Temperature control method of glue dispenser

A temperature control method and glue dispenser technology, applied in electrical components, liquid injection devices, injection devices, etc., can solve problems such as affecting the glue output and affecting the processing quality of parts 4

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

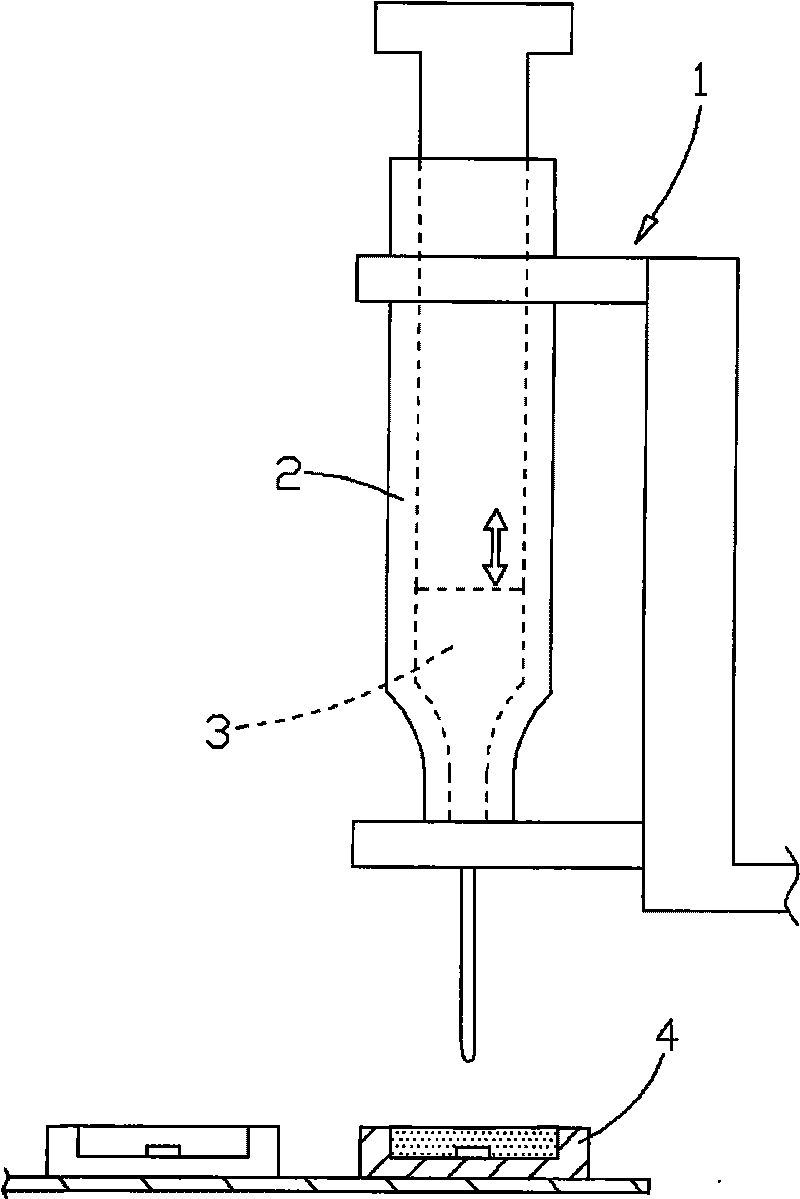

[0022] In order to make your examiner understand the main technical content and implementation mode of the present invention, the description is as follows with the help of drawings:

