A method for synthesizing polyhydroxyalkanoate by using water to treat excess sludge

A polyhydroxyalkanoate, excess sludge technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of large excess sludge output and cannot fundamentally reduce excess sludge Sludge, high moisture content, high yield, simple device and good operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: a kind of method of utilizing sludge to synthesize polyhydroxyalkanoate of the present invention, method step is as follows:

[0015] Step 1: Activated sludge inoculation: Take the remaining activated sludge from the sewage plant and put it into the SBR reactor. According to the general law of microbial growth, the organic acid waste liquid rich in small molecules is used as the carbon source. The ratio of phosphorus source is 100:5:1, adjust the nutrient ratio and pH, prepare the culture medium, activate and stabilize the excess sludge;

[0016] Step 2: Sludge activity recovery and biological selection stage: first run in complete aerobic mode, aerate for 5-7 days, wait until the sludge is in good condition, the color turns from brown black to light yellow, and after the activity is stable, enter The next cycle of domestication process, the purpose of this process is to restore biological activity as soon as possible, through balanced nutrition and long-t...

Embodiment 2

[0019] Embodiment 2: the inventive method realization process is as follows:

[0020] In the high-concentration organic wastewater treatment process, the first step is often treated by anaerobic hydrolysis acidification, fermentation and other processes. The COD of the effluent of these processes is still high and rich in a large number of small molecule organic acids. By adjusting the pH value and nutrient ratio, These organic acids can be used as good substrates for microorganisms to be cultivated, and the microorganisms can be domesticated to synthesize PHA.

[0021] The currently known bacteria with the ability to synthesize PHA are widely distributed, covering various genera such as Bacillus, Pseudomonas, and photosynthetic bacteria. The activated sludge used in the sewage treatment process of the sewage plant is a kind of In the stable biome system of metazoans, there are many PHA-synthesizing bacteria, but under the usual sewage treatment process conditions, the ability...

Embodiment 3

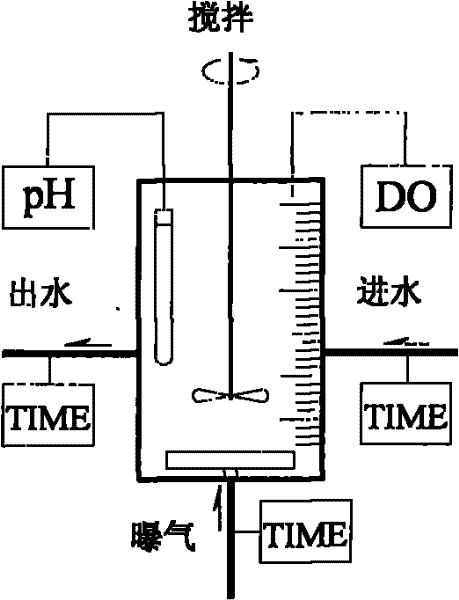

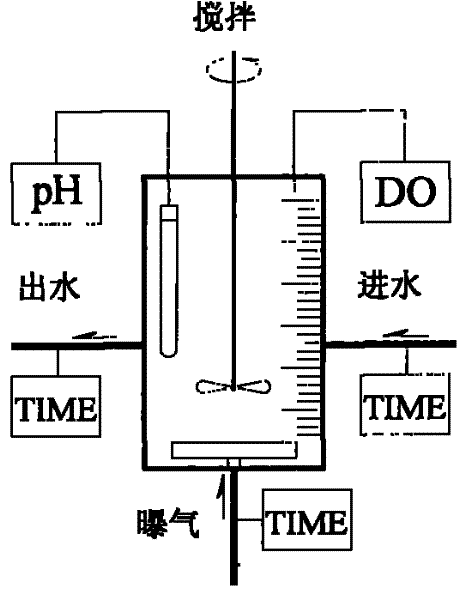

[0022] Example 3: Binding figure 1 , the device for realizing the method of the present invention such as figure 1 As shown, the device adopts an automatic control system, using a time controller (TIME) to control the inflow and outflow of water and the aerobic aeration process, and at the same time monitor its pH, dissolved oxygen (DO) and other parameters online.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com