Reaction kettle for suspension stirring type chemical engineering

A technology of suspension stirring and reaction kettle, which is applied in chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of product quality decline and uniform dispersion of material and liquid that cannot be poured later. , product performance changes and other issues, to reduce the production of by-products, improve product quality, and improve mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

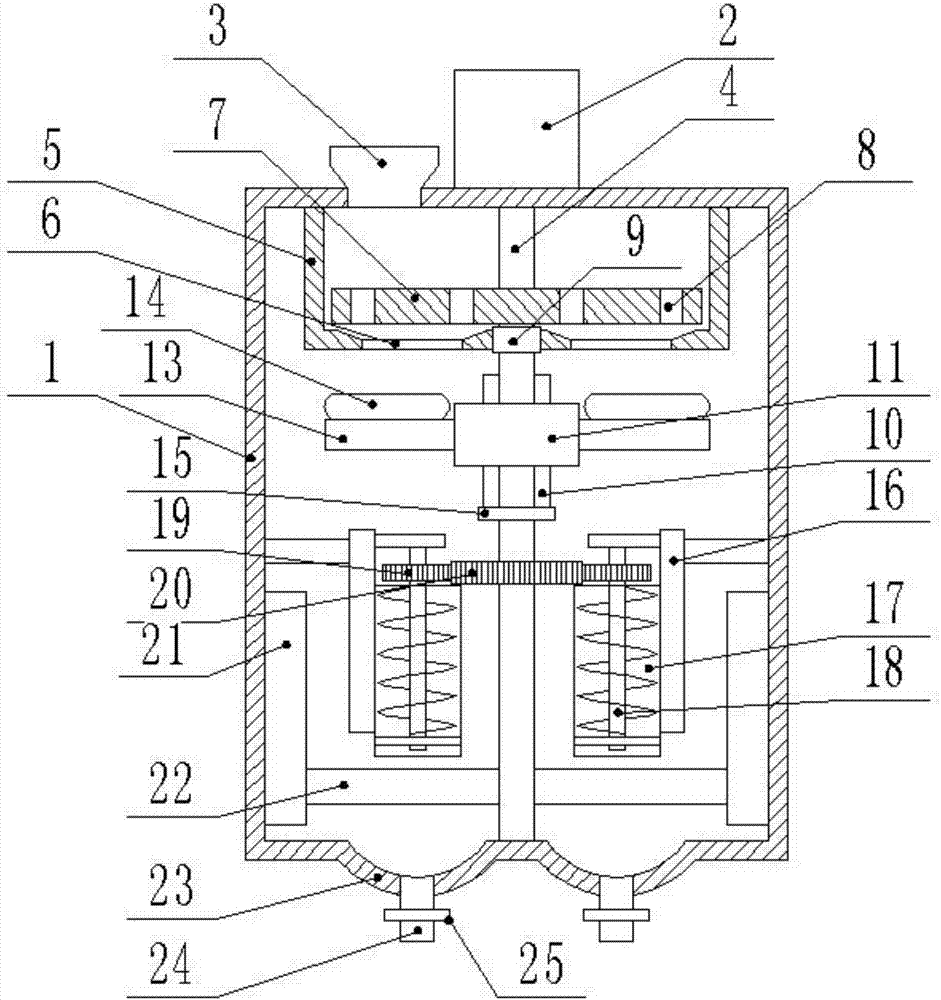

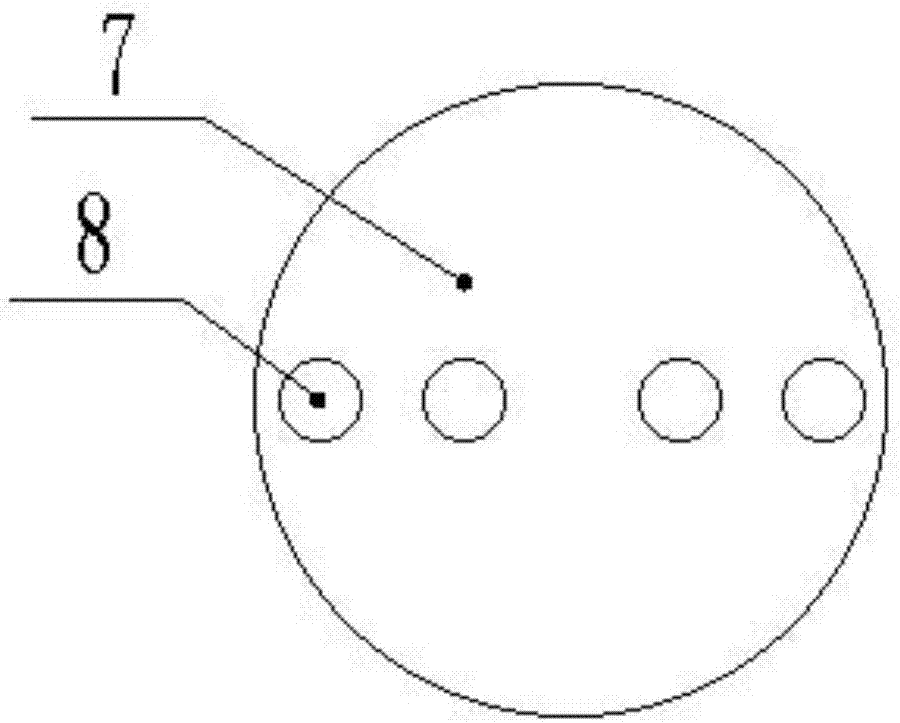

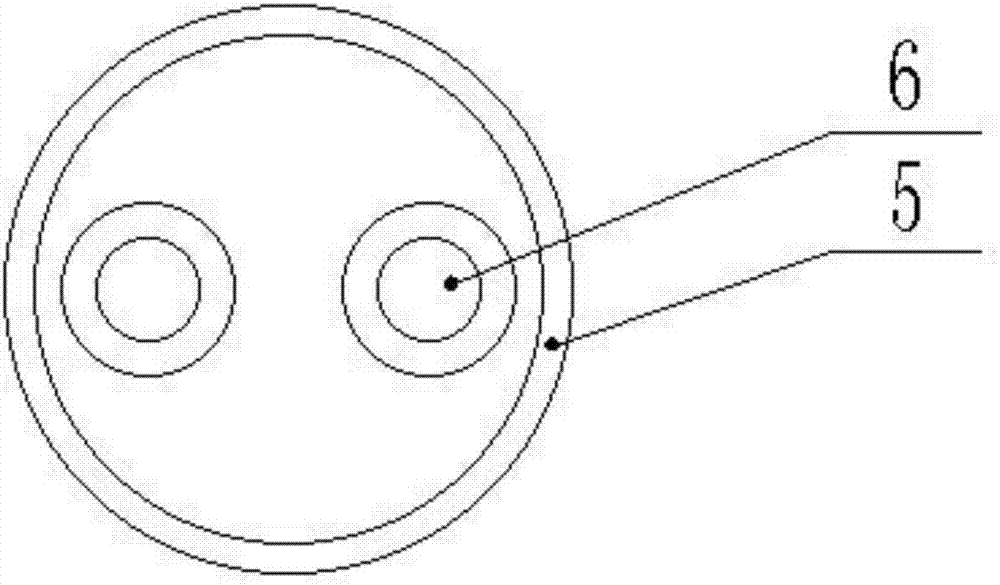

[0020] Please refer to the figure, in the embodiment of the present invention, a suspension stirring type chemical reaction kettle includes a kettle body 1, a motor 2, a feed hopper 3 and a liquid outlet pipe 24; the motor 2 is fixedly installed on the top of the kettle body 1 , the output shaft of the motor 2 extends vertically downwards into the kettle body 1, and the output shaft lower end of the motor 2 is fixedly connected with a vertical transmission shaft 4, and the lower end of the transmission shaft 4 is connected to the bottom of the kettle body 1 in rotation; The top in the kettle body 1 is fixed with a blanking box 5, and the transmission shaft 4 passes through the blanking box 5, and the transmission shaft 4 is connected with the blanking box 5 by bearings 9. On the transmission shaft 4 in the blanking box 5, the same The shaft is fixed with a horizontal turntable 7, the diameter of which is 2 to 4mm smaller than the inner diameter of the blanking box 5, and a vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com