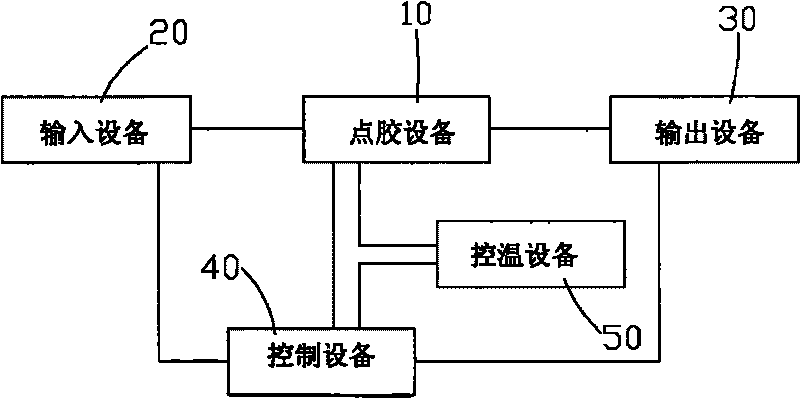

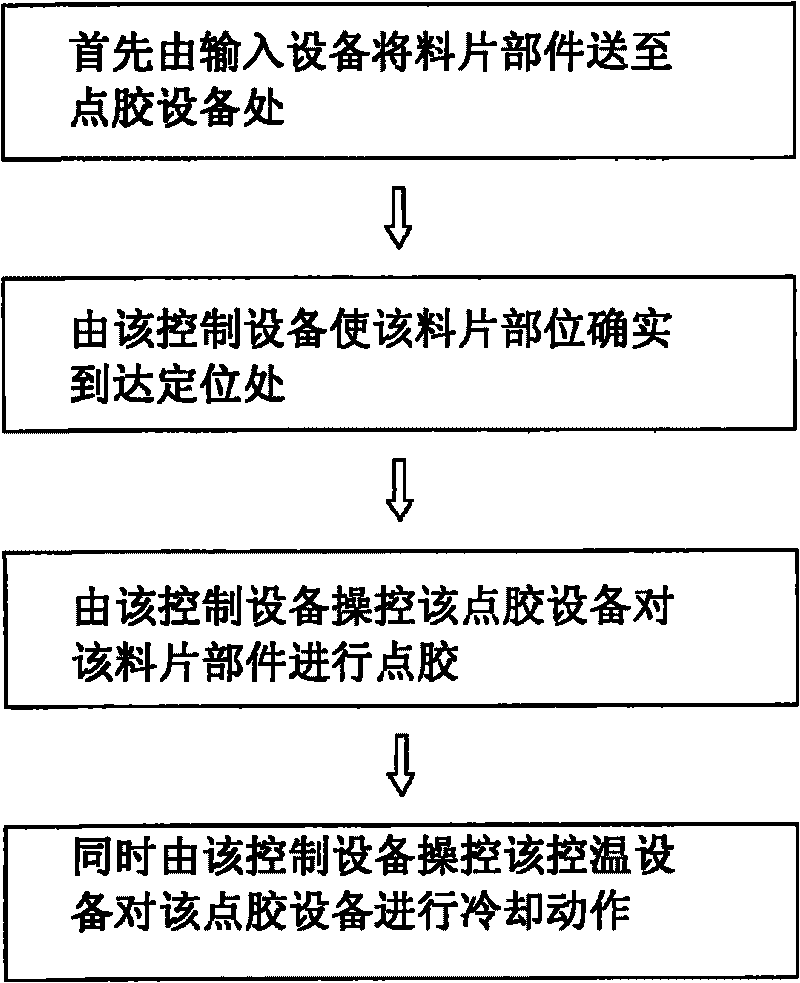

[0023] Such as figure 2 As shown, the dispenser used in the dispenser temperature control method of the present invention is provided with a dispensing device 10 for dispensing the tablet parts, and an input device 20 is provided for sending the tablet parts into the dispensing device 10, an output device 30 is provided to remove the material sheet parts that have completed the dispensing action from the dispensing device 10, and a control device 40 is provided to integrate and control the dispensing device 10, the input device 20 and the output device 30 operation.

[0024] The glue dispensing machine temperature control method of the present invention is mainly provided with a temperature control equipment 50 controlled by the control equipment 40, and the glue dispensing equipment 10 is coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com