Micro-pressure operating adsorption refrigerating system

A technology of adsorption refrigeration and micro-positive pressure, which is applied in the direction of refrigerators, refrigeration and liquefaction, adsorption machines, etc. It can solve the problems of unstable performance and high equipment requirements, and achieve improved safety and stability, low cost, and shortened cycles. cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

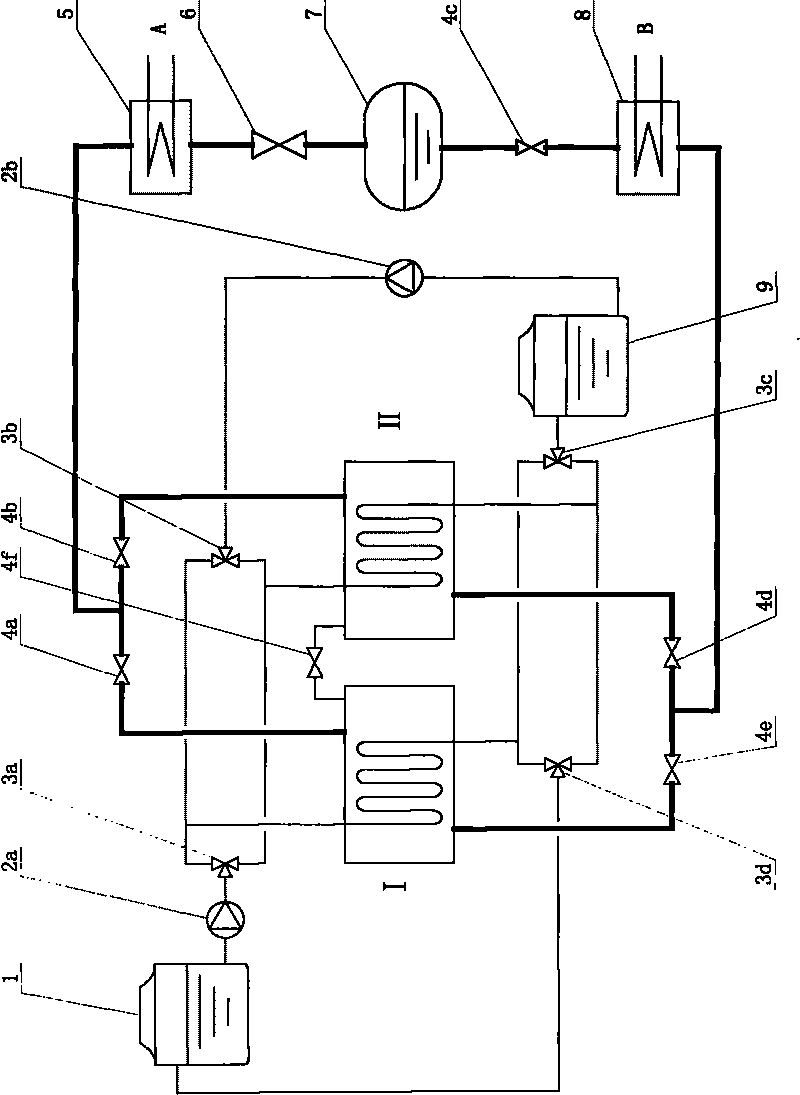

Image

Examples

Embodiment 1

[0032] The adsorber I and adsorber II used in the present invention are plate-fin heat exchangers with the same size and structure, and the fin units composed of fins and partitions are stacked and fixed inside, and one side of the fins is tightly packed. Solid adsorbent, the other side is the heat exchange fluid.

[0033] Select the liquid phase mixture of 51% (mass fraction) n-butane, 46% (mass fraction) isobutane and 3% (mass fraction) propane as refrigerant, coconut shell activated carbon is adsorbent, plate-fin heat exchanger is For the adsorber, the adsorption temperature is 30°C, the desorption temperature is 120°C, the evaporation pressure is 0.16MPa (corresponding to the saturation temperature of 5°C), the ambient temperature is 30°C, the condensation pressure is 0.36MPa, the desorption and adsorption processes are both 8min, and the return The heating time is 2 minutes, the mass recovery time is 1 minute, the cooling power of the system is 130W / kg, and the COP is 0.1...

Embodiment 2

[0042] The adsorber I and adsorber II used in the present invention are tube-fin heat exchangers with the same size and structure. The finned tubes composed of fins connected to the heat exchange tubes are arranged and fixed inside, and the solid adsorbent is tightly packed. The fin side is filled, and the heat exchange fluid is inside the heat exchange tube.

[0043] The liquid phase mixture of 90% (mass fraction) isobutane, 2% (mass fraction) ethane and 8% (mass fraction) propylene is refrigerant, 90% (mass fraction) apricot shell activated carbon and 10% (mass fraction) The ZSM-5 molecular sieve mixture with a silicon-aluminum ratio of 15 is the adsorbent, the tube-fin heat exchanger is the adsorber, the adsorption temperature is 45°C, the desorption temperature is 110°C, and the evaporation pressure is 0.29MPa (corresponding to the saturation temperature of 0°C) , the ambient temperature is 40°C, the condensation pressure is 0.77MPa, the desorption and adsorption processes...

Embodiment 3

[0045] The adsorber I and the adsorber II adopted in the present invention are plate-fin heat exchangers with the same size and structure.

[0046] The liquid phase mixture of 40% (mass fraction) isobutane and 60% (mass fraction) n-butane is refrigerant, 85% (mass fraction) super activated carbon, 10% (mass fraction) pure silicon molecular sieve Silicalite-1 and 5 % (mass fraction) of the hydrophobic silica gel mixture is the adsorbent, the plate-fin heat exchanger is the adsorber, the adsorption temperature is 30°C, the desorption temperature is 115°C, and the evaporation pressure is 0.10MPa (corresponding to the saturation temperature is -5°C), The ambient temperature is 35°C, the condensation pressure is 0.36MPa, the desorption and adsorption processes are both 8 minutes, the heat recovery time is 2 minutes, the mass recovery time is 1 minute, the system refrigeration power is 88W / kg, and the COP is 0.13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com