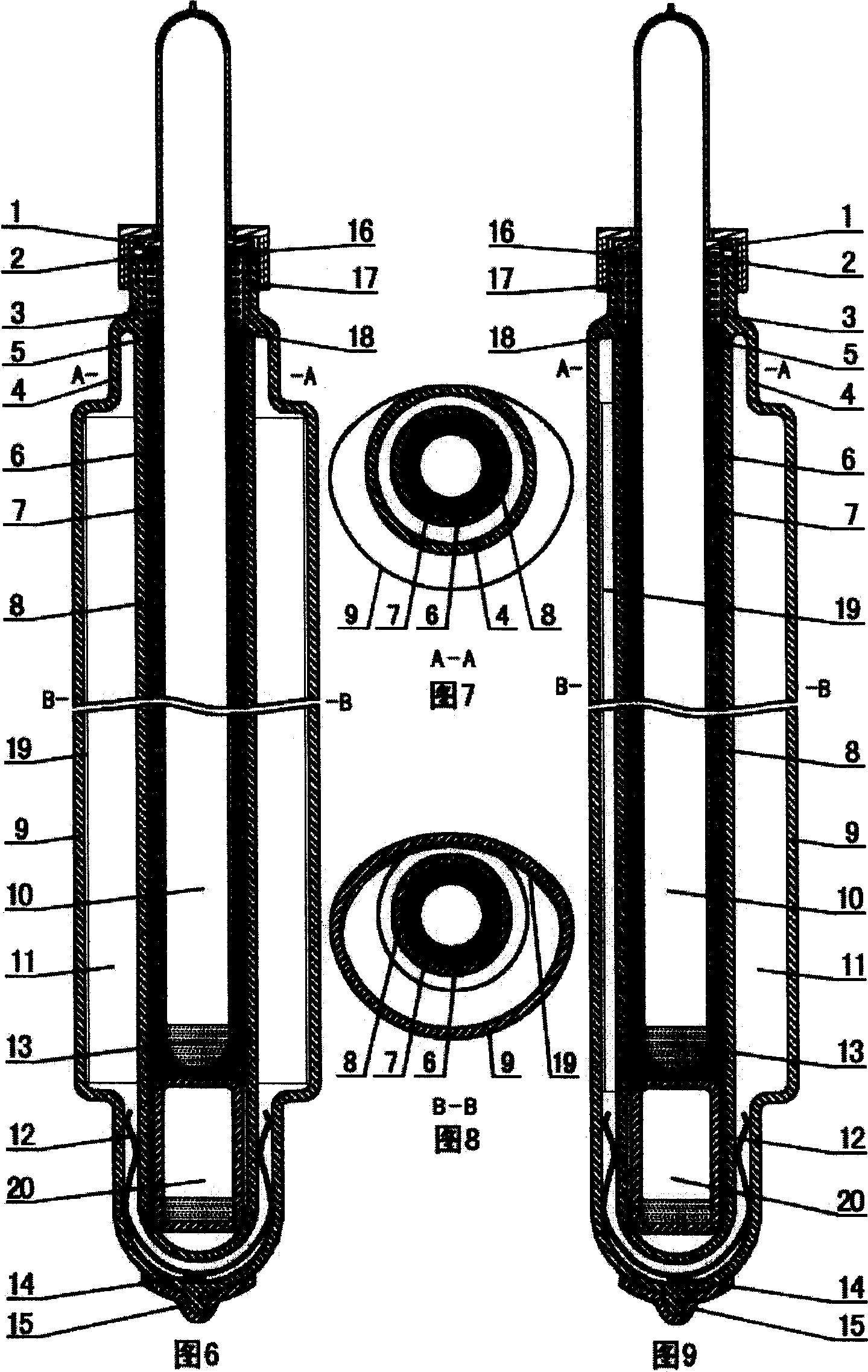

[0048] In the fifth embodiment: the solar vacuum transducer tube is inserted with a concentrating mirror 19, and the others are equal to the second embodiment.

[0049] In the sixth embodiment: there are two supporting pressure heating tubes 6 installed in the solar vacuum transducer tube, and a filling tube 21 is built in the cavity of the solar vacuum transducer tube. Others are equivalent to the third embodiment.

