Bent-tube heating furnace

A bending tube heating and heating chamber technology, applied in the field of spiral energy-saving lamp manufacturing machinery, can solve the problems of slow temperature adjustment, difficult softening and adhesion of lamp tubes, uneven heating, etc., achieve fast cooling speed, avoid adverse effects, and increase production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

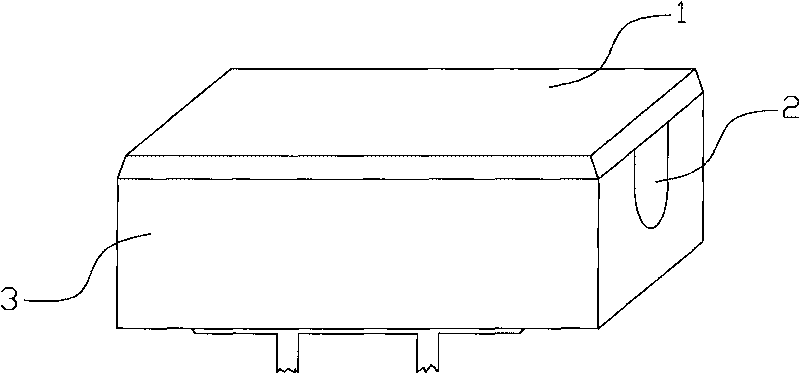

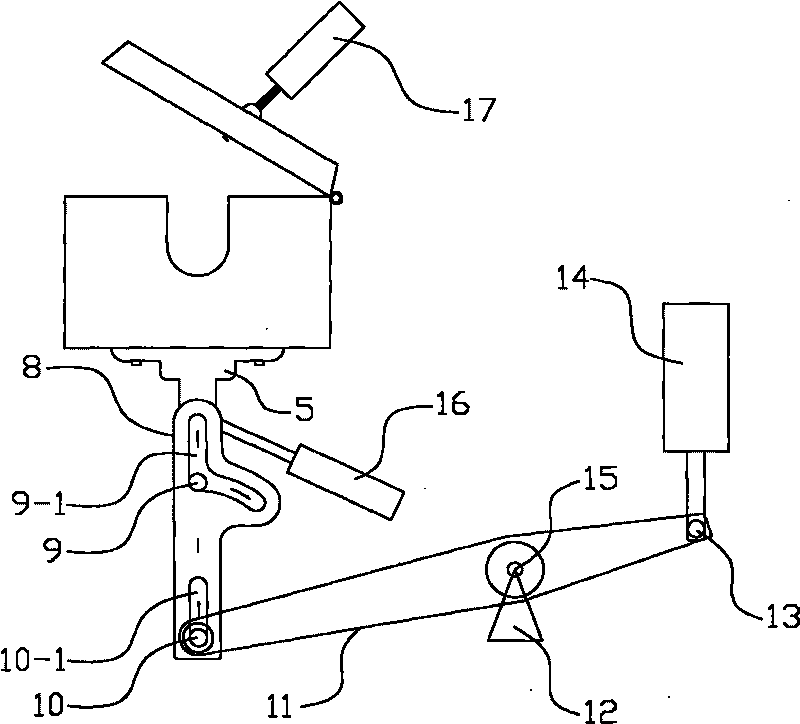

[0017] Elbow heating furnace such as Figure 1~2 As shown, it includes a double-layer structure with a furnace body 3 with a heating chamber. A furnace cover 1 is pivotally connected to the furnace body, and the furnace cover 1 is connected to a cover-opening cylinder 17 that can drive it to rotate around the shaft connection end 3-1. , the double-layer structure is a graphite layer 7 with a U-shaped cross-section and an insulating layer 6 of glass fiber material wrapped outside the graphite layer 7, and the heating chamber is a heating groove 2 formed by a U-shaped concave part of the graphite layer 7. Both ends of the heating tank are open. In addition, the present invention can also add the following technical features to make the bent pipe heating furnace more perfect.

[0018] Described body of furnace 3 is fixed on a base 5 with bolt 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com