Process for removing impurities in production of dry-method aluminum fluoride

An aluminum fluoride and process technology, applied in aluminum fluoride, aluminum halide, fluorine/hydrogen fluoride, etc., can solve the problems of environmental pollution and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

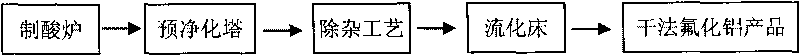

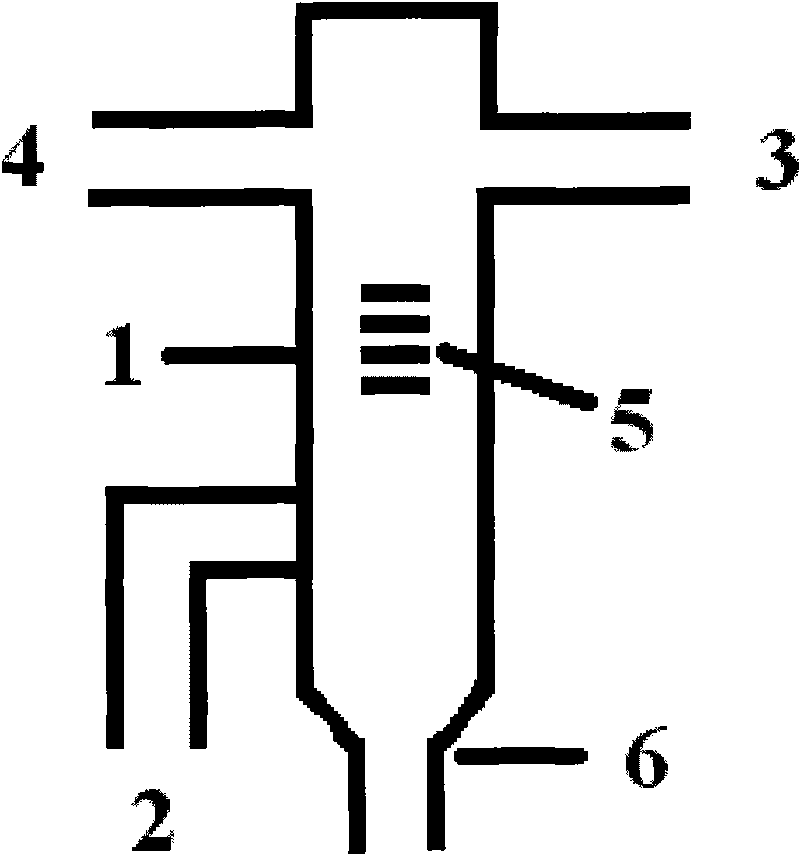

[0017] Using three-grade fluorite (according to the national standard for fluorite ore quality GB5690-85) and oleum (mass concentration: 125%) in the acid furnace through reaction (reaction conditions are carried out according to conventional industrial methods) to produce various impurities The hydrogen fluoride gas is introduced into the impurity removal process through the inlet pipe, and then anhydrous hydrogen fluoride gas is sent out from the gas outlet, and finally enters the fluidized bed to react with aluminum hydroxide (reaction conditions are carried out according to conventional industrial methods), thereby obtaining dry aluminum fluoride products. Its performance parameters are superior to the indicators of the first-class products stipulated by the state (according to the AF-1 level in the national standard GB / T4292-2007). During the operation of the impurity removal process, it is purged by the backflushing device every 2 hours, and the purging time is 2 minutes....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com