Reaction chamber and semiconductor processing device

A reaction chamber and chamber wall technology, which is applied in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., can solve problems such as the size of the suspended support arm should not be too small, uneven air distribution, and asymmetric air flow path. To achieve the effect of flexible layout, simple structure and uniform air distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

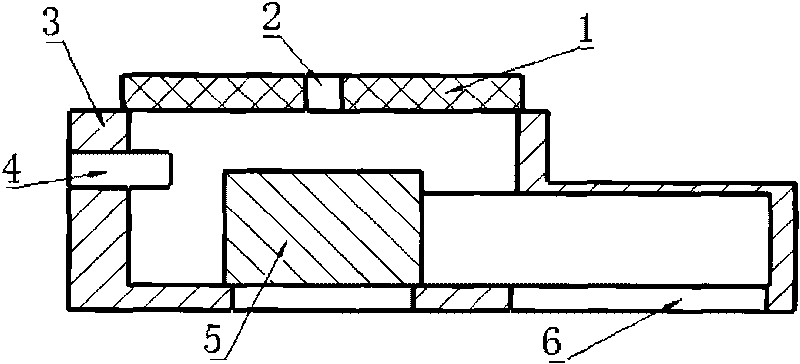

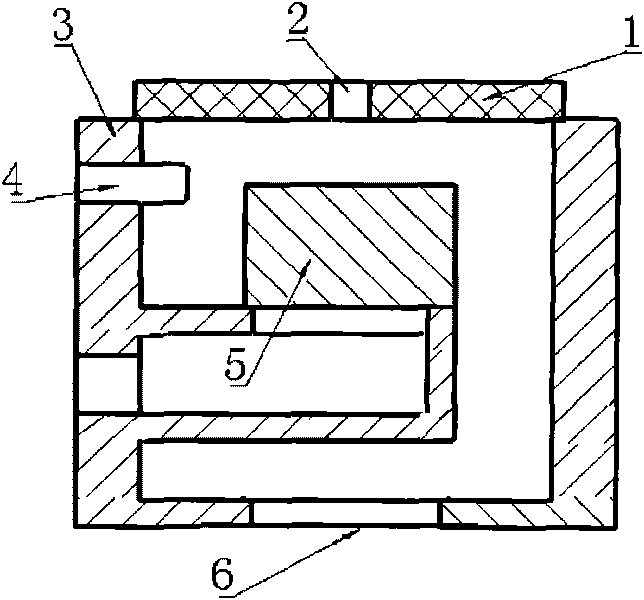

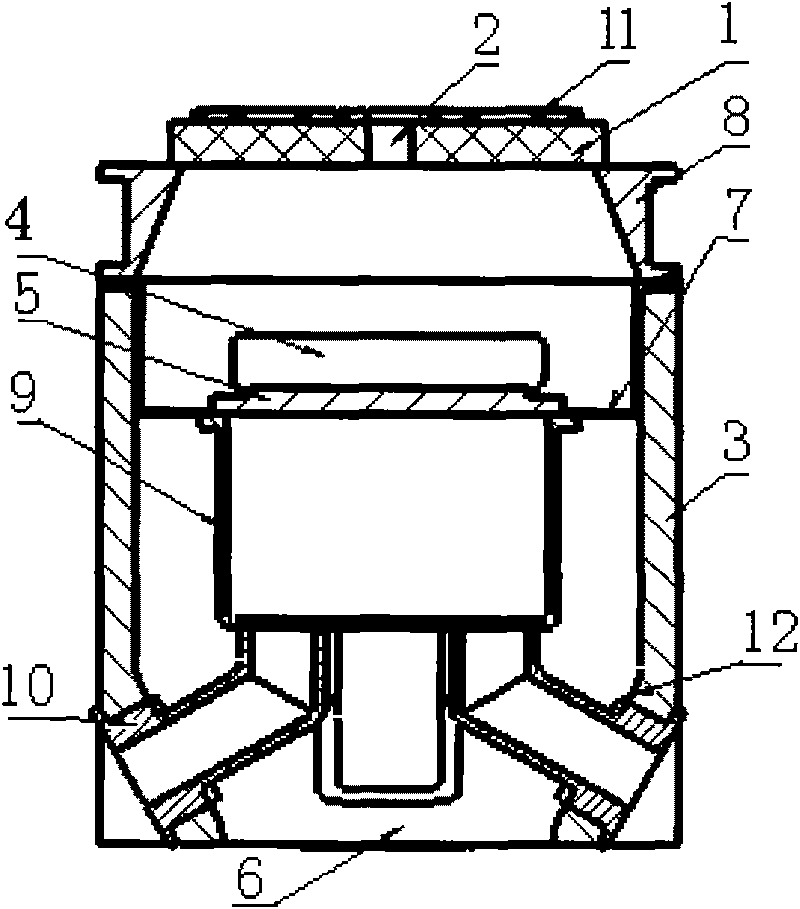

[0026] Reaction chamber of the present invention, its preferred embodiment one, as image 3 As shown, the chamber wall 3 is included, and the inner cavity of the reaction chamber is provided with a lower electrode box body 9, and the lower electrode box body 9 is supported on the chamber wall 3 through a plurality of channels 10, and the lower electrode box body 9 is supported on the chamber wall 3. The inner cavity communicates with the outside of the reaction chamber through a channel 10 ; the lower part of the chamber wall 3 is provided with a suction port 6 .

[0027] There can be 2 to 8 channels 10, such as 3 or 4 channels. A plurality of channels 10 may be evenly distributed circumferentially around the longitudinal axis of the reaction chamber to form a centrally symmetrical arrangement.

[0028] The specific structure can be that the reaction chamber is surrounded by the chamber wall 3, the dielectric window 1 and the dielectric window support 8, etc. to form a vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com