Heat exchanger of air conditioner with double rows of pipelines

A double-row tube and heat exchanger technology, applied in evaporator/condenser, lighting and heating equipment, refrigeration components, etc., can solve the problems of low heat exchange efficiency, low energy efficiency, low heat exchange efficiency, etc., to improve Effect of heat transfer coefficient and heat transfer amount, improvement of heat transfer uniformity, and improvement of refrigeration energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

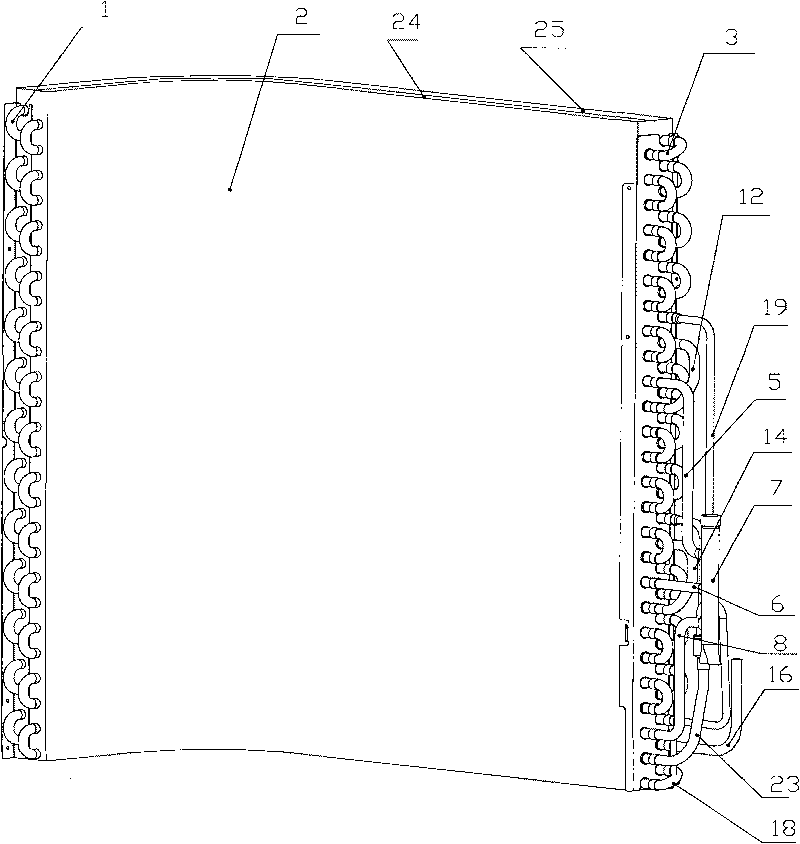

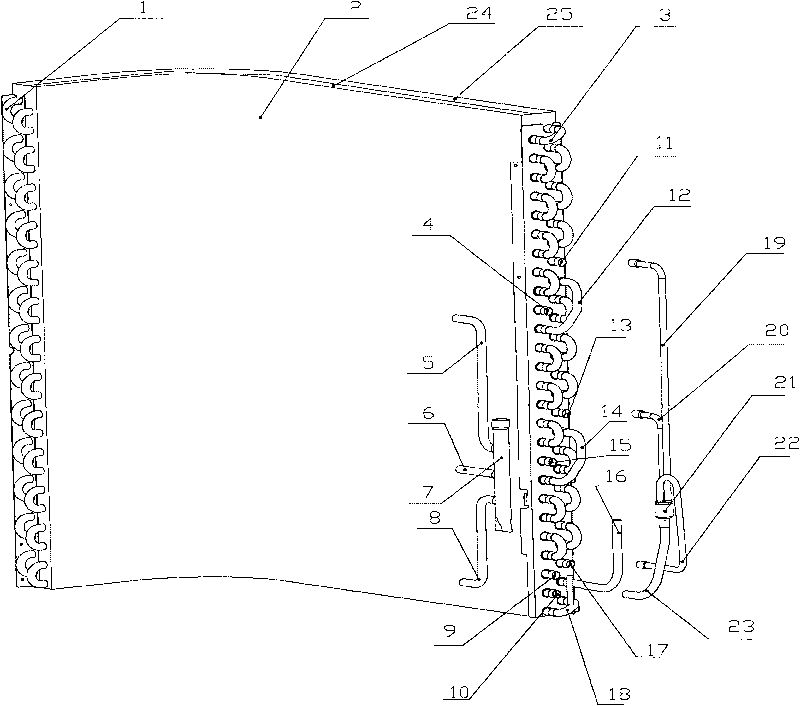

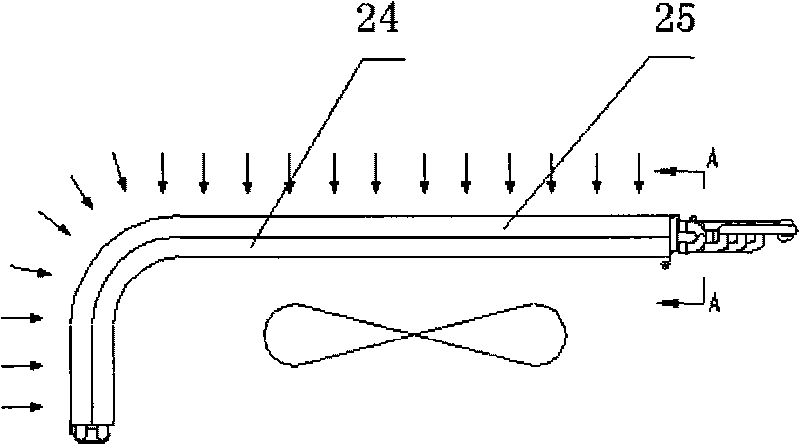

[0017] See attached Figure 1~3 , the double-row tube air-conditioning heat exchanger of the present invention includes fins 2 and double-row condensation pipes 1 passing through the inner cavity of the fins 2, a shunt pipe 7 and a distributor 21 connected to the condensation pipes 1 in the middle and lower parts of the fins 2 , and the connecting pipe 16 located at the bottom of the fin 2 and communicating with the condensing pipe 1, the condensing pipe 1, the shunt pipe 7 and the connecting pipe 16 all adopt copper pipes, and the distributor 21 is a full liquid copper distributor.

[0018] The branch pipe 7 includes the first branch pipe 5, the second branch pipe 6 and the third branch pipe 8 which divide the refrigerant into three paths, the first branch pipe 5 and the first inflow port of the condenser pipe 1 in the upper part of the fin 2 4, the second branch pipe 6 communicates with the second inflow port 15 of the condensation pipe 1 in the middle of the fin 2, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com