Convenient-to-clean anti-noise high-stirring-force chemical reaction tank

A chemical reaction and stirring force technology, which is applied in chemical/physical/physical chemical fixed reactors, mixer accessories, mixers with rotating stirring devices, etc., can solve problems affecting work efficiency, loud vibration, slow response, etc. , to achieve the effect of speeding up the reaction speed, reducing noise and efficient stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

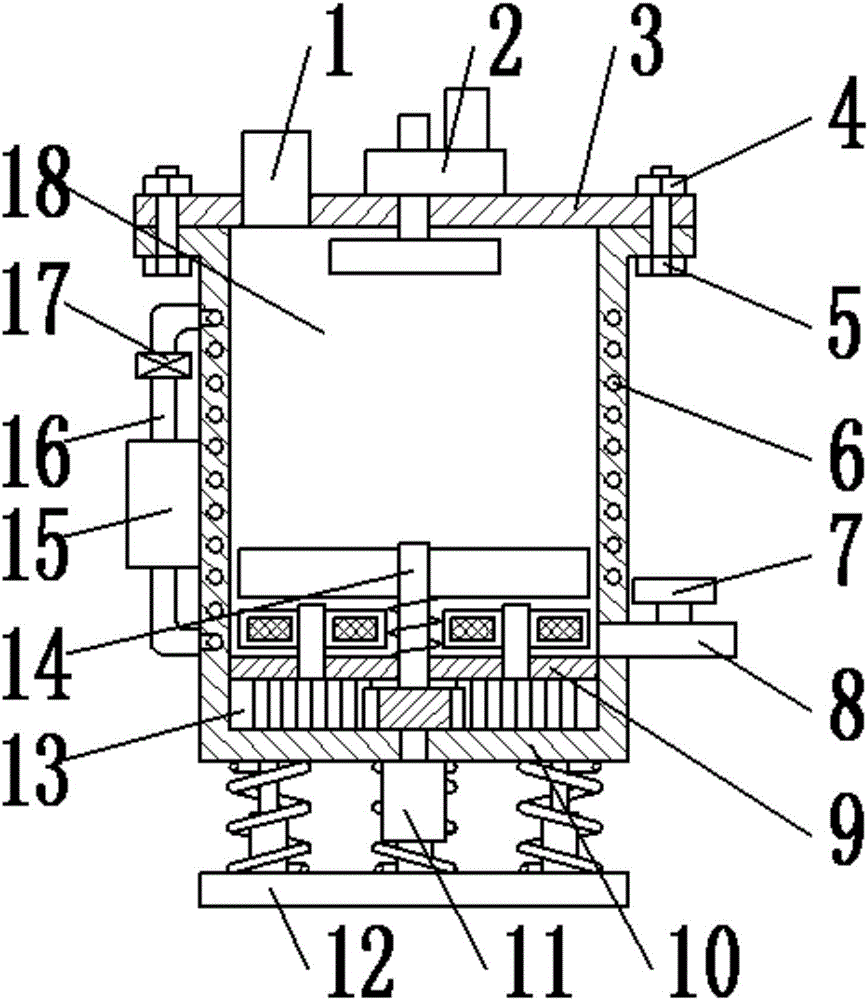

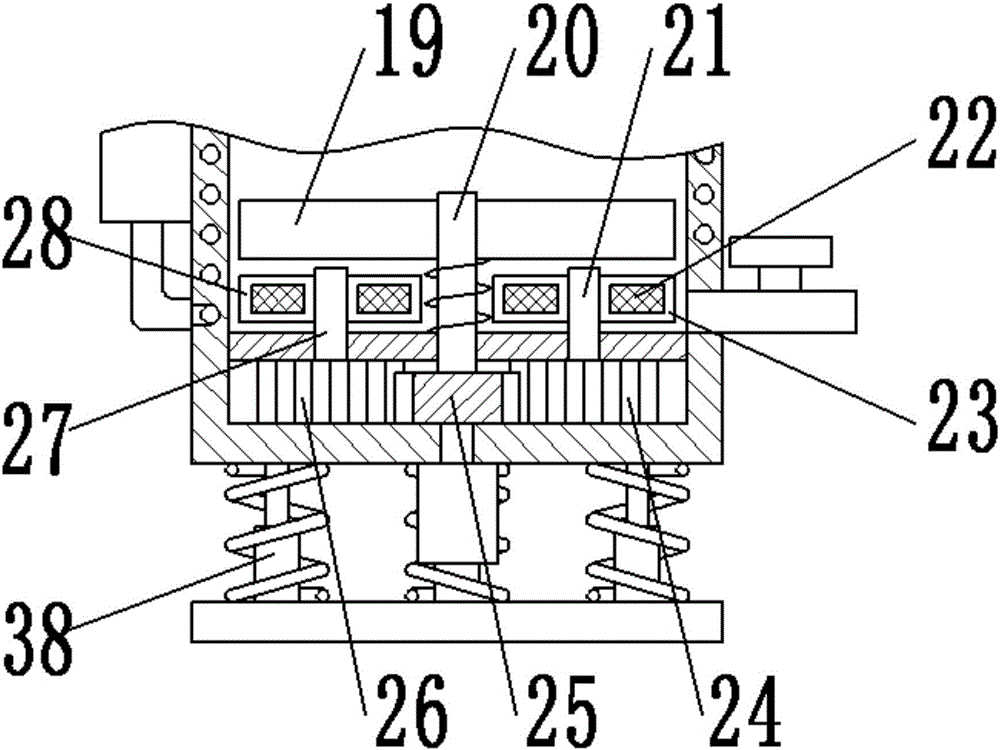

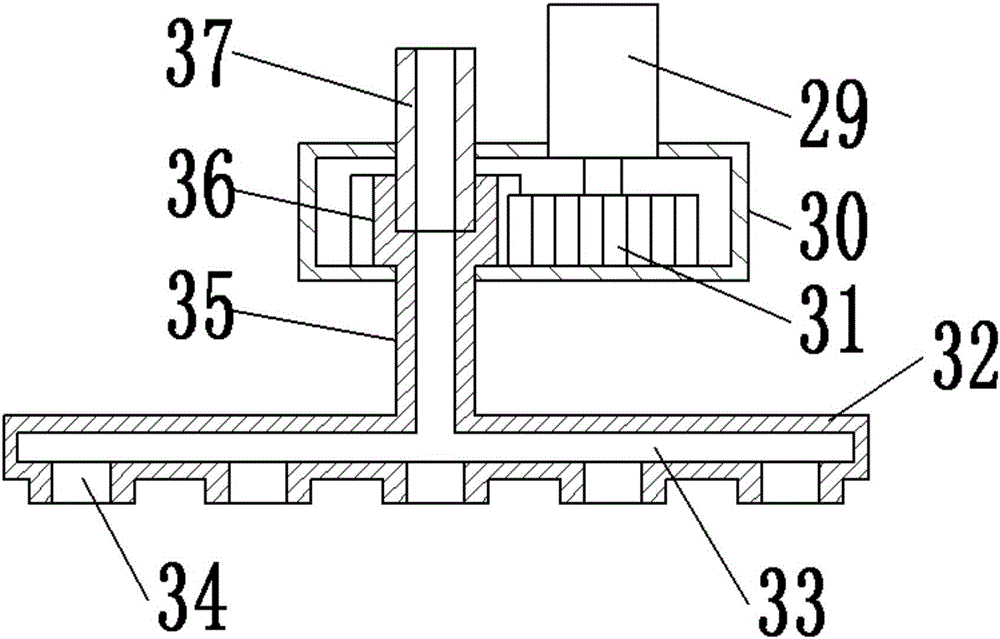

[0017] see Figure 1-4 , a noise-proof type high-stirring power chemical reaction tank that is easy to clean, including a reaction tank 10; the reaction tank 10 is set as a cylinder, and a top opening is provided with a top cover 3; the top cover 3 is passed through bolts 5 and nuts The mutual screwing of 4 is fixedly connected with the reaction tank 10; the upper cover 3 is provided with a feeding pipe 1 and a cleaning device 2; the feeding pipe 1 is arranged on the left side of the upper cover, which is convenient for adding chemical materials to the reaction tank 10; The cleaning device 2 is arranged in the middle part of the upper cover 3, and is composed of a transmission box 30, a rotating motor 29 and a rotating spray plate 32; the transmission box 30 is provided with a fourth gear 31 and a fifth gear 36; the fourth gear 31 It is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com