Method for enriching thianaphthene from mixtures containing thianaphthene and naphthalene

A technology of mixture and thiane, applied in the direction of organic chemistry, can solve the problem of insufficient enrichment efficiency of thiane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

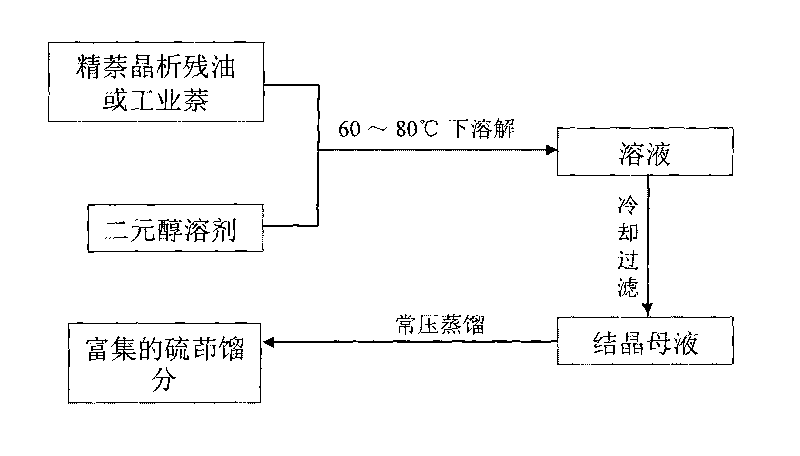

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 200 grams of refined naphthalene crystallization residual oil containing 8.08% of thioindenes and 71.16% of naphthalene in 200 grams of 1,3-butanediol at 60° C., and stir to form a solution. The solution is then naturally cooled to 20°C to crystallize naphthalene and other impurities. Then, the solution is filtered to separate crystals obtained by crystallization, and the obtained filtrate is crystallization mother liquor. Finally, the crystallization mother liquor was distilled to 215° C. to separate 1,3-butanediol to obtain 32.23 g of enriched thiabene fractions. The content of thiabene was 20.18% according to gas chromatography. Obviously, thiabene was effectively enriched.

[0021] (The naphthalene fraction obtained after the distillation of coal tar is industrial naphthalene. Industrial naphthalene is melted and crystallized step by step to prepare a refined naphthalene product with a naphthalene content of more than 99%, and the rest is the refined naphth...

Embodiment 2

[0026] Dissolve 200 grams of refined naphthalene crystallization residual oil containing 8.08% of thioindenes and 71.16% of naphthalene in 400 grams of 1,3-butanediol at 60° C., and stir to form a solution. The solution is then naturally cooled to 20°C to crystallize naphthalene and other impurities. Then, the solution is filtered to separate crystals obtained by crystallization, and the obtained filtrate is crystallization mother liquor. Finally, the crystallization mother liquor was distilled to 215° C. to separate 1,3-butanediol to obtain 46.73 g of enriched thiabene fractions. The thiabene content was 18.06% according to gas chromatography, obviously thiabene was effectively enriched.

[0027] Comparative experiment 2:

[0028] Dissolve 200 grams of refined naphthalene crystallization residual oil containing 8.08% of thioindenes and 71.16% of naphthalene in 400 grams of ethanol at 60° C., and stir to form a solution. Then the solution was naturally cooled to 20°C to crys...

Embodiment 3

[0031] Dissolve 200 grams of refined naphthalene crystallization residual oil containing 8.08% of thioindenes and 71.16% of naphthalene in 100 grams of 1,3-butanediol at 65° C., and stir to form a solution. The solution is then naturally cooled to 20°C to crystallize naphthalene and other impurities. Then, the solution is filtered to separate crystals obtained by crystallization, and the obtained filtrate is crystallization mother liquor. Finally, the crystallization mother liquor was distilled to 215° C. to separate 1,3-butanediol to obtain 18.54 g of enriched thiabene fractions. According to gas chromatography analysis, the thiabene content was 24.43%. Obviously, thiabene was effectively enriched.

[0032] Comparative experiment 3:

[0033] Dissolve 200 grams of refined naphthalene crystallization residual oil containing 8.08% of thioindenes and 71.16% of naphthalene in 100 grams of ethanol at 65° C., and stir to form a solution. Then the solution was naturally cooled to 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com