Method for synthesizing 1-chloroformyl-3-methyl sulfonyl-2-imidazo flavanone

A technology of imidazolidinone and methylsulfonyl, which is applied in the field of synthesis of pharmaceutical intermediates, and can solve the problems of waste of time and raw materials, production constraints, and low reaction yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

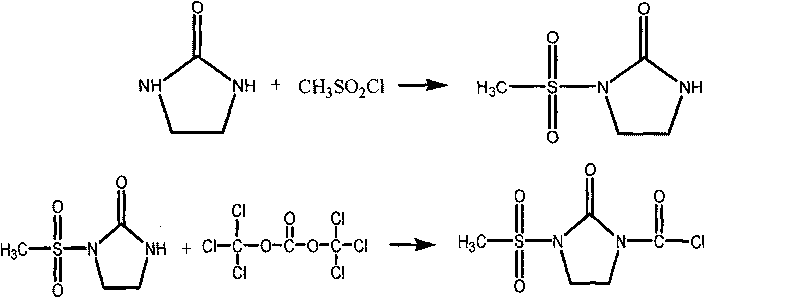

Method used

Image

Examples

Embodiment 1

[0030] Step (1): Preparation of methylsulfonyl-2-imidazolidinone:

[0031] The molar ratio of feeding is 2-imidazolidinone:methanesulfonyl chloride:triethylamine=1:1.2:0.1.

[0032] Add 2-imidazolidinone and methanesulfonyl chloride into the reaction kettle and stir, react at 10°C for 1h, then heat up to 90°C, when solid matter appears, add catalyst triethylamine, continue to react for 1h, add water, and heat up to All the solid matter was dissolved, cooled to 10°C, suction filtered, washed with water, and dried to obtain the product methanesulfonyl-2-imidazolidinone with a yield of 76%, a melting point of 190.3-190.8°C, a content of 98.6% (HPLC), and a purity of 99.1 %.

[0033] Step (2): Preparation of 1-chloroformyl-3-methylsulfonyl-2-imidazolidinone:

[0034] The molar ratio of feeding is methanesulfonyl-2-imidazolidinone: triphosgene: triethylamine=1:0.4:0.4

[0035] The amount of solvent used: methanesulfonyl-2-imidazolidinone: dichloromethane = 1 g: 5 ml.

[0036] A...

Embodiment 2

[0038] Step (1): Preparation of methylsulfonyl-2-imidazolidinone:

[0039] The molar ratio of feeding is 2-imidazolidinone:methylsulfonyl chloride:pyridine=1:1.2:0.1.

[0040] Add 2-imidazolidinone and methanesulfonyl chloride into the reaction kettle and stir, react at 10°C for 1h, then heat up to 90°C, when solid matter appears, add catalyst pyridine, continue to react for 1h, add water, heat up to solid matter All dissolved, cooled to 10°C, suction filtered, washed with water, and dried to obtain the product methanesulfonyl-2-imidazolidinone with a yield of 80%, a melting point of 190.4-191.0°C, a content of 98.8% (HPLC), and a purity of 99.0%.

[0041] Step (2): Preparation of 1-chloroformyl-3-methylsulfonyl-2-imidazolidinone:

[0042] The molar ratio of feeding is methanesulfonyl-2-imidazolidinone:triphosgene:triethylamine=1:0.4:0.4.

[0043] The consumption of solvent: methylsulfonyl-2-imidazolidinone: dichloromethane=1g: 10ml

[0044] Add the methanesulfonyl-2-imidaz...

Embodiment 3

[0046] Step (1): Preparation of methylsulfonyl-2-imidazolidinone:

[0047] The feeding molar ratio is 2-imidazolidinone: methylsulfonyl chloride: N, N-dimethylformamide = 1: 1.2: 0.1

[0048] Add 2-imidazolidinone and methanesulfonyl chloride into the reaction kettle and stir, react at 10°C for 1 hour, then heat up to 90°C, when solid matter appears, add catalyst N,N-dimethylformamide to continue the reaction 1h, add water, heat up until the solid matter is completely dissolved, cool down to 10°C, filter with suction, wash with water, and dry to obtain the product methanesulfonyl-2-imidazolidinone with a yield of 78%, a melting point of 190.0-190.5°C, and a content of 98.4% (HPLC), 99.3% pure.

[0049] Step (2): Preparation of 1-chloroformyl-3-methylsulfonyl-2-imidazolidinone:

[0050] The molar ratio of feeding is methanesulfonyl-2-imidazolidinone:triphosgene:triethylamine=1:0.4:0.4.

[0051] The consumption of solvent: methylsulfonyl-2-imidazolidinone: dichloromethane=1g:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com