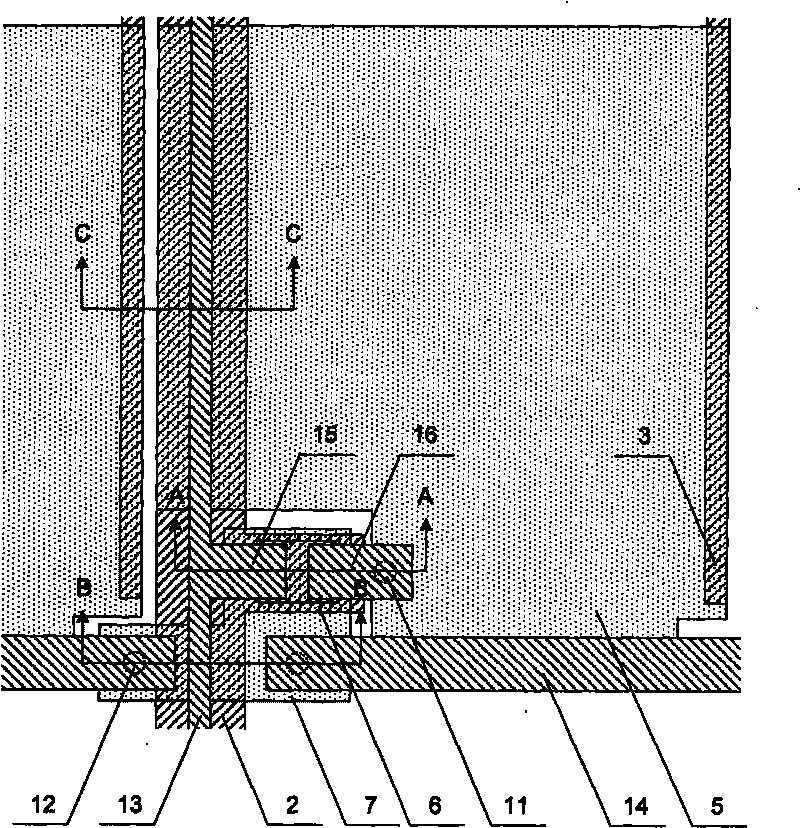

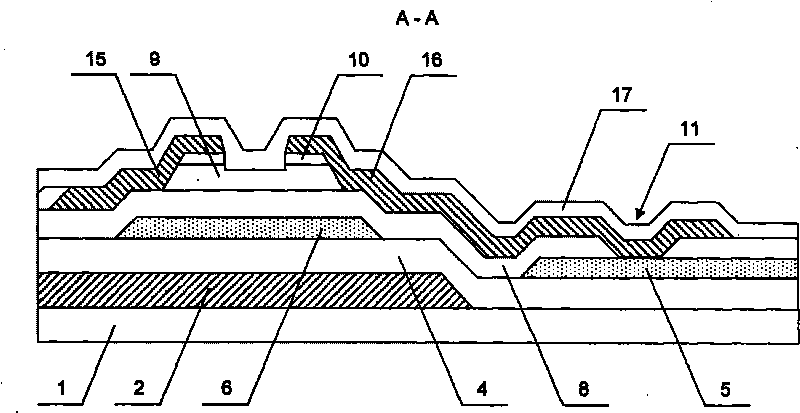

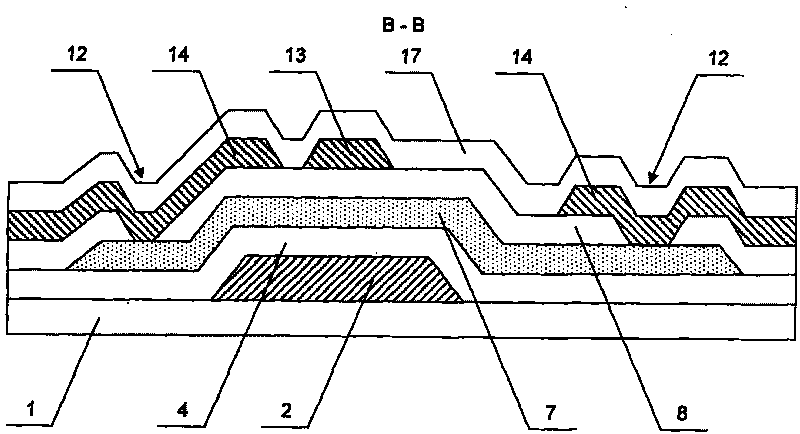

TFT-LCD (thin film transistor-liquid crystal display) array substrate and manufacture method thereof

An array substrate and substrate technology, applied in the field of thin film transistor liquid crystal display structure and its manufacture, can solve the problems of low aperture ratio and small storage capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0069] The five-time patterning process described above is only an implementation method of the TFT-LCD array substrate manufacturing method of the present invention. Under the guiding idea of placing the common electrode line under the data line, it can also be added or reduced in actual use. The number of processes or other processes are used to form the array substrate.

[0070] Figure 26 It is a flow chart of a method for forming an active layer, a first contact via hole and a second contact via pattern in the manufacturing method of the TFT-LCD array substrate of the present invention. exist Figure 25 In the technical solution shown, step 3 specifically includes:

[0071] Step 311, sequentially depositing a gate insulating layer, a semiconductor layer and a doped semiconductor layer on the substrate after step 2;

[0072] Step 312, coating a layer of photoresist;

[0073]Step 313, using a two-tone mask to expose the photoresist, so that the photoresist forms a pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com