Method for calibrating empty roll gap of sheet and strip cold-rolling mill

A cold rolling mill, plate and strip material technology, applied in the field of empty roll gap roll correction, can solve the problems of oil film bearing burnout, rolling mill strip breakage, stacking steel, etc., to prevent rolling mill strip breakage, avoid roll system tilting, and ensure normal operation The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

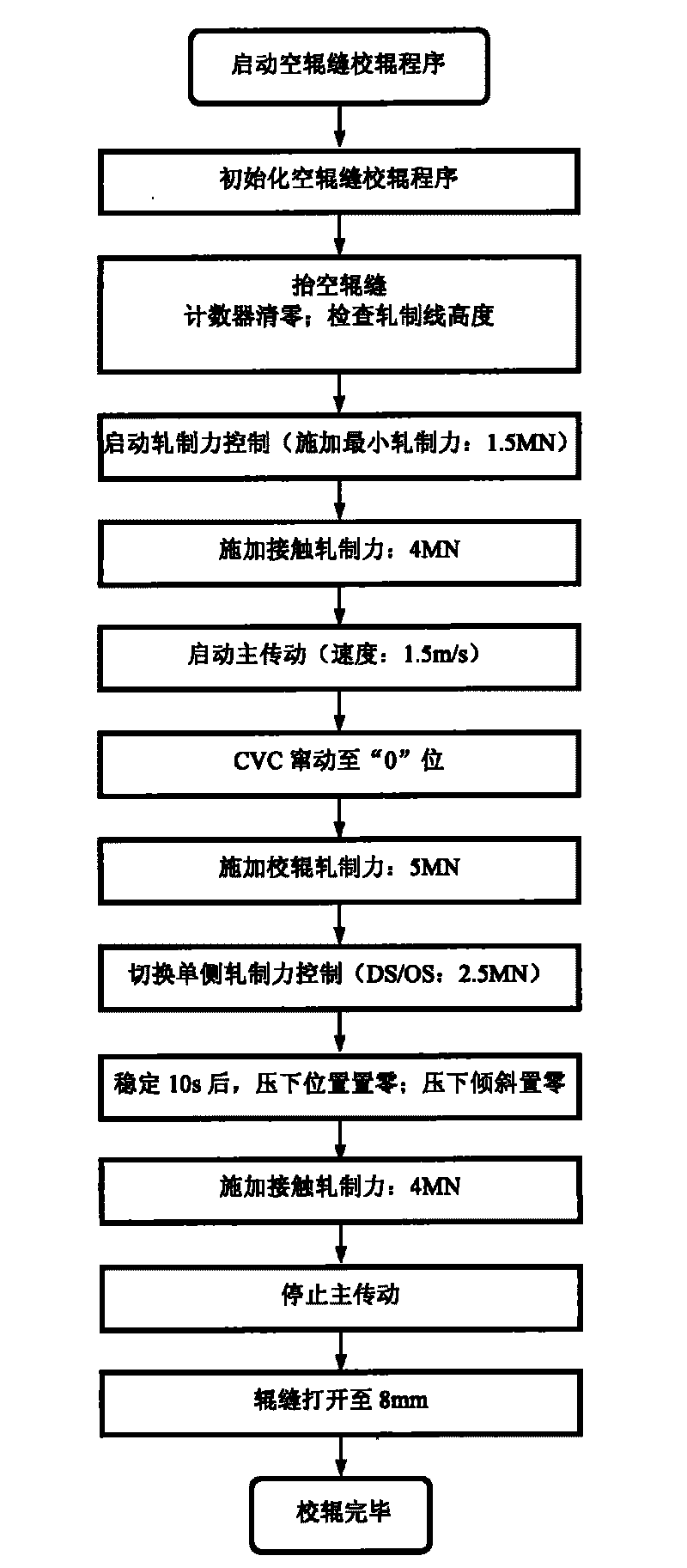

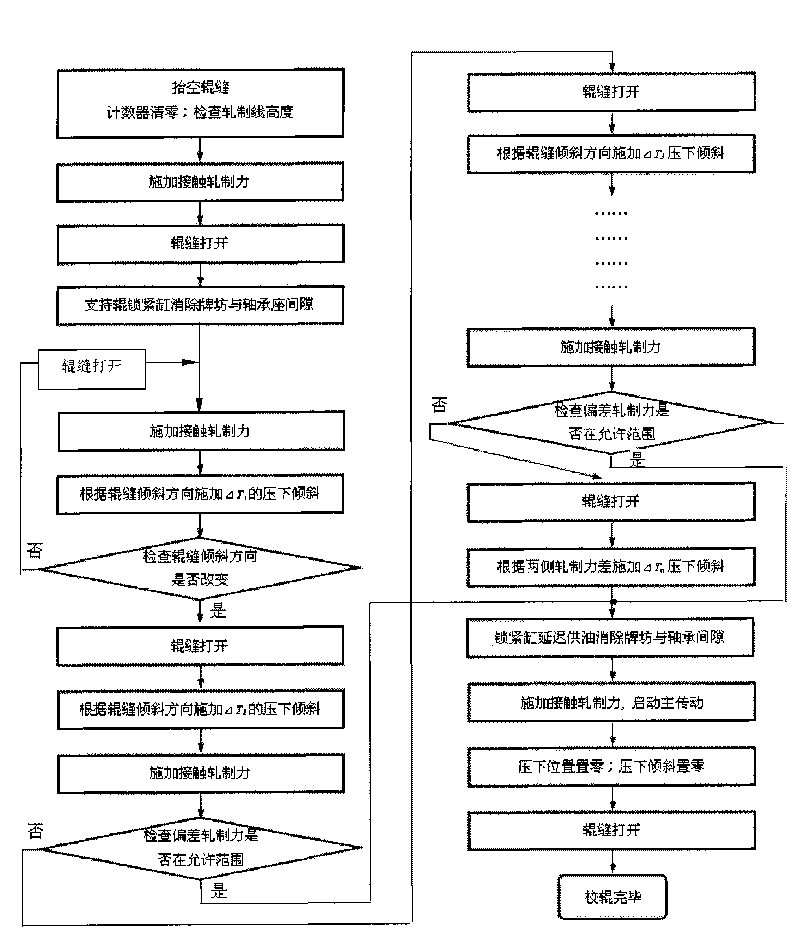

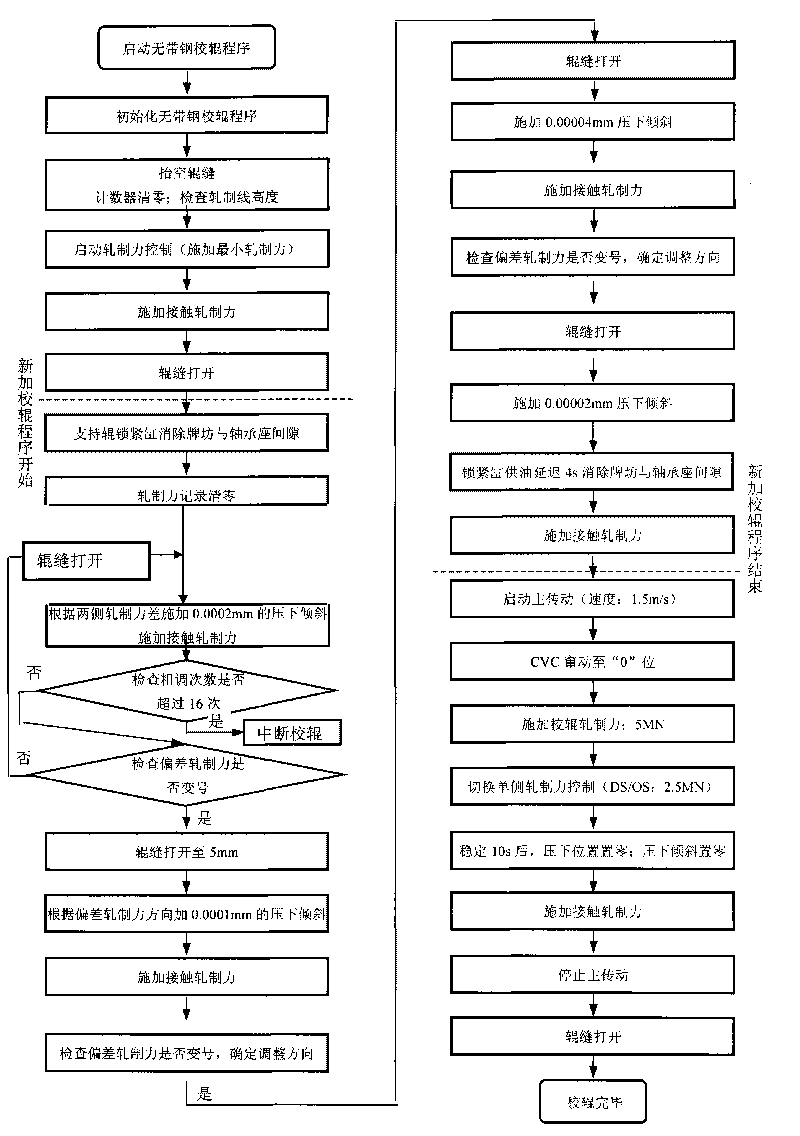

[0053] Three preferred implementation modes of the present invention will be introduced below using the empty roll gap calibration method of the plate and strip cold rolling mill of the present invention on three 1420 continuous cold rolling mills (S1, S2, S3) as an example.

[0054] Set the contact rolling force of 1420 cold tandem rolling mill to 4MN during the whole roll calibration process. In the process of coarse adjustment, apply a 0.0002mm depression inclination on the zero position of the depression during each adjustment process, and the coarse adjustment process can be adjusted up to 16 times. Racks S1, S2, and S3 changed their inclination directions after the second, fourth, and eighth rough adjustments, respectively. The fine adjustment process is set up to three adjustments, and the applied depressing inclinations are 0.0001mm, 0.00004mm and 0.00002mm respectively.

[0055] Roll calibration process of S1 rack:

[0056] Step 1.1 Lift the rack to the top and clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com