Manufacturing method of shallow trench structure and flash memory

A manufacturing method and technology of shallow trenches, which are applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve problems such as easy damage of filled trenches and degradation of electrical performance of flash memory, so as to improve electrical performance and repair Defects, the effect of improving the stress environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

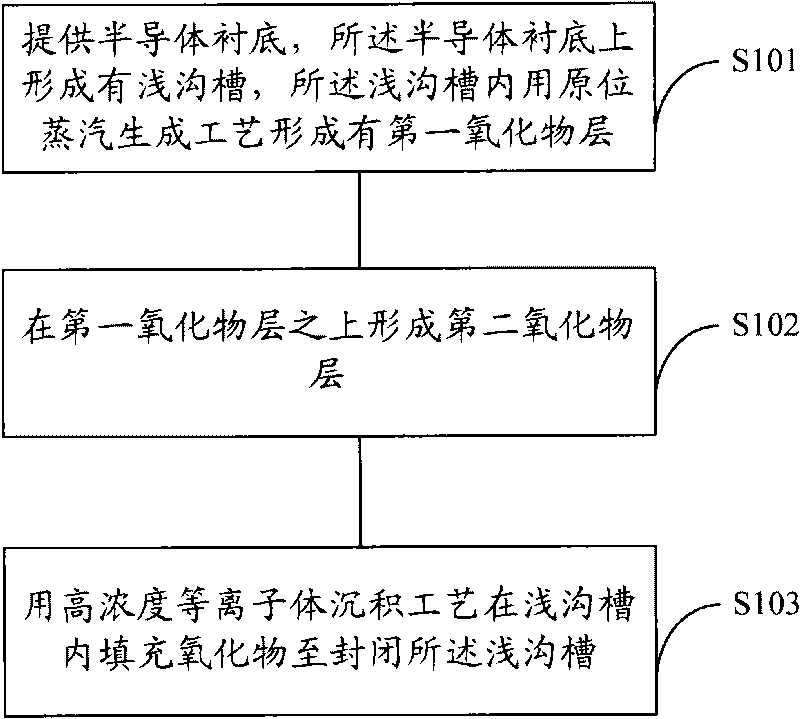

[0020] Narrow Width Effect (Narrow Width Effect) is an important factor affecting the electrical performance of flash memory. The narrow width effect is due to the STI edge geometry, stress, and non-uniform doping distribution along the channel width. These effects have a great influence on the device current, so that the difference of MOS drive current can reach 30%, and the difference of turn-off current can be more than two times.

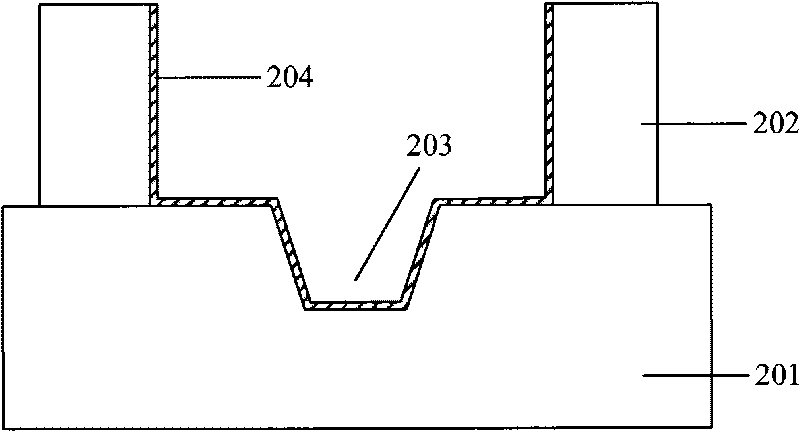

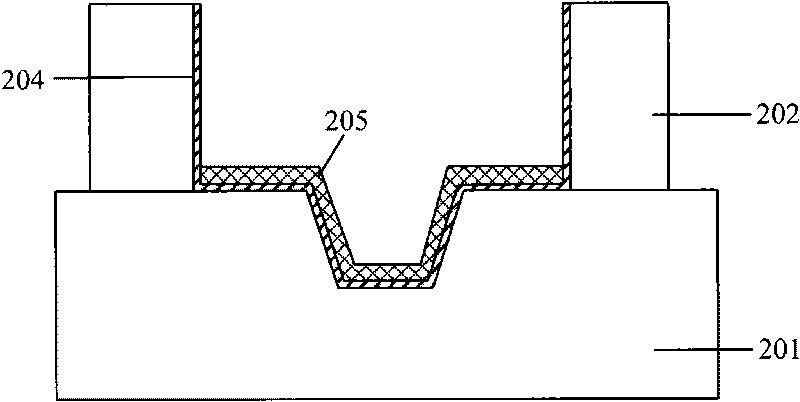

[0021] In order to reduce the narrow width effect, those skilled in the art usually use the ISSG method to form a thin and loose oxide layer in the STI trench of the flash memory structure, that is, the ISSG oxide layer, which is used to repair the substrate crystal in the STI trench. The lattice defects and the improvement of the substrate surface stress in the trench can also protect the substrate surface in the trench and prevent the substrate from being damaged by the subsequent filling process.

[0022] However, when HDP is used to fill th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com