Visual welding seam surface quality detection sensor based on line structure light

A technology for detecting sensors and weld surfaces, applied in the direction of optical testing flaws/defects, etc., can solve the problems of inability to detect the width of welds of equal-thickness butt plates, low cost, high price, etc., and achieves time-saving and labor-saving detection tasks. Low cost and the effect of improving the level of autonomy and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

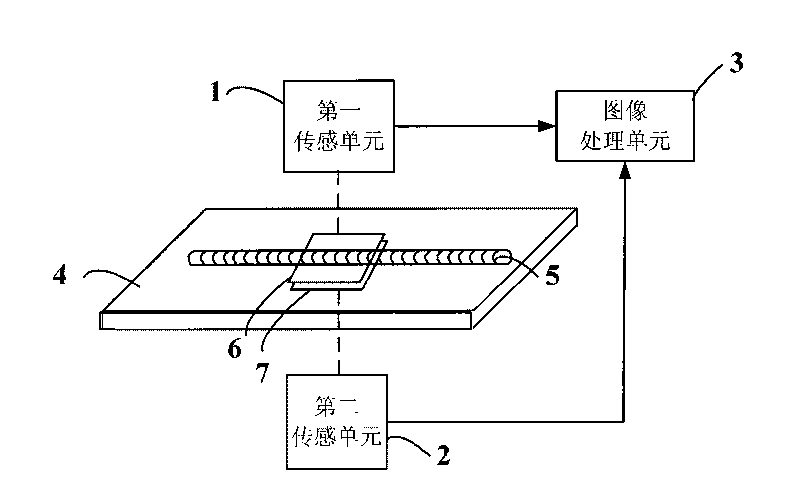

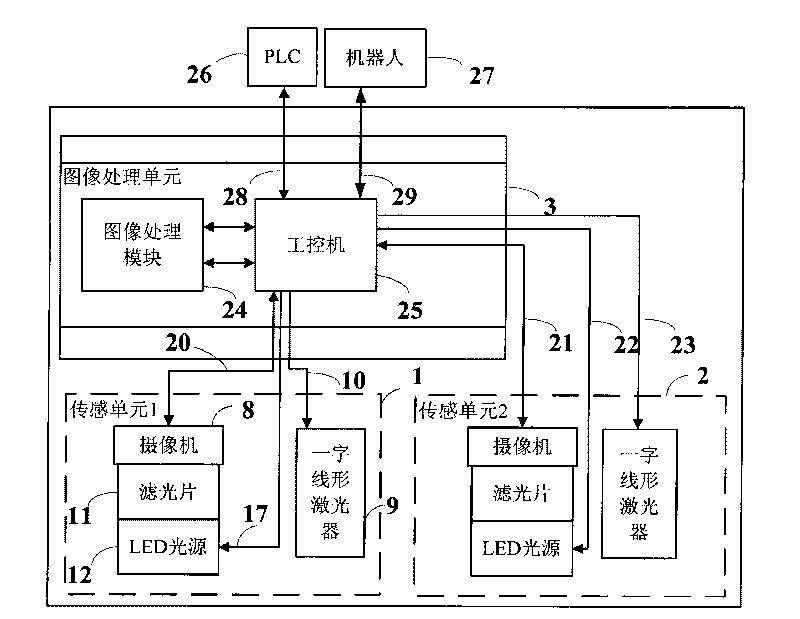

[0027] Such as figure 1 Shown is a schematic diagram of the composition of the welding seam quality detection sensor of the present invention, the sensor is composed of two sensing units (first to second sensing units 1 to 2) and an image processing unit 3 . The two sensing units are respectively located on both sides of the upper and lower surfaces of the weld 5 and are perpendicular to the two surfaces of the welding workpiece 4 . The sensing unit is electrically connected to the processing unit 3 .

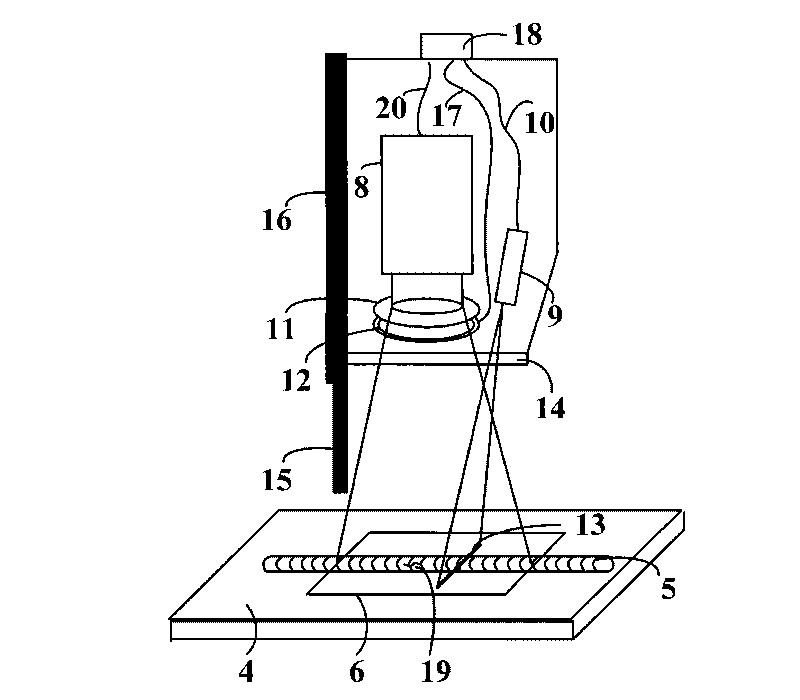

[0028] figure 2 It is a structural schematic diagram of the weld seam quality detection sensing unit of the present invention. The two sensing units have the same structure, and the structural description of one of the sensing units is taken as an example below. The sensing unit includes a camera 8, at least one inline laser 9, an LED ring light source 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com