Dewatering sludge alkaline type semi-desiccation processing method of sewage treatment plants

A sewage treatment plant, dewatered sludge technology, applied in the direction of dewatering/drying/concentrated sludge treatment, etc., can solve the limitation of the popularization and application of sludge thermal drying technology, the difficulty in controlling leachate and odor, and the volume of drying device. huge problems, so as to achieve social and economic benefits, reduce the total number of coliform bacteria and bacteria, and achieve good economic results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

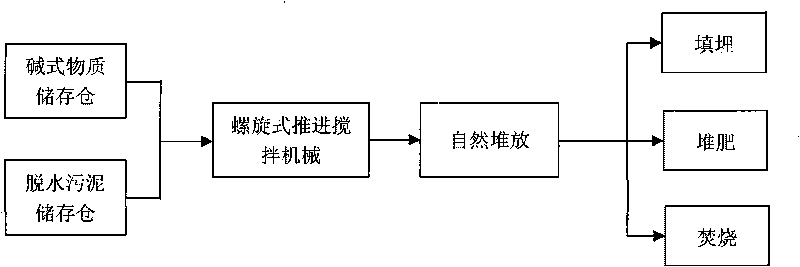

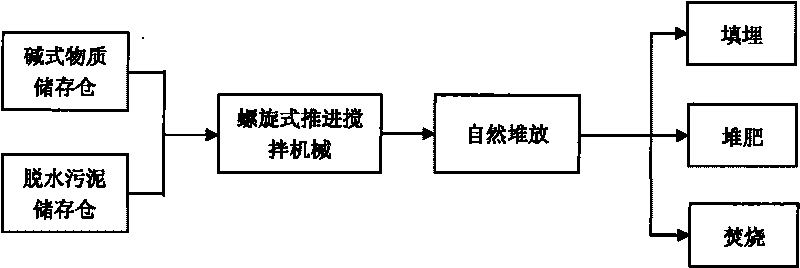

[0029] A method for alkaline semi-dry treatment of dewatered sludge in a sewage treatment plant. The steps of the method are as follows. Lime is selected as the alkaline material, and the dewatered sludge is treated by the activated sludge method. The water content is 84.38%. Mud = 0.02:1 ratio Put lime and dewatered sludge into a spiral propulsion mixer, stir for 30 minutes, stir evenly, and stack naturally for 7 days to obtain treated sludge.

[0030] The moisture content of the treated sludge is reduced to 40.01% on the 7th day, which can meet the water demand for the sludge to be filled in domestic waste landfill or composted. Compared with other heating and drying methods, it can save 5 to 10 times the cost to achieve the same effect.

Embodiment 2

[0032] A method for alkaline semi-dry treatment of dewatered sludge in a sewage treatment plant. The steps of the method are as follows. Lime is selected as the alkaline material, and the dewatered sludge is treated by the activated sludge method. The water content is 84.72%. Mud = 0.1:1 ratio Put lime and dewatered sludge into a spiral propulsion mixer, stir for 25 minutes, stir evenly, and stack naturally for 7 days to obtain treated sludge.

[0033] The moisture content of the treated sludge is reduced to 32.25% on the 7th day, which can meet the water demand of the sludge entering the domestic waste landfill for landfill, incineration, composting and other disposal. Compared with other heating and drying methods, it can save 4 to 9 times the cost to achieve the same effect.

Embodiment 3

[0035] A method for alkaline semi-drying treatment of dewatered sludge in a sewage treatment plant. The steps of the method are as follows. The alkaline material is selected from fly ash, and the dewatered sludge is treated by activated sludge method. The water content is 81.91%. According to the weight ratio of fly ash: Dewatered sludge = 0.05:1 ratio Put fly ash and dewatered sludge into a spiral propulsion mixer, stir for 30 minutes, stir evenly, stack naturally for 7 days, and obtain treated sludge.

[0036] The moisture content of the treated sludge was reduced to 40.34% on the 7th day, which can meet the water demand of the sludge to be landfilled or incinerated, composted, etc. in the domestic waste landfill. Because fly ash is waste from incineration plants, compared with other heating and drying methods, it can save 10 to 13 times the cost to achieve the same effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com