Method for inhibiting non-specific adsorption of solid material surface

A solid material, non-specific technology, applied in the direction of surface coating liquid devices, special surfaces, material inspection products, etc., can solve the problems of reducing non-specific adsorption of biomolecules, adsorption reduction, complex structure, etc., to achieve rapid preparation, The effect of easy operation and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

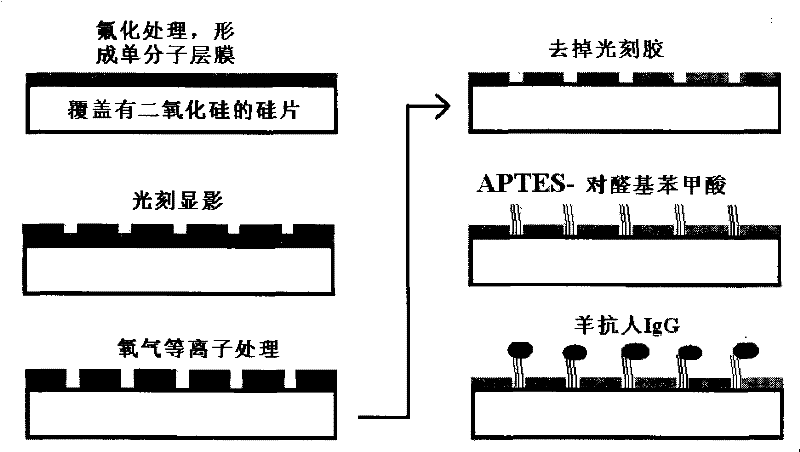

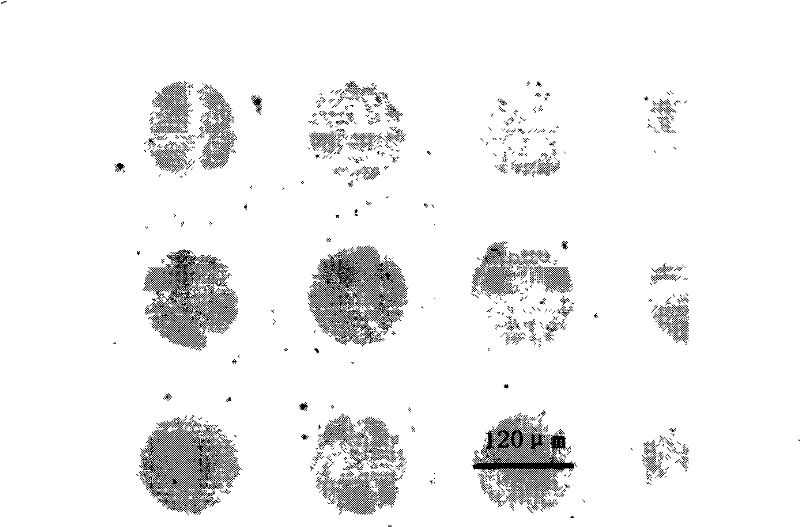

[0027] After 15 single crystal silicon wafers with silicon dioxide grown on the surface were cleaned with absolute ethanol and deionized water, the surface was cleaned in an oxygen plasma cleaner for 0.5 minutes to completely remove organic dirt. At 80°C, the wafers were divided into 5 groups and placed in perfluoropropyltriethoxysilane [CF 3 (CF 2 ) 2 Si(OCH 2 CH 3 ) 3 ], 1,1,2,2-tetrahydroperfluorohexyltriethoxysilane [CF 3 (CF 2 ) 3 (CH 2 ) 2 Si(OCH 2 CH 3 ) 3 ], 1,1,2,2,3,3,4,4,5,5-decahydroperfluorohexadecyltriethoxysilane [CF 3 (CF 2 ) 10 (CH 2 ) 5 Si(OCH 2 CH 3 ) 3 ], 1,1,2,2-tetrahydroperfluorooctylmethoxy-diethoxysilane [CF 3 (CF 2 ) 5 (CH 2 ) 2 SiOCH 3 (OCH 2 CH 3 ) 2 ], 1,1,2,2-tetrahydroperfluorooctyldiethoxychlorosilane [CF 3 (CF 2 ) 5 (CH 2 ) 2 Si(OCH 2 CH 3 ) 2 Cl] in the gas phase atmosphere for 24 hours, after taking it out, use absolute ethanol to clean the surface, and dry it with nitrogen flow for later use. Through the ...

Embodiment 2

[0029] After cleaning 15 monocrystalline silicon wafers with silicon dioxide grown on the surface with absolute ethanol and deionized water, the surface was cleaned in an oxygen plasma cleaner for 3 minutes to completely remove organic dirt. At 150°C, the wafers were divided into 5 groups and placed in perfluoropropyltrimethoxysilane [CF 3 (CF 2 ) 2 Si(OCH 3 ) 3 ], 1,1,2,2-tetrahydroperfluorohexylmethoxysilane [CF 3 (CF 2 ) 3 (CH 2 ) 2 Si(OCH 3 ) 3 ], 1,1,2,2,3,3,4,4,5,5-decahydroperfluorohexadecylmethoxysilane [CF 3 (CF 2 ) 10 (CH 2 ) 5 Si(OCH 3 ) 3 ], 1,1,2,2-tetrahydroperfluorooctyldimethoxychlorosilane [CF 3 (CF 2 ) 5 (CH 2 ) 2 Si(OCH 3 ) 2 Cl], 1,1,2,2-tetrahydroperfluorooctyldimethoxyisocyanosilane [CF 3 (CF 2 ) 5 (CH 2 ) 2 Si(OCH 3 ) 2 CNO] in the gas phase atmosphere for 10 seconds, after taking it out, use absolute ethanol to clean the surface, and blow dry with nitrogen flow for later use. Through the above method, a layer of fluorinate...

Embodiment 3

[0031] After cleaning 15 monocrystalline silicon wafers with silicon dioxide grown on the surface with absolute ethanol and deionized water, the surface was cleaned in an oxygen plasma cleaner for 3 minutes to completely remove organic dirt. At 150°C, the wafers were divided into 5 groups and placed in perfluoropropyltrichlorosilane [CF 3 (CF 2 ) 2 SiCl 3 ], 1,1,2,2-tetrahydroperfluorohexyltrichlorosilane [CF 3 (CF 2 ) 7 (CH 2 ) 2 SiCl 3 ], 1,1,2,2,3,3,4,4,5,5-decahydroperfluorohexadecyltrichlorosilane [CF 3 (CF 2 ) 10 (CH 2 ) 5 SiCl 3 ], 1,1,2,2-tetrahydroperfluorooctylmethoxydichlorosilane [CF 3 (CF 2 ) 5 (CH 2 ) 2 Si(OCH 3 )Cl 2 ], 1,1,2,2-tetrahydroperfluorooctylisocyanodichlorosilane [CF 3 (CF 2 ) 5 (CH 2 ) 2 Si(CNO)Cl 2 ] in the gas phase atmosphere for 10 seconds, after taking it out, use absolute ethanol to clean the surface, and blow dry with nitrogen flow for later use. Through the above method, a layer of fluorinated monomolecular layer fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com