Chitosan nanofibre and preparation method and application thereof

A technology of chitosan nano and chitosan, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, medical science, etc., can solve problems such as complex processes, achieve simplified process steps, good biocompatibility, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

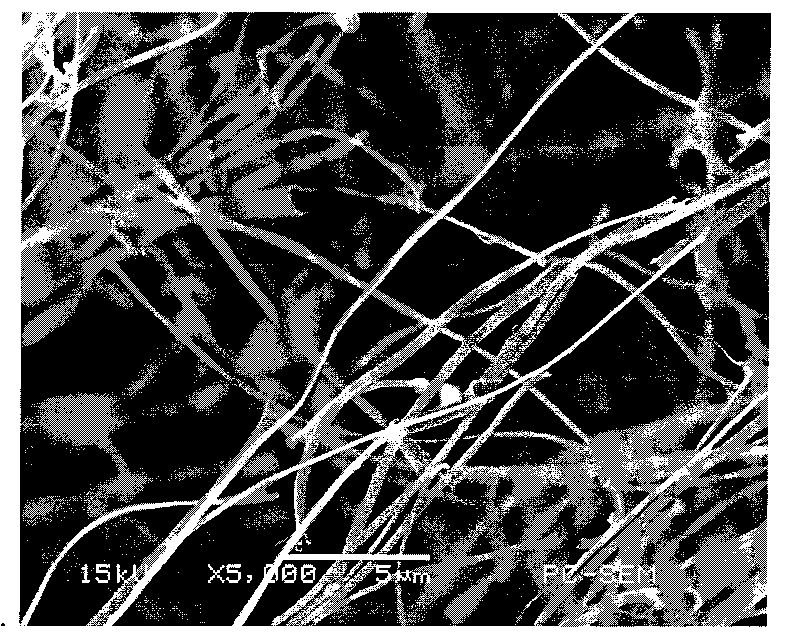

[0033] Weigh 0.1 gram of chitosan (90% degree of deacetylation, weight average molecular weight of 50,000) and dissolve it in 100 milliliters of 0.5% acetic acid solution, and magnetically stir at normal temperature to prepare a 0.1% chitosan acetic acid solution. The chitosan solution was placed in liquid nitrogen and frozen for 24h, and then freeze-dried for 7 days at -80°C. 10) and deionized water cleaning, then freeze-drying at -80°C for 7 days to obtain chitosan nanofibers, the diameter of which is 250-400nm, such as figure 1 shown.

Embodiment 2

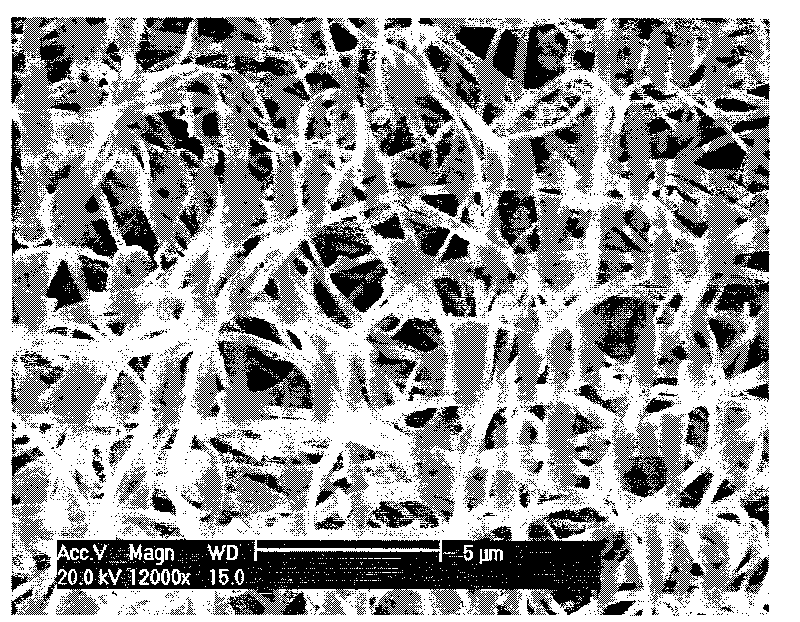

[0035] Weigh 0.05 gram of chitosan (degree of deacetylation 95%, weight average molecular weight is 350,000) and dissolve in 100 milliliters of 0.25% acetic acid solution, stir magnetically at normal temperature, and prepare a chitosan acetic acid solution with a concentration of 0.05%. The chitosan solution was placed in liquid nitrogen and frozen for 12 h, and then freeze-dried for 3 days at -80 ° C. The chitosan nanofibers obtained were successively washed with 0.5 mol / L NaOH ethanol aqueous solution (the volume ratio of ethanol to water was 95: 5) and deionized water cleaning, then freeze-drying at -80°C for 3 days to obtain chitosan nanofibers, with diameters between 150 and 350nm, such as figure 2 shown.

Embodiment 3

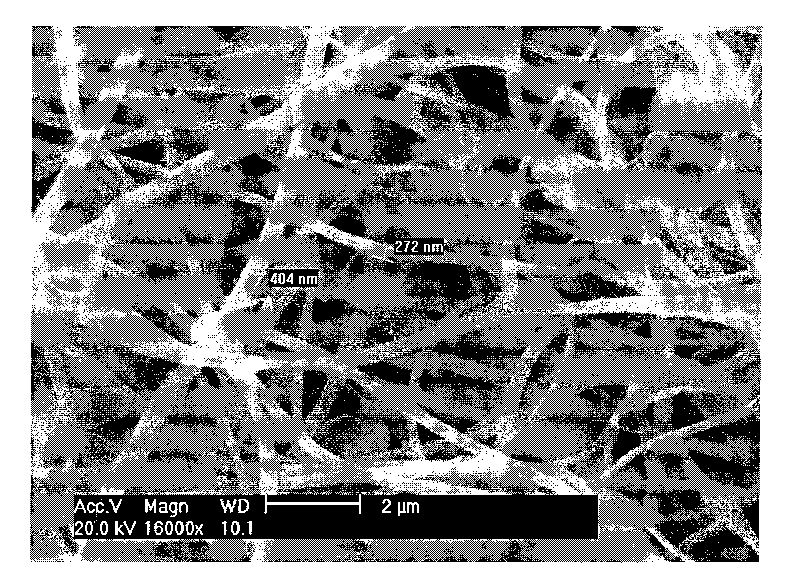

[0037] Weigh 0.01 gram of chitosan (95% degree of deacetylation, 1.5 million weight average molecular weight) and dissolve it in 100 milliliters of 0.005% hydrochloric acid solution, and magnetically stir at room temperature to prepare a 0.01% chitosan hydrochloric acid solution. The chitosan solution was frozen in liquid nitrogen for 1 min, and then freeze-dried at -80°C for 1 day to obtain nanofibers. After washing with deionized water and freeze-drying at -80°C for 1 day, chitosan nanofibers were obtained, with diameters ranging from 50 to 500 nm, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com