Super-hydrophobic polypropylene film and preparation method thereof

A polypropylene film and super-hydrophobic technology, applied in the field of super-hydrophobic polypropylene film and its preparation, can solve the problems of low surface energy, restrict the application of super-hydrophobic surface, etc., achieve good structural stability, good industrial application prospects, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

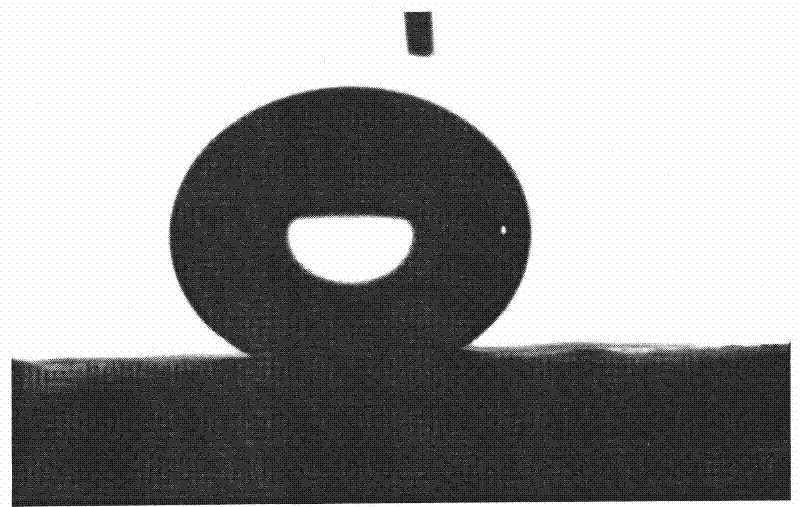

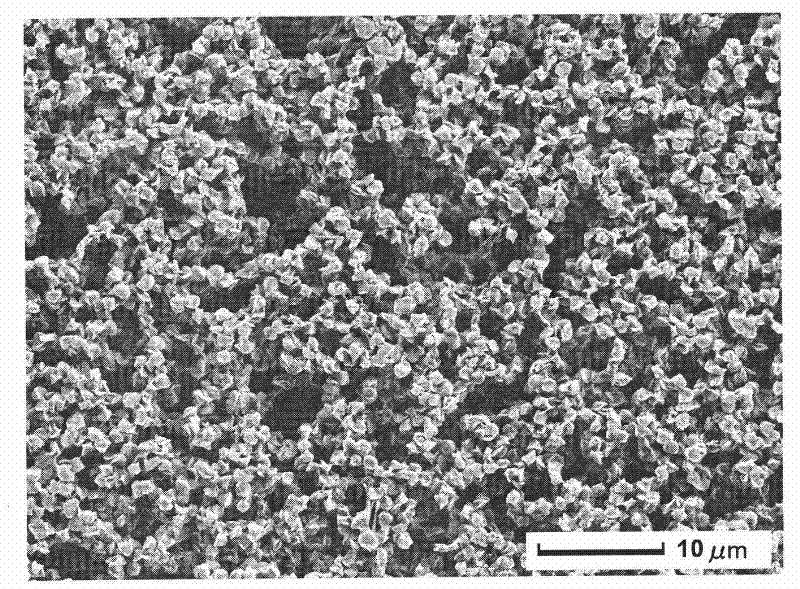

[0020] First, pretreat the glass flake by immersing it in a solution of concentrated sulfuric acid and 30wt% hydrogen peroxide in a volume ratio of 7:3 for 1 hour, then take it out, rinse it with deionized water, and dry it with nitrogen to obtain a pretreated clean glass flake. Then take a certain amount of isotactic polypropylene particles and add them to xylene, stir at 130°C for 30 minutes to form a 1 mg / mL polypropylene solution, then add acetone that is 20% of the volume of the polypropylene solution and stir, then use In the casting method, the acetone-added polypropylene solution is spread on the glass substrate, and after natural drying at 20°C for 12 hours, a white polypropylene film is formed on the glass surface. see figure 1 , using OCAH200 contact angle tester to test the wettability of the film surface, the results show that the contact angle of the surface with water is 152°, and the rolling angle is less than 4°. The surface morphology of the film was observe...

Embodiment 2

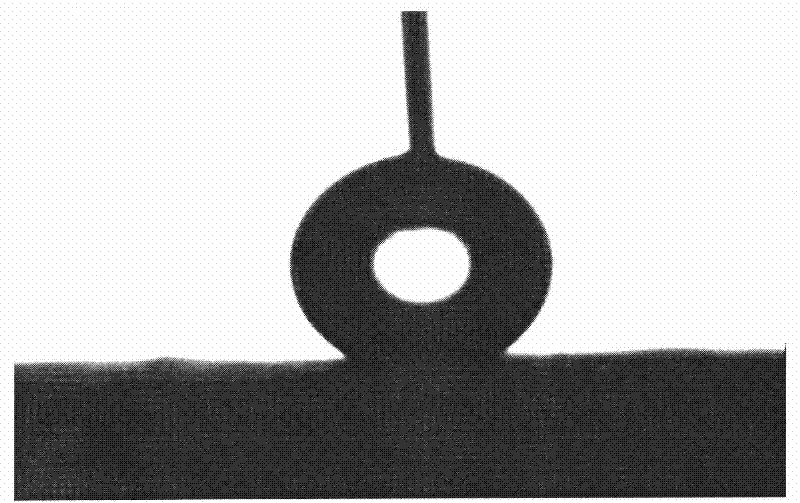

[0022] First, pretreat the glass flake by immersing it in a solution of concentrated sulfuric acid and 30wt% hydrogen peroxide in a volume ratio of 7:3 for 1 hour, then take it out, rinse it with deionized water, and dry it with nitrogen to obtain a pretreated clean glass flake. Then take a certain amount of isotactic polypropylene particles and add them to xylene, stir at 130°C for 30 minutes to form a 25 mg / mL polypropylene solution, then add acetone that is 40% of the volume of the polypropylene solution and stir, then use The polypropylene solution added with acetone is flowed on the glass substrate by casting method, and after vacuum drying at 70°C for 3 hours, a white polypropylene film is formed on the glass surface. see image 3 , using OCAH200 contact angle tester to test the wettability of the film surface, it shows that the contact angle between the surface and water is 174°, and the rolling angle is less than 4°. The surface morphology of the film was observed by ...

Embodiment 3

[0024] First, pretreat the glass flake by immersing it in a solution of concentrated sulfuric acid and 30wt% hydrogen peroxide in a volume ratio of 7:3 for 1 hour, then take it out, rinse it with deionized water, and dry it with nitrogen to obtain a pretreated clean glass flake. Then take a certain amount of isotactic polypropylene particles and add them to xylene, stir at 130°C for 30 minutes to form a 50 mg / mL polypropylene solution, then add acetone that is 60% of the volume of the polypropylene solution and stir for 3 minutes, then The polypropylene solution added with acetone was flowed on the glass substrate by casting method, and after vacuum drying at a temperature of 45°C for 3 hours, a white polypropylene film was formed on the glass surface. OCAH200 contact angle tester was used to test the wettability of the surface of the film, and the results showed that the contact angle between the surface and water was 160°, and the rolling angle was less than 4°. The surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com