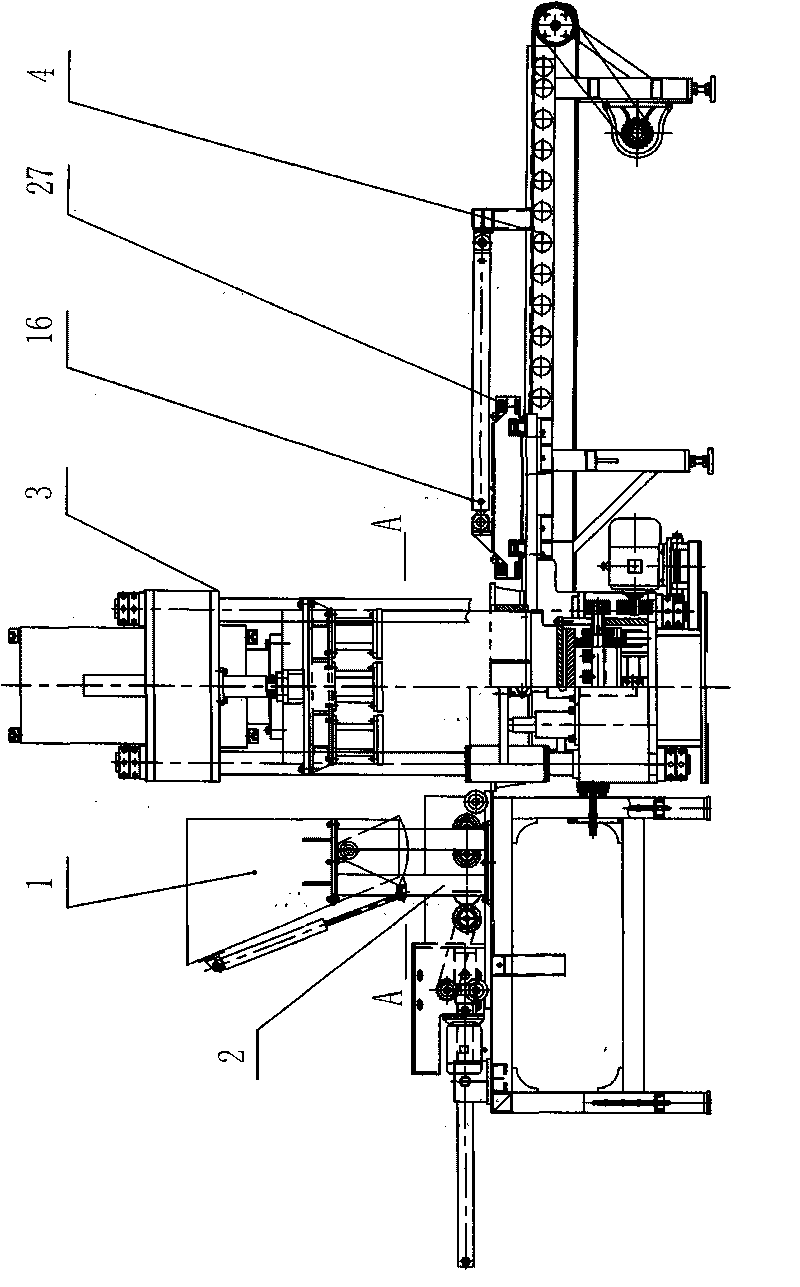

Multi-functional two-way pressurization and vibration brick making machine

A technology of two-way pressurization and brick making machine, which is used in manufacturing tools, ceramic molding machines, etc., to shorten the molding cycle, reduce noise, and achieve good product compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

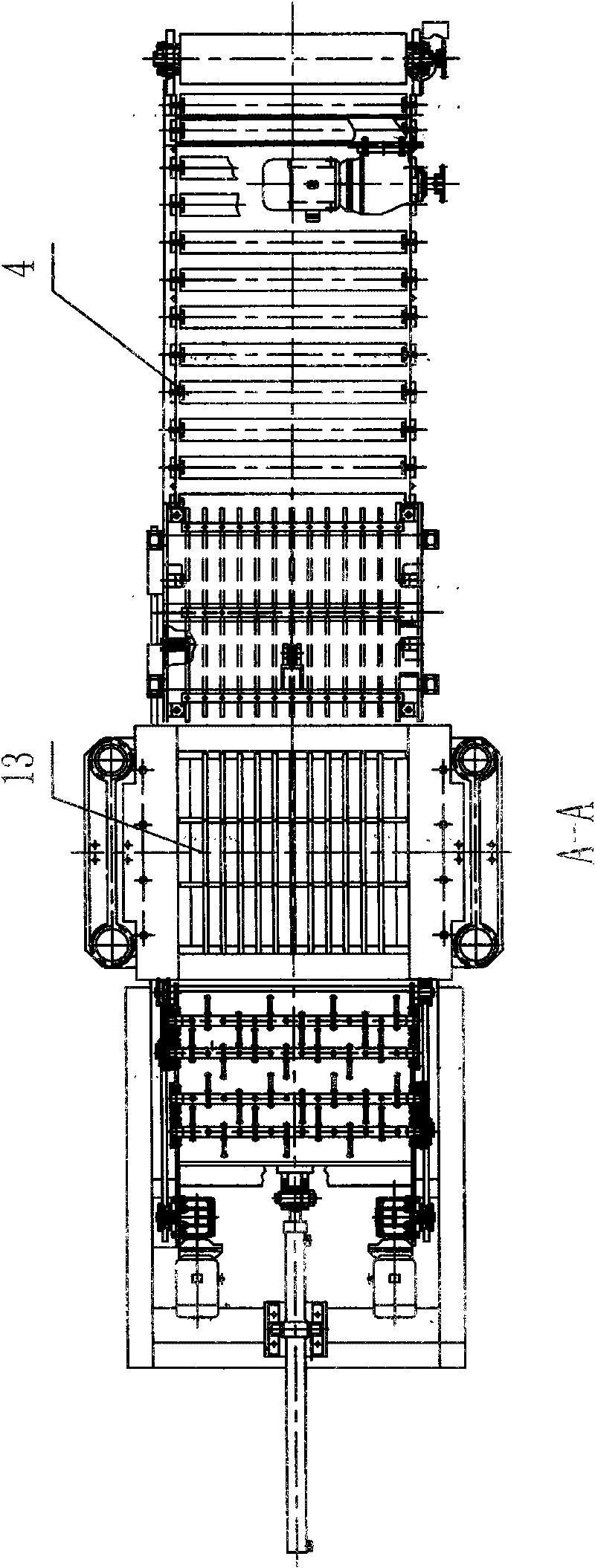

[0022] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 , 2 , The multi-functional two-way pressurized vibration brick making machine shown in 3 and 4 includes a storage hopper 1, a material distributing mechanism 2, a main machine 3, a brick discharging mechanism 4, a hydraulic station and an automatic control device for the whole machine, the main machine of the brick making machine The frame is provided with an upper beam 5, a column 6, and a lower beam 7, and is characterized in that: the upper beam 5 is equipped with an upper pressure head main oil cylinder 8, an upper pressure head auxiliary oil cylinder 9; an upper pressure head main oil cylinder 8 and an upper pressure head The bottom of the auxiliary oil cylinder 9 is equipped with an upper moving mechanism 10, the lower part of the upper moving mechanism 10 is equipped with an upper mold base 11, the bottom of the upper mold base 11 is equipped with an upper mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com