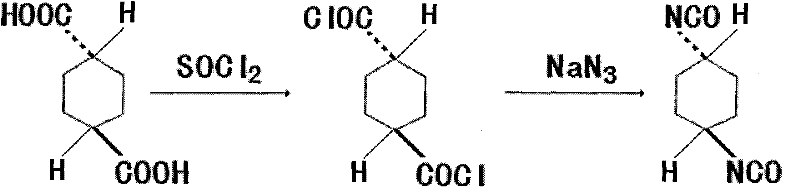

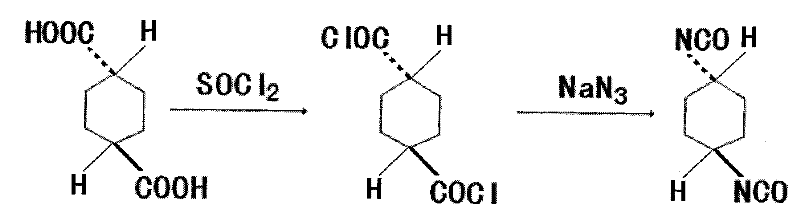

Synthetic method of trans-1,4-cyclohexane diisocyanate

A technology of cyclohexane diisocyanate and cyclohexane dicarboxylic acid, applied in the preparation of carboxylic acid nitrogen-containing derivatives, organic chemistry, etc., can solve the problems of short reaction cycle, achieve short reaction cycle, easy to obtain raw materials, and process route simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 172.18g trans-1,4-cyclohexanedicarboxylic acid (1mol), 440ml (6mol) thionyl chloride, add in the three-necked flask of reflux condenser, stirring, thermometer and tail gas absorption device, heat and reflux for 4 hours, The excess thionyl chloride was recovered under reduced pressure to obtain 199.5 g of crude trans-1,4-cyclohexanedicarbonyl chloride, with a yield of 94.99%.

Embodiment 2

[0020] 172.18g trans-1,4-cyclohexanedicarboxylic acid (1mol), 440ml (6mol) thionyl chloride, add in the three-necked flask of reflux condenser, stirring, thermometer and tail gas absorption device, heat and reflux for 3.5 hours, The excess thionyl chloride was recovered under reduced pressure to obtain 196.9 g of crude trans-1,4-cyclohexanedicarbonyl chloride, with a yield of 94.21%.

Embodiment 3

[0022] 172.18g trans-1,4-cyclohexanedicarboxylic acid (1mol), 440ml (6mol) thionyl chloride, add in the three-necked flask of reflux condenser, stirring, thermometer and tail gas absorption device, heat and reflux for 3 hours, The excess thionyl chloride was recovered under reduced pressure to obtain 186.7 g of crude trans-1,4-cyclohexanedicarbonyl chloride, with a yield of 89.33%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com