Indicator capable of rapidly determining steam boiler feedwater hardness

A steam boiler and rapid measurement technology, which is applied in the direction of analysis using chemical indicators, can solve the problems of complex process, easy failure, cumbersome production process, etc., and achieve the effect of simple production process, low raw material cost, and fast and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

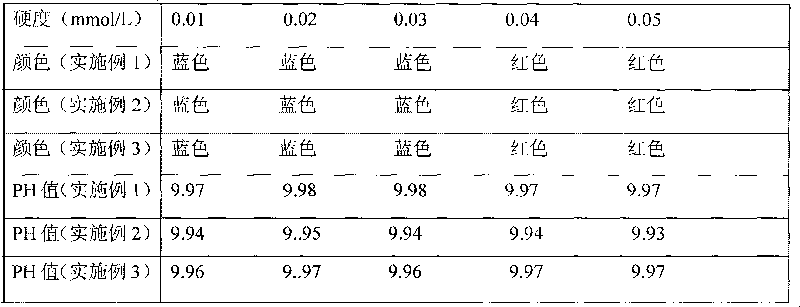

[0015] Example 1: Prepare 100 g of an indicator suitable for detecting the hardness of steam boiler feed water. The raw materials used are all analytical reagents. Sodium chloride 52g, sodium carbonate 19g, sodium bicarbonate 28.7g, edetate disodium 0.13g, chrome black T 0.17g.

Embodiment 2

[0016] Example 2: Prepare 100 g of an indicator suitable for detecting the hardness of steam boiler feed water. The raw materials used are analytical reagents: 57g of sodium chloride, 15g of sodium carbonate, 27.65g of sodium bicarbonate, 0.15g of disodium edetate, and 0.20g of chrome black T.

Embodiment 3

[0017] Embodiment 3: Prepare 100 g of indicators suitable for detecting the hardness of steam boiler feed water. The raw materials used are analytical reagents: 53g of sodium chloride, 18.1g of sodium carbonate, 28.6g of sodium bicarbonate, 0.13g of disodium edetate, and 0.17g of chrome black T.

[0018] The preparation process is as follows:

[0019] Each component of the above weight is put into a vibratory pulverizer, pulverized and mixed in the vibratory pulverizer. After crushing for a certain period of time, take out a 100-mesh sieve, and make a light gray powdery substance, which is the product.

[0020] The method for using the above-mentioned indicator for determining the hardness of steam boiler feed water is: use a graduated cylinder to measure 100ml of demineralized water entering the boiler, and put it into a conical flask. Add 0.5g of indicator (during specific operation, use a teaspoon to take one level spoon of the indicator, the teaspoon is pre-made, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com