Liquid absorbing core for embedded channels of heat pipe

A technology of fitting grooves and heat pipes, used in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of high heat source heating power, inability to meet heat dissipation requirements, and damage to system stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

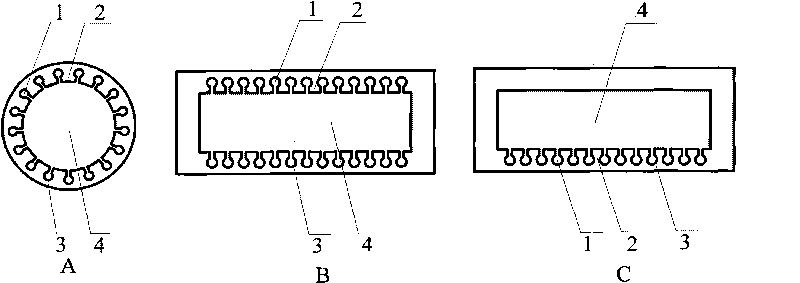

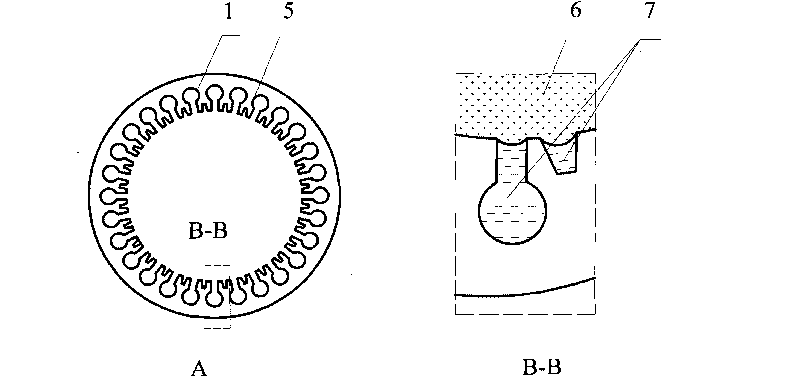

[0047] Carry out further detailed description below in conjunction with accompanying drawing:

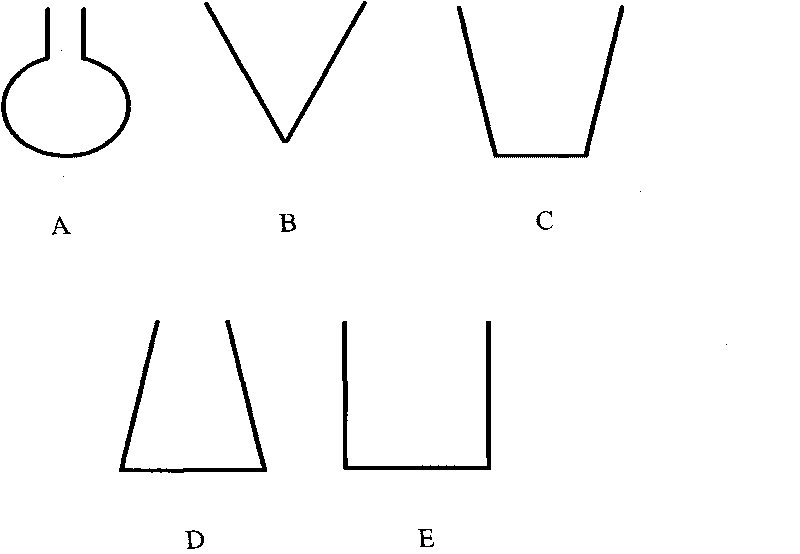

[0048] The working principle of the ordinary channel heat pipe is: in the evaporation section, the working liquid in the channel 1 absorbs the heat of the heat source and undergoes an evaporation phase change. The latent heat released after condensation in the condensation section is taken away by the cold source, and the working liquid flows from the condensation section to the evaporation section under the action of capillary force and gravity, and the condensate returned to the evaporation section evaporates again due to heat absorption, so that the heat source is continuously circulated. The heat is continuously transferred to the cold source. In the evaporation section, such as Figure 4 As shown, the gas-liquid interface can be divided into non-evaporating region, evaporating thin liquid film region and meniscus region. The working liquid evaporates at the entire gas-liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com