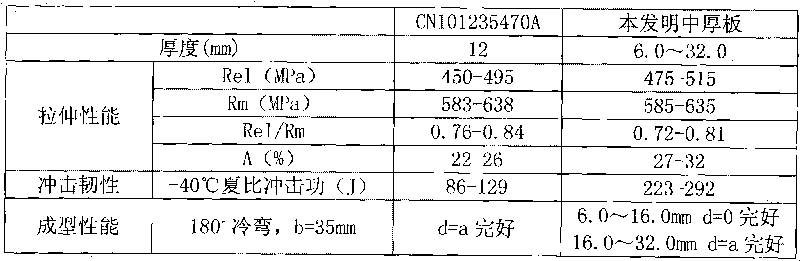

High-strength atmospheric corrosion-resistant medium plate and manufacturing method thereof

A technology of atmospheric corrosion resistance and manufacturing method, applied in the direction of manufacturing converters, metal rolling, etc., can solve the problems affecting the stable production and safe operation of railway vehicles, bending cracks, increasing the cost of steel, etc. The effect of low organization level, good molding performance, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

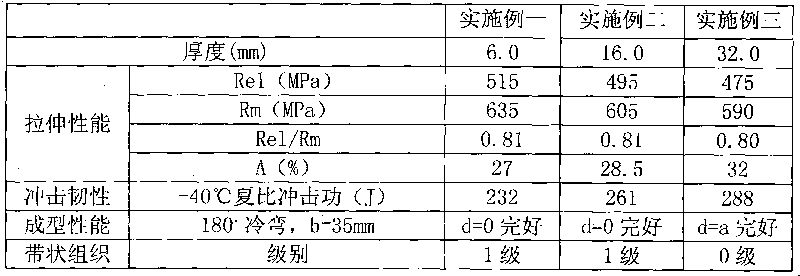

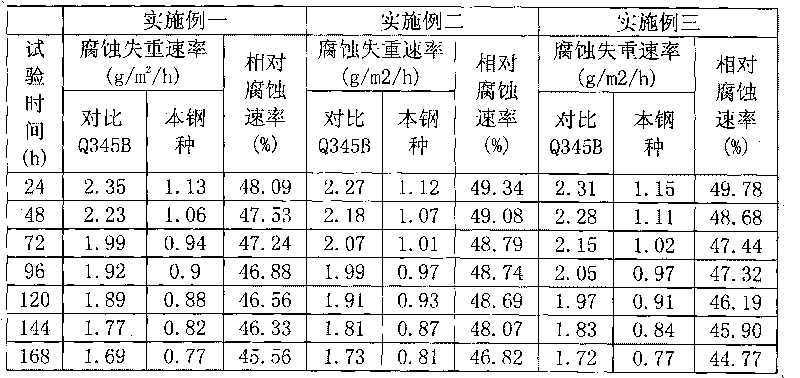

[0034] The specific implementation of the high-strength atmospheric corrosion-resistant medium-thick plate and its manufacturing method will be described in detail below in conjunction with the examples, but the specific implementation of the high-strength atmospheric corrosion-resistant medium-thick plate and its manufacturing method is not limited to the following examples.

[0035] The production conditions of the following examples are molten iron pretreatment facilities, a 180-ton top-bottom compound blowing converter, an LF refining device, a slab continuous caster, and a 3300mm medium-thick plate production line.

[0036] The chemical analysis method for atmospheric corrosion resistant medium and thick plates is GB / T 223, and the sampling method is GB / T 20066.

[0037] GB / T 228, GB / T 2975, sampling method for tensile properties of medium and thick plates resistant to atmospheric corrosion.

[0038] GB / T 229 test method for impact toughness of medium and thick plates res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com