High-strength steel fibre castable

A technology of high-strength steel and castables, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high cost of corundum materials and high raw material costs of enterprises, and achieve good thermal shock resistance, Effect of high load softening temperature, high compressive strength and flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

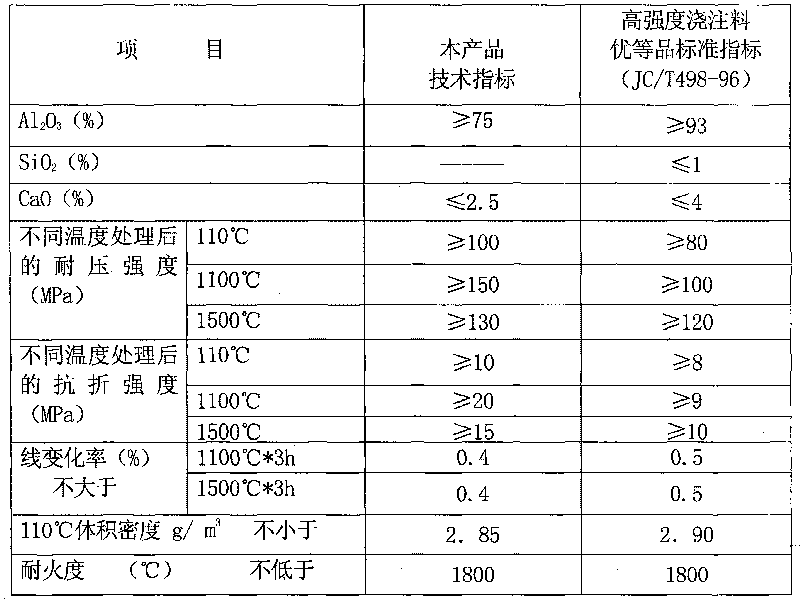

Image

Examples

Embodiment Construction

[0015] The high-strength steel fiber castable according to the present invention is made of raw materials bauxite, brown corundum, alumina micropowder, silicon carbide, silicon micropowder, CA-70 cement, No. 446 heat-resistant steel fiber, explosion-proof steel fiber and three Sodium polyphosphate and sodium hexametaphosphate are formulated according to the following parts by weight:

[0016] 2.5 parts of bauxite materials with a particle size of 8-5mm, 2.3 parts of bauxite materials with a particle size of 0.075mm<5mm, 2 parts of brown corundum particles with a particle size of 3-1mm, 0.8 parts of bauxite materials with a particle size of ≤0.075mm, and a particle size of ≤0.025mm 0.4 part of alumina superfine powder, 0.6 part of silicon carbide powder with particle size ≤0.075mm, 0.3 part of silicon carbide powder with particle size<0.019mm, 0.6 part of CA-70 cement, 0.5 part of brown corundum powder with particle size<0.053mm, heat-resistant steel No. 446 0.2 part of fiber, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com