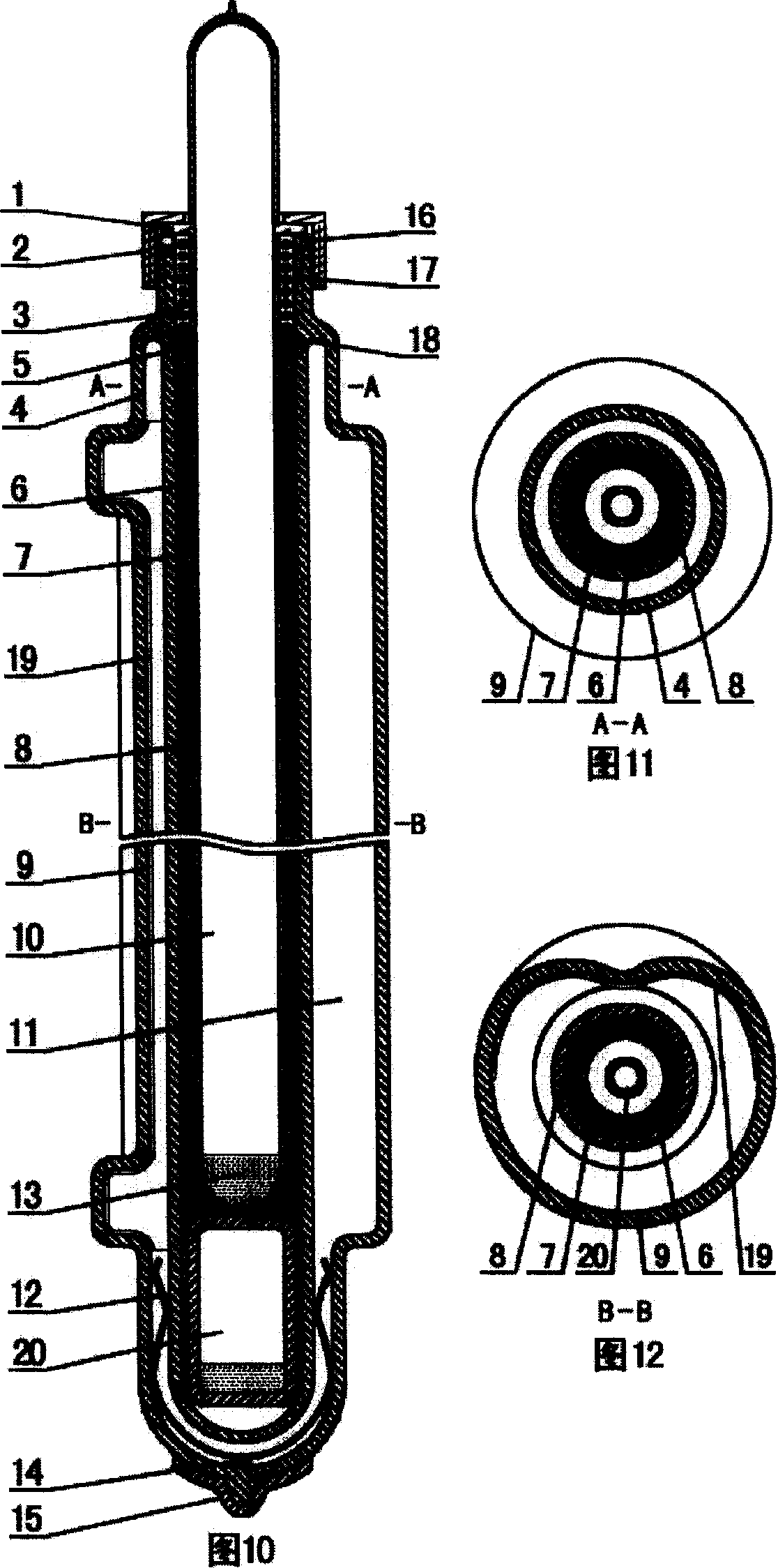

[0050] In the seventh embodiment: the pressure-bearing heat pipe 6 of the medium-conducting glass composite tube bearing the pressure of the solar vacuum energy-transfer heat pipe is compositely connected to the header 22 , and connected to the reduced-diameter nozzle 17 through the sealing nut 2 . Others are the same as the first embodiment.

[0051] In the ninth embodiment: the end cap of the pressure-bearing solar vacuum heat exchange heat pipe of the dielectric conduction glass composite tube is compositely connected to the header, and is connected to the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com